What is Sheet Metal?

Sheet metal, a metal product processing technology, has so far had no more complete definition of sheet metal.

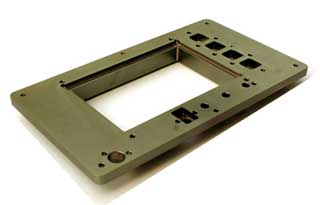

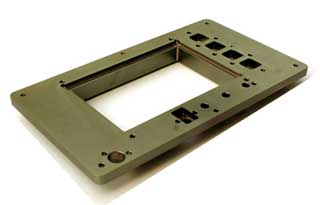

According to a definition on a foreign professional journal, it can be defined as: Sheet metal is a comprehensive cold processing technology for thin metal sheets (usually below 8mm). including shear, punch/cut/composite, folding, riveting, splicing, and forming (eg, automotive bodywork). Its distinguishing feature is the uniform thickness of the same part.

Process characteristics

Sheet metal has the characteristics of light weight, high strength, electrical conductivity (can be used for electromagnetic shielding), low cost, and large-scale mass production performance. It has been widely used in electronic appliances, communications, automobile industry, medical equipment and other fields. For example, in the computer case, mobile phone and MP3, sheet metal is an indispensable part. With the increasing use of sheet metal, the design of sheet metal parts has become an important part of the product development process. Mechanical engineers must be proficient in the design skills of sheet metal parts, so that the design of sheet metal not only meets the requirements of the product's functions and appearance, but also makes the stamping molds simple to manufacture and low in cost.

Main material

There are many sheet metal materials suitable for stamping processing. Sheet metal materials widely used in the electrical and electronic industry include:

1. Ordinary cold rolled sheet SPCC:

SPCC refers to the continuous rolling of steel ingots into a coil or sheet material of a desired thickness through a cold rolling mill. SPCC surface without any protection, exposed to the air can easily be oxidized, especially in the humid environment, the oxidation speed, the emergence of dark red rust, In use, the surface should be painted, plated or otherwise protected.

2. Galvanized steel plate SECC:

SECC substrates as a general cold rolled steel coil, After the continuous electrogalvanized production line is degreased, pickled, electroplated and various post-treatment processes, it becomes an electro-galvanized product. SECC not only has the mechanical properties and similar processability of ordinary cold rolled steel sheets, but also has superior corrosion resistance and decorative appearance. In the electronic products, home appliances and furniture market has great competitiveness and replaceability. For example, the computer chassis is commonly used SECC.

3. Hot dip galvanized steel sheet SGCC:

Hot-dip galvanized steel coil refers to semi-finished products after hot-rolled pickling or cold rolling. After cleaning, annealing, immersed in a molten zinc bath at a temperature of about 460°C, the steel sheet is plated with a zinc layer. After conditioning, leveling and chemical treatment. SGCC material is harder than SECC material, poor in ductility (to avoid deep drawing design), thicker zinc layer, and poor weldability.

4. Stainless steel SUS301:

Cr (chromium) content is lower than SUS304, and its corrosion resistance is poor. However, after cold working, good tensile strength and hardness can be obtained, and the elasticity is better. Used for shrapnel, springs and EMI.

5. Stainless steel SUS304:

One of the most widely used stainless steels, Because it contains Ni (nickel), it is richer in corrosion resistance and heat resistance than steel containing Cr (chromium). Has very good mechanical properties, no heat treatment hardening, no elasticity.

Sheet metal technology

The basic equipment for sheet metal processing generally includes Shear Machine, CNC Punching Machine, Laser, Plasma, Cutting Machine, Bending Machine, Drilling Machine, and various auxiliary equipment such as: Uncoiler, Leveler, Deburrer, Spot Welder, etc.

In general, the four most important steps in the sheet metal process are shearing, punching/cutting, folding/rolling, welding, and surface treatment. Sheet metal, the word comes from the English platemetal, Generally, some metal sheets are plastically deformed by hand or die stamping to form the desired shape and size. It can further form more complex parts by welding or a small amount of mechanical processing. For example, the chimneys, tin furnaces, and car shells commonly used in homes are sheet metal parts.

