Turning and milling combined machining impeller blades

Impeller blade machining, as a typical part type for five-coordinate machining, has a huge market demand. In fact, most of these parts can be completed in the turning and milling complex machining center. For some turning and milling machines with B-axis linkage, the types of parts that can be machined will be more extensive. This type of equipment not only has the turning function, but also can perform the milling work of three to five coordinate linkage.

With the development of machine tool hardware, the rigidity of the machine tool can be significantly improved, and the rough finishing can be completed in one operation. Moreover, from the technical point of view, the turning and milling composite equipment has the advantages of simple clamping and positioning of parts, various rough processing methods, and convenient chip removal. At the same time, the turning and milling equipment is getting closer and closer in terms of price compared with the multi-axis milling machining center of the same grade. Therefore, the use of turning and milling composite equipment to process impeller blades is gradually becoming a reality.

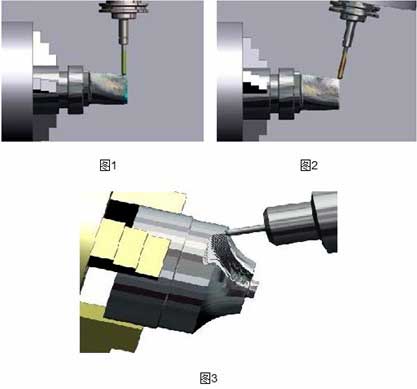

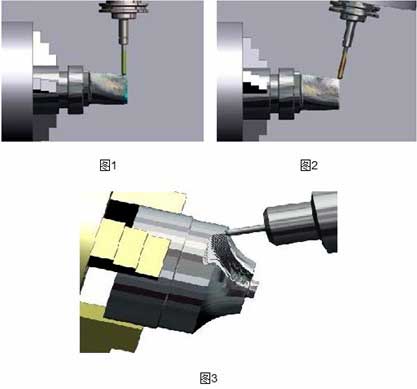

For ordinary C&Y turning and milling equipment, the blade can be processed by C-axis linkage. Such a control system is actually a three-axis control system. Through XZC three-axis linkage to complete the processing of the profile, no need to make more investment in the machine. Just select a CAM software to provide this functionality. as the picture shows:

KangDing provides Japan's Daban MACTURN series of turning-milling CNC machine tools, a new composite turning and milling center for machining centers and turning centers. There are 3 models of MACTURN250, MACTURN350 and MACTURN550. Machinable worms, blades, spirals, cams, eccentrics and bevels. Strong composite precision machining for complex shapes such as airplanes, automobiles, engines, pumps, molds, and tools. Has the following performance characteristics:

With the development of machine tool hardware, the rigidity of the machine tool can be significantly improved, and the rough finishing can be completed in one operation. Moreover, from the technical point of view, the turning and milling composite equipment has the advantages of simple clamping and positioning of parts, various rough processing methods, and convenient chip removal. At the same time, the turning and milling equipment is getting closer and closer in terms of price compared with the multi-axis milling machining center of the same grade. Therefore, the use of turning and milling composite equipment to process impeller blades is gradually becoming a reality.

For ordinary C&Y turning and milling equipment, the blade can be processed by C-axis linkage. Such a control system is actually a three-axis control system. Through XZC three-axis linkage to complete the processing of the profile, no need to make more investment in the machine. Just select a CAM software to provide this functionality. as the picture shows:

KangDing provides Japan's Daban MACTURN series of turning-milling CNC machine tools, a new composite turning and milling center for machining centers and turning centers. There are 3 models of MACTURN250, MACTURN350 and MACTURN550. Machinable worms, blades, spirals, cams, eccentrics and bevels. Strong composite precision machining for complex shapes such as airplanes, automobiles, engines, pumps, molds, and tools. Has the following performance characteristics:

▪ The machine tool has a spindle, a counter spindle and a tool holder for the lathe.

▪ X, Y, Z, B axis and automatic tool changer with machining center,

▪ This machine has nine-axis control for simultaneous high-speed machining of four axes. The X, Y, Z three-axis guide rails are driven by rollers.

▪ Processing capacity can be turned up to:

2.5mm2, milling up to: 68cm3/min, roundness can reach: 0.3μm.

Y-axis travel: ≥160mm.

The ATC tool magazine has a large capacity and the power of the power tool is large. It can be equipped with a lower tool holder with 12 positions.

▪ X, Y, Z, B axis and automatic tool changer with machining center,

▪ This machine has nine-axis control for simultaneous high-speed machining of four axes. The X, Y, Z three-axis guide rails are driven by rollers.

▪ Processing capacity can be turned up to:

2.5mm2, milling up to: 68cm3/min, roundness can reach: 0.3μm.

Y-axis travel: ≥160mm.

The ATC tool magazine has a large capacity and the power of the power tool is large. It can be equipped with a lower tool holder with 12 positions.