Stamping Process

Stamping is a process in which a press is used at room temperature and a metallic material is sheared by a mold to deform it to obtain a desired shape.

Punching machine belongs to the category of forging presses. Cold stamping presses include mechanical presses and hydraulic presses. Commonly used is a mechanical press (punch).

Stamping Process

(1) Blanking Cutting

Blanking: The process of separating the embryos of a workpiece from the material along a closed contour.

(2) Punching

Punching: The process of separating the waste from the workpiece along the closed contour to obtain the required holed part.

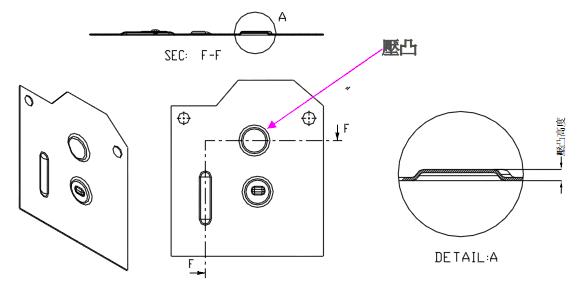

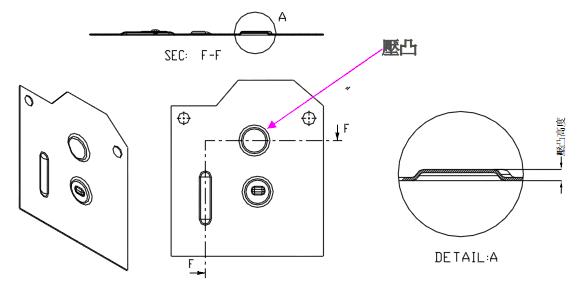

(3) Convex/Compression Embossing

Convex/Compression: A stamping process that uses a punch to squeeze into one side of the workpiece to force material into the opposite pocket to form a bump.

Uses: a) enhance product strength b) replace other components

(4)Bending

Bending is the method of forming a piece of material into a piece with a certain angle and shape. The material undergoes bending deformation under the action of the mold.

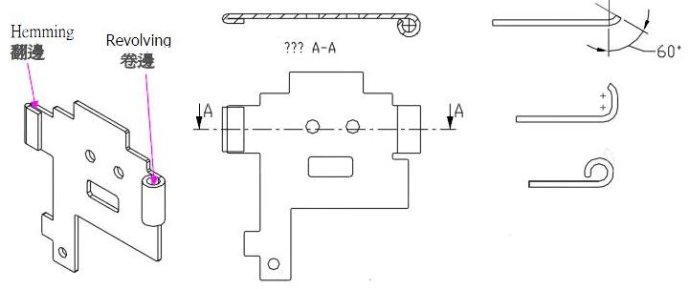

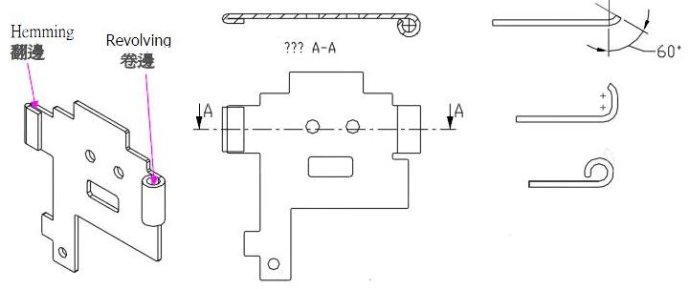

(5) Curling and Flanging Revolving and Hemming

Crimping: Circular crimping is performed on the ends of plates, cylinders or round containers or round containers.

Flange: Flanging is a stamping process in which the material is turned into a short lateral edge along the contour curve.