Sheet metal processing:

Specifically, for example, chimneys, iron drums, fuel tank oil cans, ventilation ducts, A big bent head, hemispherical domes, funnels, and the like are manufactured using sheet metal. The main processes are shearing, bending, buttoning, welding, riveting, and the like.Need some knowledge of geometry.

Sheet metal is sheet metal member, i.e. by stamping, bending, stretching and other means of processing components, a general definition is: Parts with constant thickness during processing. Corresponding to the castings, forgings, machining parts, etc. For example, the outer shell of a car is a sheet metal piece, and some kitchen utensils made of stainless steel are also sheet metal parts.

Modern sheet metal crafts include:

It is filament power supply winding, laser cutting, heavy processing, metal bonding, metal drawing, plasma cutting, precision welding, roll forming, sheet metal bending forming, die forging, water jet cutting, precision welding, etc.

The surface treatment of sheet metal parts is also a very important part of sheet metal processing because it has the effect of preventing parts from rusting and beautifying the appearance of the product. The surface pretreatment of sheet metal parts is mainly used to remove oil, scale, rust, etc. It prepares for surface post-treatment, and the post-treatment is mainly spray (baking) paint, sprayed plastic and rust-proof plating.

3D software, SolidWorks, UG, Pro/E, SolidEdge, TopSolid, and CATIA all have a design function for sheet metal parts.

Mainly through the editing of 3D graphics to get the data required for sheet metal processing (such as unfolding, bending lines, etc.) as well as CNC Punching Machine, Laser, Plasma, Water Jet Cutting Machine, Combination Machine and CNC Bending Machine. etc., to provide data.

Technological Design

In meeting the requirements of the product's function, appearance, etc., the design of sheet metal should ensure that the stamping process is simple, the stamping mold is easy to make, the sheet metal stamping quality is high, and the dimension is stable.

The detailed sheet metal design guide can refer to the “Part Structure Design Processability” and “Product Design Guide for Manufacturing and Assembly” published by Machinery Industry Press.

Process

After receiving customer drawings, different blanking methods are selected according to different plans and batch sizes, including laser, CNC punch press, shear plate, and die, etc., and then correspondingly developed according to the drawings. CNC punching machine is affected by the tool, for some special-shaped workpieces and irregular hole processing, there will be large burrs on the edge, to be deburring later, at the same time have a certain impact on the accuracy of the workpiece; The laser processing has no tool limitation and the section is flat, which is suitable for the processing of special-shaped workpieces, but it takes a long time to process small workpieces. Place the worktable next to the CNC and the laser, which facilitates the placement of the sheet material on the machine for processing and reduces the workload of the lift plate.

Some of the edge materials that can be used are placed in the designated place to provide material for the trial mold during bending. After blanking the workpiece, edge angle, burrs, the contact necessary to finishing (sanding), At the tool joints, trimming is done with a flat boring tool, and for burr larger workpieces, trimming is done with a grinding machine. The small inner hole joint is trimmed with a corresponding small file to ensure the appearance of the appearance, At the same time, the trimming of the outer shape also ensures the positioning during bending, so that the work piece is located on the bending machine at the same time during bending. Guarantee the same size of the same batch of products.

After the blanking is completed, the next process is entered, and different workpieces enter the corresponding process according to the processing requirements.There are bending, riveting, clamming and tapping, spot welding, bulging, step difference, and sometimes the nuts or studs are pressed after one or two bends. Among them, the place where the mold is used for bulging and step difference should be considered to be processed first, so as to avoid interference after other processes are processed first, and the required processing cannot be completed. When there is a hook on the upper cover or the lower shell, if it cannot be welded after bending, it must be processed before bending.

When bending, it is necessary to first determine the tool and sipe for bending according to the size on the drawing and the material thickness. Avoiding the collision of the product with the tool and causing deformation is the key to the selection of the upper die (in the same product, different types of upper die may be used). The choice of lower die is determined by the thickness of the sheet. The second step is to determine the sequence of the bending. The general law of bending is first inside/outside, first small | after large, first special | after ordinary. The workpiece that has to press the dead edge first bends the workpiece to 30°-40°, and then uses the leveling die to crush the workpiece.

When riveting, it is necessary to consider the height of the stud and choose the same die, and then adjust the pressure of the press to ensure that the stud and the workpiece surface are flush. Avoid the stud not firmly pressed or pressed out, exceeding the workpiece surface, resulting in scrapped parts.

