When Cutting Stainless Steel, How do We Choose the Chip Breaking Groove and the Cutting Edge Form?

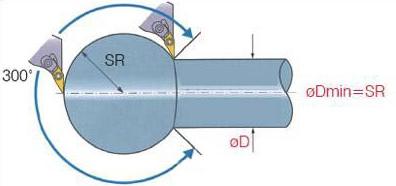

When cutting stainless steel, the appropriate chip breaking groove (roll) should be selected to control continuous chip. Usually, the whole arc or straight arc chip breaking groove (roll) should be used. The width of the chip breaker is Bn = 3 ~ 5 mm, the groove depth h = 0.5 ~ 1.3 mm, and Rn = 2 ~ 8 mm. Under normal circumstances, the ap and f are large when roughing, and the chipbreaking groove should be wide and shallow; When Fine turning, ap and f are small and should be narrower and deeper.

During the cutting process, if the phenomenon of chip winding on the workpiece or the tool occurs, it means that the broken (roll) chip groove is too wide and too shallow, and the feed amount can be increased to break the chip; If the chips are squeezed in the groove, a squeaking sound is heard, or the chip is splashed and hurts, indicating that the chipbreaker is too narrow and too deep, and the feed rate can be reduced. Also pay attention to the position of the control (roll) chipbreaker. The size of the chip breaker is shown in Table 1, Table 2 and Table 3.

| Table 1 External turning tool (roll) chip breaker size | ||||

|

Workpiece diameter (mm) |

Radius Rn (mm) |

Width Bn (mm) |

Front angle g0 (°) |

Chamfer dimension bg (mm) |

| ≤20 | 1.5 | 2 | 42 |

Fine turning:0.05~0.10 Rough turning:0.10~0.20 |

| 2.5 | 3 | 37 | ||

| 20~40 | 3 | 3 | 30 | |

| 3.5 | 3.5 | 30 | ||

| 4 | 4 | 30 | ||

| >40~80 | 4 | 4 | 30 | |

| 4.5 | 4.5 | 30 | ||

| 5 | 5 | 30 | ||

| >80~200 | 5.5 | 5 | 27 |

Fine turning:0.10~0.20 Rough turning:0.15~0.30 |

| 6 | 5.5 | 27 | ||

| 6.5 | 6 | 27.5 | ||

| >200 | 6.5 | 6 | 27.5 | |

| 7 | 6.5 | 27.5 | ||

| 7.5 | 7 | 27.5 | ||

| Table 2 Size of chip breaker (volume) for boring cutter | |||||

|

Boring diameter (mm) |

Radius Rn (mm) |

Processing 1Cr18Ni9Ti austenitic stainless steel and medium hardness 2Cr13 martensitic stainless steel | Processing of concentrated nitric acid stainless steel and harder martensitic stainless steel such as 2Cr13, 3Cr13 | ||

| Width Bn (mm) | Front angle g0 (°) | Width Bn (mm) | Front angle g0 (°) | ||

| ≤20 | 1.6 | 2.0 | 39 | 1.6 | 30 |

| 2.0 | 2.5 | 39 | 2.0 | 30 | |

| 2.5 | 3.0 | 37 | 2.5 | 30 | |

| >20~40 | 2.0 | 2.5 | 39 | 2.0 | 30 |

| 2.5 | 3.0 | 37 | 2.5 | 30 | |

| 3.0 | 3.5 | 36 | 2.8 | 28 | |

| >40~60 | 4.0 | 4.0 | 30 | 3.2 | 24 |

| 4.5 | 4.5 | 30 | 3.5 | 23 | |

| 5.0 | 5.0 | 30 | 4.0 | 24 | |

| >60~80 | 4.5 | 4.5 | 30 | 3.5 | 23 |

| 5.0 | 5.0 | 30 | 4.0 | 24 | |

| 6.0 | 6.0 | 30 | 5.0 | 24.5 | |

| >80 | 5.0 | 4.0 | 24 | 3.5 | 20.5 |

| 6.0 | 5.0 | 24.5 | 4.5 | 22 | |

| 7 | 6.0 | 25.5 | 5.0 | 21 | |

| Table 3 Cutting knife chip breaker (roll) size | ||||||||||||

| Cutting diameter (mm) | ≤20 | >20~50 | >50~80 | >80~120 | ||||||||

| Radius Rn (mm) | 2.5 | 3.2 | 4.2 | 3.2 | 4.5 | 5.5 | 4.2 | 5.5 | 6.5 | 5.5 | 6.5 | 8 |

| Width Bn (mm) | 3 | 4 | 5 | 4 | 5 | 6 | 5 | 6 | 7 | 6 | 7 | 8 |

| Front angle g0 (°) | 37 | 39 | 36.5 | 39 | 30.5 | 33 | 36.5 | 33 | 32.5 | 33 | 32.5 | 30 |