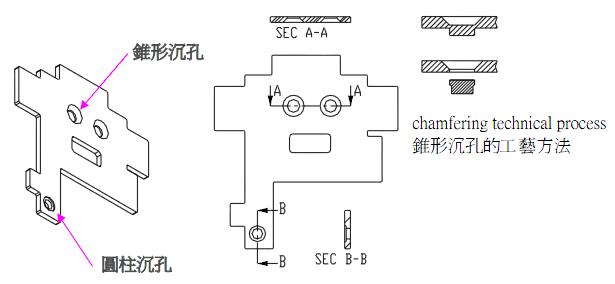

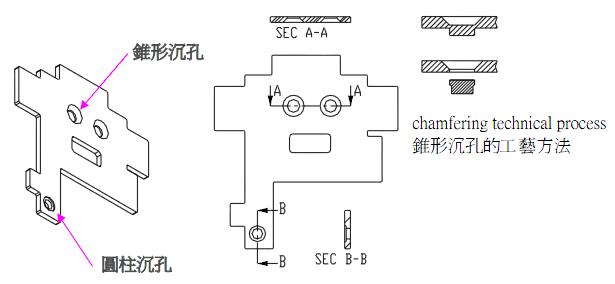

(6) Counterbored hole: A tapered counterbore or a cylindrical counterbore can be pressed out on the side of the hole by means of a mold. Generally used to assemble countersunk screws or to remove burrs

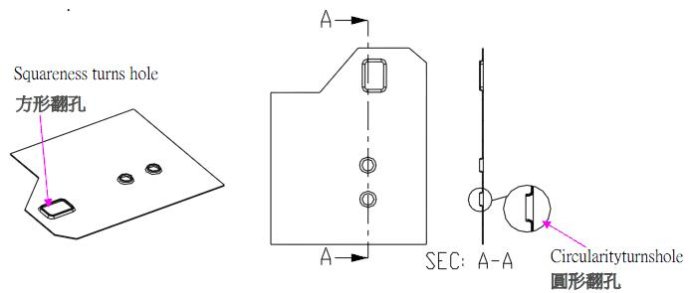

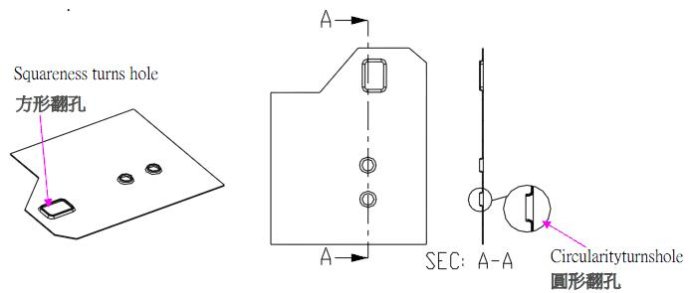

(7) Turns Hole

Along the circular inner periphery, the material is translated into its side flange stamping process, It is generally used for a sheet, tapping hole.

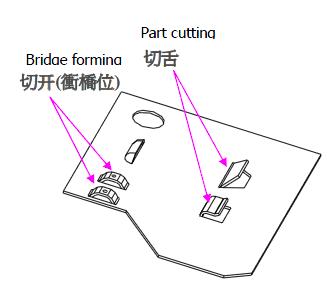

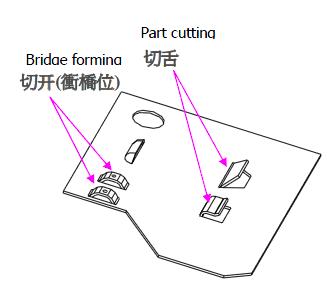

(8) Part Cutting & Bridge Forming

Part Cutting: The material was partially separated along the contour, but not completely separate stamping process. The partially separated material has a certain position required by the workpiece and is no longer located on the plane before the separation.

Bridge Forming: A stamping process that separates the material locally along the open profile rather than being completely separated. The material that is cut apart and separated is located or substantially in the plane where it was separated.

9) Deburring

Use the mold to remove sharp burrs from the cut.