There are welding argon arc welding, spot welding, carbon dioxide welding, manual arc welding, spot welding must first consider the location of the workpiece welding, in batch production, consider the positioning fixture to ensure accurate spot welding.

In order to weld firmly, hitting the bumps on the workpiece to be welded can make the bumps evenly contact with the flat plate before electrified welding, so as to ensure consistent heating at each point, and at the same time, the welding position can also be determined. Similarly, welding is required. To adjust the pre-press time, pressure holding time, maintenance time, and stop time, ensure that the workpiece can be spot welded firmly. After spot welding, there will be a welding scar on the surface of the workpiece. It is to be treated with a flat mill. Argon arc welding is mainly used when two workpieces are large and they are connected together. Or a corner of the workpiece processing, to achieve smooth workpiece surface is smooth. The heat generated during argon-arc welding tends to deform the workpiece. After welding, it is necessary to use a grinder and a flat mill for processing, especially in terms of corners.

Surface Treatment

Workpieces must be surface treated after bending, riveting, etc., and the surface treatment of different boards is different.

After the cold plate is processed, the surface plating is generally performed. After the plating, no spraying treatment is performed. The phosphating treatment is adopted and the spraying treatment is performed after the phosphating treatment.

Plating plate surface cleaning, degreasing, and then spraying.

Stainless steel plate (mirror panel, fog panel, wire drawing board) can be wire-drawing processing before bending, no spraying, if you need to spray hair processing;

The aluminum plate is generally oxidized, and different oxidation background colors are selected according to the different colors of spraying. Commonly used black and natural oxidation; The aluminum plate should be sprayed after chromate oxidation treatment. The pre-treatment of the surface can make the surface clean, significantly improve the adhesion of the coating film, and can double the corrosion resistance of the coating film.

Cleaning

The cleaning process first cleans the workpiece, first hangs the workpiece on the assembly line, first passes through the cleaning solution (alloy oil removal powder), and then enters clean water.

After passing through the spray zone, it passes through the drying zone and finally removes the workpiece from the line.

After surface treatment, enter the spraying process, When the work piece is required to be sprayed after assembly, the tooth or part of the conductive hole needs to be protected. The tooth hole can be inserted into a soft glue stick or a screw, and the conductive protection needs to be affixed with a high temperature tape. Large quantities of positioning fixtures are used to position and protect, so that it will not be sprayed into the workpiece during spraying. The nut (flange) hole visible on the outer surface of the workpiece is protected with a screw to prevent the need for a return tooth at the hole of the workpiece nut (flange) after painting.

Some large batches of workpieces also use tooling protection; When the workpiece is not sprayed, the areas that do not need to be sprayed are covered with high-temperature resistant tape and paper. Some nuts (studs) holes that are exposed to the outside are protected by screws or high temperature resistant rubber. If the workpiece is painted on both sides, use the same method to protect the hole of the nut (stud); Small workpieces are strung together using lead wire or paper clips and then sprayed; Some workpiece surface requirements are high, and Ash scraping treatment is required before spraying; Some workpieces are protected with a special high temperature sticker at the ground symbol. When spraying, the workpiece is first hung on the line, and the dust on the surface is blown off by the trachea. Into the spray area spraying, sprayed along the line into the drying area, and finally remove the sprayed workpiece from the assembly line. There are two types of manual spraying and automatic spraying, so the tooling used is different.

After the spraying, it enters the assembly process. Before the assembly, the protection sticker used in the original coating shall be torn off, and the threaded hole in the part shall not be scattered with paint or powder. Throughout the process, to wear gloves to avoid dust attached to the work hand, some of the work but also blown clean with air gun. After assembly, it enters the packaging process. After the inspection of the workpiece, it is put into a special packaging bag for protection. Some parts without special packaging are packaged with bubble film, etc. First bubble film package before the package can be cut to the size of the workpiece, so as not to cut the side face packaging, processing speed impact; Large quantities can be customized special carton or bubble bags, pads, trays, wooden boxes and so on. Packed into a carton and then affixed to the cartons the corresponding finished or semi-finished product labels.

In addition to the stringent requirements in the production process, the quality of sheet metal parts requires independent quality inspection of production.

