Solution for deep hole high precision grinding of broken hammer cylinder

Hydraulic breakers are already an important part of hydraulic excavators. The power source of the hydraulic breaker is the pressure oil supplied by the pump station of the excavator or loader. The hydraulic breaker mainly consists of pistons, main bolts, front parts of the main body, cylinders, and rear parts of the main body.

Hydraulic cylinders are mainly machined by CNC (CNC machine tools) and large grinding machines. Completion of grinding the inner diameter to improve the surface roughness and the degree of completion of the product.

The Japanese NVG-7LH deep-hole grinding vertical CNC grinding machine provided by KangDing can process deep holes of 1000mm. It provides a perfect solution for high-precision grinding of deep holes in the breaker cylinder.

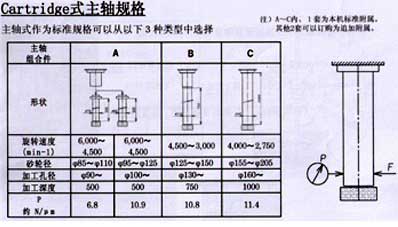

The deep hole grinding vertical CNC grinding machine is equipped with two spindles, one thick spindle and one thin spindle. Grind with a coarse spindle and then with a fine spindle. The inner hole, the outer circle and the end surface of the breaker cylinder can be ground by one clamping, which improves the working efficiency by more than one time.

As the investment in urban infrastructure construction continues to increase. As well as the rapid development of the hydraulic excavator industry, the market demand for hydraulic breakers, which is one of the main working components of hydraulic excavators, has also increased rapidly. The Japanese NVG-7LH deep hole grinding vertical CNC grinding machine can create the greatest benefit for the company in the shortest time.

The Japanese NVG-7LH deep-hole grinding vertical CNC grinding machine provided by KangDing can process deep holes of 1000mm. It provides a perfect solution for high-precision grinding of deep holes in the breaker cylinder.

The deep hole grinding vertical CNC grinding machine is equipped with two spindles, one thick spindle and one thin spindle. Grind with a coarse spindle and then with a fine spindle. The inner hole, the outer circle and the end surface of the breaker cylinder can be ground by one clamping, which improves the working efficiency by more than one time.

As the investment in urban infrastructure construction continues to increase. As well as the rapid development of the hydraulic excavator industry, the market demand for hydraulic breakers, which is one of the main working components of hydraulic excavators, has also increased rapidly. The Japanese NVG-7LH deep hole grinding vertical CNC grinding machine can create the greatest benefit for the company in the shortest time.