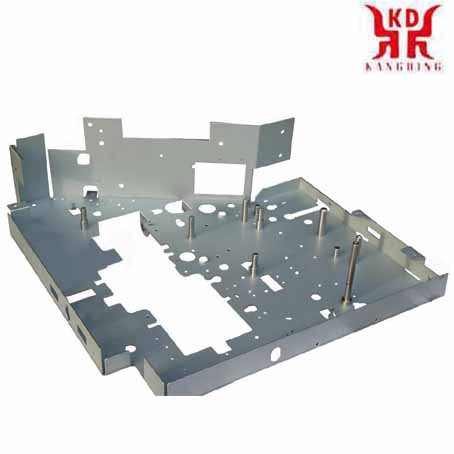

Manufacturing of Sheet Metal Parts

Production of sheet metal parts - which methods are used?

Sheet metal is a material of very different structure, thickness and shape. The sheet metal is also used everywhere. Sheets are used for roofs, gutters, building construction elements, machines, devices, vehicles and in many other areas of the economy. The multitude of uses of the sheet metal is connected with many methods of its processing, which allow the material to be adapted to the individual needs and requirements of the implemented project.Typically, a sheet metal part is considered to be a part made from a sheet of material of uniform thickness. When designing small objects, this material is usually thin. However, in KANGDING you can use the sheet metal commands in any design where the material has a uniform thickness.

Production of sheet metal parts in a modern way

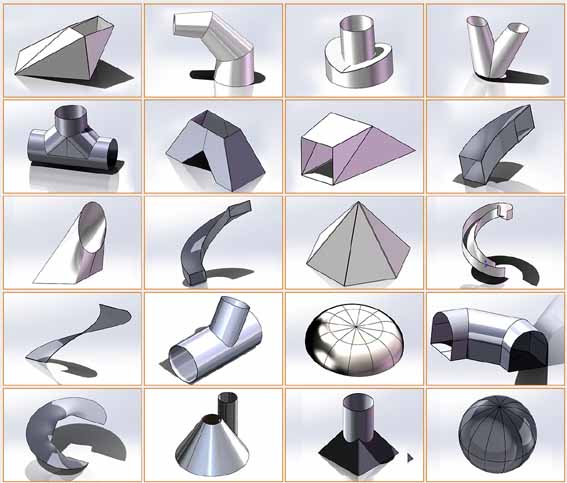

The modern production of sheet metal parts is carried out with the help of technologically advanced machines, the work of which is computer-controlled. This makes it possible to give the workpieces the desired, strictly defined shape, size, texture and other functional properties, which means the possibility of creating an end product that is perfectly tailored to the specific requirements. Modern machines also make it possible to realize the most complicated and complex sheet metal elements in terms of shape and construction.Many different sheet metal processing methods are used in the manufacture of sheet metal parts. One of the most popular is cutting, which allows a variety of strictly defined shapes to be obtained. Sheets can be cut using various techniques and machines. One of the most effective and at the same time oldest methods is oxygen cutting using torches. Oxygen cutting is ideal for machining thick sheet metal. Thinner sheets are usually cut with laser technology and punching technology. A less common method is plasma arc or water cutting, which is carried out with the help of appropriately programmed machines.

Other sheet metal working methods used in the manufacture of sheet metal parts

The most common method of sheet metal processing in recent years is laser cutting. The use of this technology for cutting sheet metal makes it possible to obtain any shape, even the most complex, and perfectly repeatable dimensions, which is impossible to achieve with manual methods. The laser cutting of sheet metal, however, requires appropriate programs and the supervision of an experienced CNC operator who watches over the correct course of the entire process.Another form of sheet metal processing is guillotine cutting. This traditional and fairly simple method is used for simple material cuts where the process and product do not require any particular precision. Cutting with the guillotine is not as precise as other, more modern sheet metal cutting methods. Its use is only economical if large quantities and simplified forms are produced. However, it will not be suitable for the production of small parts that have to be cut more precisely.

The manufacture of sheet metal parts not only includes cutting the material itself, but also bending on press brakes, joining sheet metal and surface treatments such as powder coating and wet painting. The following processes are used to join sheet metal: welding, spot welding, soldering, toxening, riveting, screwing, etc. The most popular of these are spot welding and welding. Spot welding enables two or more sheet metal parts to be connected to one another using electricity and pressure.

When welding sheet metal, in turn, the metal is subjected to a heat treatment using electricity and melted at the edges where the material is joined without applying pressure. The welding can either be carried out manually or with computer-controlled machines or robots. Laser welding is also used for welding purposes, which enables a very aesthetic and strong weld seam that no longer needs to be decolorized.

Welded sheets are usually subjected to a surface treatment such as painting, galvanizing, anodizing or similar and can be used as finished products or semi-parts that are then assembled to other machines and systems.

In the KANGDING design environment, sheet metal parts can be viewed as folded models or as flat patterns. Sheet metal commands allow you to unfold features, work with the model in a flattened state, and then collapse features.

Create sheet metal parts

Sheet metal parts are created from template files. The sheet metal template file incorporates a set of rules. The rules determine some common attributes such as the type and thickness of the material, the unfolding rules, the sizes of the gaps, and so on. You can change the material of a part from sheet aluminum to stainless steel by modifying a single ruler. A material change often leads to changes in the attributes that define the folds and corners. Often these changes involve modifications to the shop machinery and the configurations used to make the parts.Like other parts created in KANGDING, sheet metal parts start with a base feature. Typically, the base feature of a sheet metal part is a single face with a particular shape to which other features (often tabs) are added. A complex design can use a contour flange or contour curve as the initial base feature. Some parts may use a lofted flange as an initial feature.

Unlike regular parts, sheet metal parts are always created from a flat sheet of uniform thickness. This sheet is molded to create the final piece using various manufacturing techniques. In the sheet metal environment, you can create a folded model and unfold it to generate a flat pattern. Developments are often used to describe manufacturing details. Sheet metal commands used to work with flat patterns can provide critical information for fabrication.