First, strictly control the dimensions according to the drawings. The second is to strictly control the appearance quality, and to repair or dispose of the inconsistent dimensions.

Appearance not allowed to touch, scratch, after spraying color, corrosion resistance, adhesion, etc. for testing. In this way, you can find unfolding errors, bad habits in the process, errors in the process, Such as several programming errors, mold errors, etc.

According to a definition on a foreign professional journal, it can be defined as: Sheet metal is a comprehensive cold processing technology for thin metal sheets (usually below 8mm). including shear, punch/cut/composite, folding, riveting, splicing, and forming (eg, automotive bodywork). Its distinguishing feature is the uniform thickness of the same part.

Process characteristics

Sheet metal has the characteristics of light weight, high strength, electrical conductivity (can be used for electromagnetic shielding), low cost, and large-scale mass production performance. It has been widely used in electronic appliances, communications, automobile industry, medical equipment and other fields. For example, in the computer case, mobile phone and MP3, sheet metal is an indispensable part. With the increasing use of sheet metal, the design of sheet metal parts has become an important part of the product development process. Mechanical engineers must be proficient in the design skills of sheet metal parts, so that the design of sheet metal not only meets the requirements of the product's functions and appearance, but also makes the stamping molds simple to manufacture and low in cost.

Main material

There are many sheet metal materials suitable for stamping processing. Sheet metal materials widely used in the electrical and electronic industry include:

1. Ordinary cold rolled sheet SPCC:

SPCC refers to the continuous rolling of steel ingots into a coil or sheet material of a desired thickness through a cold rolling mill. SPCC surface without any protection, exposed to the air can easily be oxidized, especially in the humid environment, the oxidation speed, the emergence of dark red rust, In use, the surface should be painted, plated or otherwise protected.

2. Galvanized steel plate SECC:

SECC substrates as a general cold rolled steel coil, After the continuous electrogalvanized production line is degreased, pickled, electroplated and various post-treatment processes, it becomes an electro-galvanized product. SECC not only has the mechanical properties and similar processability of ordinary cold rolled steel sheets, but also has superior corrosion resistance and decorative appearance. In the electronic products, home appliances and furniture market has great competitiveness and replaceability. For example, the computer chassis is commonly used SECC.

3. Hot dip galvanized steel sheet SGCC:

Hot-dip galvanized steel coil refers to semi-finished products after hot-rolled pickling or cold rolling. After cleaning, annealing, immersed in a molten zinc bath at a temperature of about 460°C, the steel sheet is plated with a zinc layer. After conditioning, leveling and chemical treatment. SGCC material is harder than SECC material, poor in ductility (to avoid deep drawing design), thicker zinc layer, and poor weldability.

4. Stainless steel SUS301:

Cr (chromium) content is lower than SUS304, and its corrosion resistance is poor. However, after cold working, good tensile strength and hardness can be obtained, and the elasticity is better. Used for shrapnel, springs and EMI.

5. Stainless steel SUS304:

One of the most widely used stainless steels, Because it contains Ni (nickel), it is richer in corrosion resistance and heat resistance than steel containing Cr (chromium). Has very good mechanical properties, no heat treatment hardening, no elasticity.

Sheet metal technology

The basic equipment for sheet metal processing generally includes Shear Machine, CNC Punching Machine, Laser, Plasma, Cutting Machine, Bending Machine, Drilling Machine, and various auxiliary equipment such as: Uncoiler, Leveler, Deburrer, Spot Welder, etc.

In general, the four most important steps in the sheet metal process are shearing, punching/cutting, folding/rolling, welding, and surface treatment. Sheet metal, the word comes from the English platemetal, Generally, some metal sheets are plastically deformed by hand or die stamping to form the desired shape and size. It can further form more complex parts by welding or a small amount of mechanical processing. For example, the chimneys, tin furnaces, and car shells commonly used in homes are sheet metal parts.

Sheet metal processing:

Specifically, for example, chimneys, iron drums, fuel tank oil cans, ventilation ducts, A big bent head, hemispherical domes, funnels, and the like are manufactured using sheet metal. The main processes are shearing, bending, buttoning, welding, riveting, and the like.Need some knowledge of geometry.

