Conventional stamping Parts Material Analysis --Nickel Silver Alloy, Phosphor bronze, Beryllium Copper

1. (Nickel Copper Alloy) Nickel Silver Alloy

Nickel Silver Alloy: Refers to the general term for the alloy consisting of 50-70% copper and 15~35% nickel. Its material has excellent toughness, and its bright silver color and stability are suitable for eyeglass frames, tokens, advanced materials and electrical materials.

Reference price: 350NT$/Kg--0.2T, 280NT$/Kg--0.3/0.4T, 190NT$/Kg--0.5 or above

Features: High toughness, high strength, high stability, elasticity, silver white

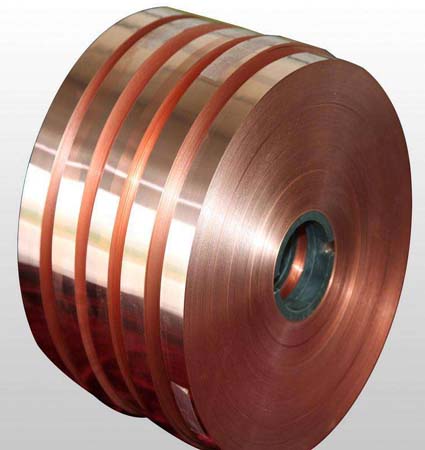

2. Phosphor Bronze Sheet (PBS) PHOSPHOR BRONZE SPRING:

Phosphor bronze is composed of a bronze (copper-tin alloy) deoxidizer, a phosphorus (P) content of 0.03 to 0.35%, and other trace elements such as Fe, Zn, and the like.

Both ductility and fatigue resistance are good.

It can be used for electrical and mechanical materials, and its corrosion resistance and material reliability are higher than those of ordinary copper alloy products. It is made by continuous melting casting (sheet and copper coil) with high material uniformity.

Good conductivity, high elasticity and wear resistance;

It is a shrapnel and conductive material for electrical switches, terminals, etc., but it does not have the strength of stainless steel.

The appearance must be plated. Therefore, the current demand for EMI in Notebook. Reference price: 195NT$/Kg --0.1T.

C5111: Tin content 4%, good strength, good corrosion resistance, excellent processability, can be used for high-performance electrical precision materials.

C5102: With a tin content of 5%, good strength, good corrosion resistance and excellent processability, it can be used for high-performance electrical precision materials.

C5191: Tin content 6%, motor material, followed by terminals, IC components, etc. can be used, high strength and hardness characteristics.

C5212: Tin content 8%, good strength properties for electrical materials.

C5210: Tin content 8%, good fatigue and elastic properties, ideal for high performance electronic connections

3. Bronze sheet (BECU) BERYLLIUM CU:

Highly conductive and highly elastic, it is the best hardness and strength of all copper alloys; It is most suitable for high temperature, high current switching parts. Belongs to hardwood. It is a commonly used material for micro-switches, various advanced terminals, relays and other precision shrapnel. The characteristics are similar to those of PBS, but after heat treatment, it can obtain better hardness and elasticity, and the appearance must be electroplated, but the cost is high. Therefore, it has been used as little as possible in Notebook, but it is difficult to avoid the need for EMI.

Reference Price: 1405NT$/Kg --0.1T, 1105NT$/Kg --0.15T

C17000 Composition: beryllium 1.60 – 1.79 % Cobalt + Nickel 0.20 % Lowest Cobalt + Nickel + Iron 0.6% Maximum Copper Balance, This is a high strength alloy

C17200 Composition: beryllium 1.80 – 2.0 % Cobalt + Nickel 0.20 % Lowest Cobalt + Nickel + Iron 0.6% Maximum copper balance, this is high strength alloy

C17300 Composition: beryllium 1.80 – 2.0 % Cobalt + Nickel 0.20 % Lowest Cobalt + Nickel + Iron 0.6% Highest Lead 0.2 – 0.6 % Copper Balance, This is a high strength alloy

C17510 Ingredients: beryllium 0.2 – 0.6 % nickel 1.4 – 2.2 % copper balance, This is a high-conductivity alloy with a yield strength of 98kg/mm2 and a conductivity and thermal conductivity of 40-60% of pure copper.

C17500 Ingredients: beryllium 0.4 – 0.7 % cobalt 2.4 – 2.7 % copper balance, this is a high-conductivity alloy with a yield strength of 98kg/mm2, and its conductivity and thermal conductivity are 40 – 60% of pure copper.

C17410 Ingredients: beryllium 0.15 – 0.50 % cobalt 0.35– 0.60 % copper balance

This is a high-conductivity alloy with a yield strength of 98kg/mm2 and a conductivity and thermal conductivity of 40 – 60 for pure copper.

275C : This is beryllium copper for casting.