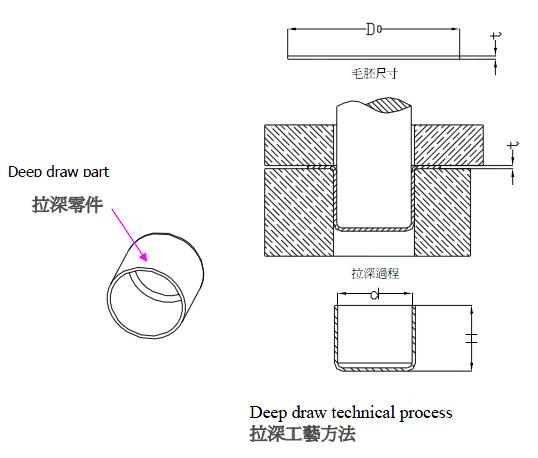

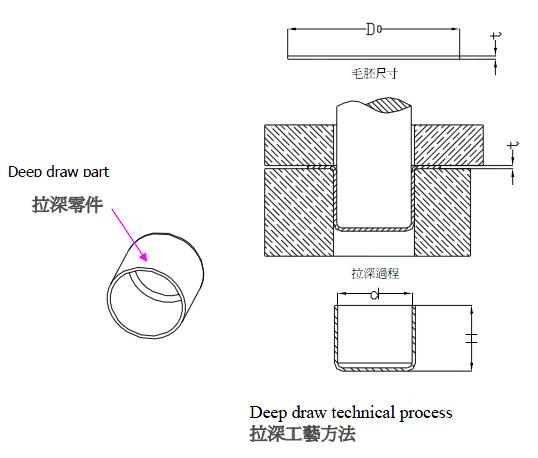

(10) Deep Draw

A stamping process that transforms straight or workpiece into hollow parts, or further changes the shape and size of hollow parts.

When deep drawing, the hollow member mainly depends on the material located outside the bottom of the punch and flows into the die.

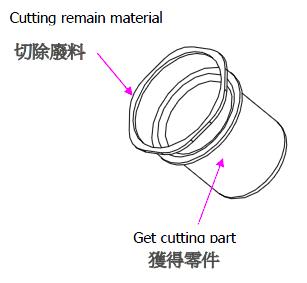

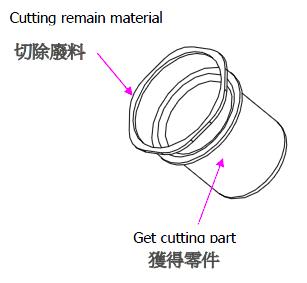

(11) Cutting

To obtain the precise shape of the part, according to a predetermined cutting lines cut wa

Punching machine belongs to the category of forging presses. Cold stamping presses include mechanical presses and hydraulic presses. Commonly used is a mechanical press (punch).

Stamping Process

(1) Blanking Cutting

Blanking: The process of separating the embryos of a workpiece from the material along a closed contour.

(2) Punching

Punching: The process of separating the waste from the workpiece along the closed contour to obtain the required holed part.

(3) Convex/Compression Embossing

Convex/Compression: A stamping process that uses a punch to squeeze into one side of the workpiece to force material into the opposite pocket to form a bump.

Uses: a) enhance product strength b) replace other components

(4)Bending

Bending is the method of forming a piece of material into a piece with a certain angle and shape. The material undergoes bending deformation under the action of the mold.

(5) Curling and Flanging Revolving and Hemming

Crimping: Circular crimping is performed on the ends of plates, cylinders or round containers or round containers.

Flange: Flanging is a stamping process in which the material is turned into a short lateral edge along the contour curve.

(6) Counterbored hole: A tapered counterbore or a cylindrical counterbore can be pressed out on the side of the hole by means of a mold. Generally used to assemble countersunk screws or to remove burrs

(7) Turns Hole

Along the circular inner periphery, the material is translated into its side flange stamping process, It is generally used for a sheet, tapping hole.

(8) Part Cutting & Bridge Forming

Part Cutting: The material was partially separated along the contour, but not completely separate stamping process. The partially separated material has a certain position required by the workpiece and is no longer located on the plane before the separation.

Bridge Forming: A stamping process that separates the material locally along the open profile rather than being completely separated. The material that is cut apart and separated is located or substantially in the plane where it was separated.

9) Deburring

Use the mold to remove sharp burrs from the cut.

(10) Deep Draw

A stamping process that transforms straight or workpiece into hollow parts, or further changes the shape and size of hollow parts.

When deep drawing, the hollow member mainly depends on the material located outside the bottom of the punch and flows into the die.

(11) Cutting

To obtain the precise shape of the part, according to a predetermined cutting lines cut wa