Sheet metal is sheet metal member, i.e. by stamping, bending, stretching and other means of processing components, a general definition is: Parts with constant thickness during processing. Corresponding to the castings, forgings, machining parts, etc. For example, the outer shell of a car is a sheet metal piece, and some kitchen utensils made of stainless steel are also sheet metal parts.

Modern sheet metal crafts include:

It is filament power supply winding, laser cutting, heavy processing, metal bonding, metal drawing, plasma cutting, precision welding, roll forming, sheet metal bending forming, die forging, water jet cutting, precision welding, etc.

The surface treatment of sheet metal parts is also a very important part of sheet metal processing because it has the effect of preventing parts from rusting and beautifying the appearance of the product. The surface pretreatment of sheet metal parts is mainly used to remove oil, scale, rust, etc. It prepares for surface post-treatment, and the post-treatment is mainly spray (baking) paint, sprayed plastic and rust-proof plating.

3D software, SolidWorks, UG, Pro/E, SolidEdge, TopSolid, and CATIA all have a design function for sheet metal parts.

Mainly through the editing of 3D graphics to get the data required for sheet metal processing (such as unfolding, bending lines, etc.) as well as CNC Punching Machine, Laser, Plasma, Water Jet Cutting Machine, Combination Machine and CNC Bending Machine. etc., to provide data.

Technological Design

In meeting the requirements of the product's function, appearance, etc., the design of sheet metal should ensure that the stamping process is simple, the stamping mold is easy to make, the sheet metal stamping quality is high, and the dimension is stable.

The detailed sheet metal design guide can refer to the “Part Structure Design Processability” and “Product Design Guide for Manufacturing and Assembly” published by Machinery Industry Press.

Process

After receiving customer drawings, different blanking methods are selected according to different plans and batch sizes, including laser, CNC punch press, shear plate, and die, etc., and then correspondingly developed according to the drawings. CNC punching machine is affected by the tool, for some special-shaped workpieces and irregular hole processing, there will be large burrs on the edge, to be deburring later, at the same time have a certain impact on the accuracy of the workpiece; The laser processing has no tool limitation and the section is flat, which is suitable for the processing of special-shaped workpieces, but it takes a long time to process small workpieces. Place the worktable next to the CNC and the laser, which facilitates the placement of the sheet material on the machine for processing and reduces the workload of the lift plate.

Some of the edge materials that can be used are placed in the designated place to provide material for the trial mold during bending. After blanking the workpiece, edge angle, burrs, the contact necessary to finishing (sanding), At the tool joints, trimming is done with a flat boring tool, and for burr larger workpieces, trimming is done with a grinding machine. The small inner hole joint is trimmed with a corresponding small file to ensure the appearance of the appearance, At the same time, the trimming of the outer shape also ensures the positioning during bending, so that the work piece is located on the bending machine at the same time during bending. Guarantee the same size of the same batch of products.

After the blanking is completed, the next process is entered, and different workpieces enter the corresponding process according to the processing requirements.There are bending, riveting, clamming and tapping, spot welding, bulging, step difference, and sometimes the nuts or studs are pressed after one or two bends. Among them, the place where the mold is used for bulging and step difference should be considered to be processed first, so as to avoid interference after other processes are processed first, and the required processing cannot be completed. When there is a hook on the upper cover or the lower shell, if it cannot be welded after bending, it must be processed before bending.

When bending, it is necessary to first determine the tool and sipe for bending according to the size on the drawing and the material thickness. Avoiding the collision of the product with the tool and causing deformation is the key to the selection of the upper die (in the same product, different types of upper die may be used). The choice of lower die is determined by the thickness of the sheet. The second step is to determine the sequence of the bending. The general law of bending is first inside/outside, first small | after large, first special | after ordinary. The workpiece that has to press the dead edge first bends the workpiece to 30°-40°, and then uses the leveling die to crush the workpiece.

When riveting, it is necessary to consider the height of the stud and choose the same die, and then adjust the pressure of the press to ensure that the stud and the workpiece surface are flush. Avoid the stud not firmly pressed or pressed out, exceeding the workpiece surface, resulting in scrapped parts.

There are welding argon arc welding, spot welding, carbon dioxide welding, manual arc welding, spot welding must first consider the location of the workpiece welding, in batch production, consider the positioning fixture to ensure accurate spot welding.

In order to weld firmly, hitting the bumps on the workpiece to be welded can make the bumps evenly contact with the flat plate before electrified welding, so as to ensure consistent heating at each point, and at the same time, the welding position can also be determined. Similarly, welding is required. To adjust the pre-press time, pressure holding time, maintenance time, and stop time, ensure that the workpiece can be spot welded firmly. After spot welding, there will be a welding scar on the surface of the workpiece. It is to be treated with a flat mill. Argon arc welding is mainly used when two workpieces are large and they are connected together. Or a corner of the workpiece processing, to achieve smooth workpiece surface is smooth. The heat generated during argon-arc welding tends to deform the workpiece. After welding, it is necessary to use a grinder and a flat mill for processing, especially in terms of corners.

Surface Treatment

Workpieces must be surface treated after bending, riveting, etc., and the surface treatment of different boards is different.

After the cold plate is processed, the surface plating is generally performed. After the plating, no spraying treatment is performed. The phosphating treatment is adopted and the spraying treatment is performed after the phosphating treatment.

Plating plate surface cleaning, degreasing, and then spraying.

Stainless steel plate (mirror panel, fog panel, wire drawing board) can be wire-drawing processing before bending, no spraying, if you need to spray hair processing;

The aluminum plate is generally oxidized, and different oxidation background colors are selected according to the different colors of spraying. Commonly used black and natural oxidation; The aluminum plate should be sprayed after chromate oxidation treatment. The pre-treatment of the surface can make the surface clean, significantly improve the adhesion of the coating film, and can double the corrosion resistance of the coating film.

Cleaning

The cleaning process first cleans the workpiece, first hangs the workpiece on the assembly line, first passes through the cleaning solution (alloy oil removal powder), and then enters clean water.

After passing through the spray zone, it passes through the drying zone and finally removes the workpiece from the line.

After surface treatment, enter the spraying process, When the work piece is required to be sprayed after assembly, the tooth or part of the conductive hole needs to be protected. The tooth hole can be inserted into a soft glue stick or a screw, and the conductive protection needs to be affixed with a high temperature tape. Large quantities of positioning fixtures are used to position and protect, so that it will not be sprayed into the workpiece during spraying. The nut (flange) hole visible on the outer surface of the workpiece is protected with a screw to prevent the need for a return tooth at the hole of the workpiece nut (flange) after painting.

Some large batches of workpieces also use tooling protection; When the workpiece is not sprayed, the areas that do not need to be sprayed are covered with high-temperature resistant tape and paper. Some nuts (studs) holes that are exposed to the outside are protected by screws or high temperature resistant rubber. If the workpiece is painted on both sides, use the same method to protect the hole of the nut (stud); Small workpieces are strung together using lead wire or paper clips and then sprayed; Some workpiece surface requirements are high, and Ash scraping treatment is required before spraying; Some workpieces are protected with a special high temperature sticker at the ground symbol. When spraying, the workpiece is first hung on the line, and the dust on the surface is blown off by the trachea. Into the spray area spraying, sprayed along the line into the drying area, and finally remove the sprayed workpiece from the assembly line. There are two types of manual spraying and automatic spraying, so the tooling used is different.

After the spraying, it enters the assembly process. Before the assembly, the protection sticker used in the original coating shall be torn off, and the threaded hole in the part shall not be scattered with paint or powder. Throughout the process, to wear gloves to avoid dust attached to the work hand, some of the work but also blown clean with air gun. After assembly, it enters the packaging process. After the inspection of the workpiece, it is put into a special packaging bag for protection. Some parts without special packaging are packaged with bubble film, etc. First bubble film package before the package can be cut to the size of the workpiece, so as not to cut the side face packaging, processing speed impact; Large quantities can be customized special carton or bubble bags, pads, trays, wooden boxes and so on. Packed into a carton and then affixed to the cartons the corresponding finished or semi-finished product labels.

In addition to the stringent requirements in the production process, the quality of sheet metal parts requires independent quality inspection of production.

First, strictly control the dimensions according to the drawings. The second is to strictly control the appearance quality, and to repair or dispose of the inconsistent dimensions.

Appearance not allowed to touch, scratch, after spraying color, corrosion resistance, adhesion, etc. for testing. In this way, you can find unfolding errors, bad habits in the process, errors in the process, Such as several programming errors, mold errors, etc.