The Method of Setting Feed Route for Milling Inner Groove in NC Milling Center

Key words: milling internal groove, feed route

In order to ensure the surface roughness requirement of workpiece contour surface after processing, the final inner cavity contour should be arranged for continuous processing in the last processing.

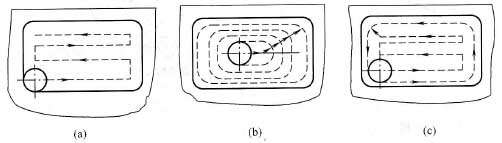

The inner groove refers to a flat bottom groove bounded by a closed curve. All end milling cutters are machined with flat-bottom end milling cutters. The radius of cutter roundness should meet the drawing requirements of inner groove. Fig. 1-16 shows three feeding routes for machining inner grooves. Fig. 1-16 (a) and Fig. 1-16 (b) respectively process inner grooves by line-cutting method and ring-cutting method. The common point of the two feeding routes is that they can cut the whole area of the inner cavity, leave no dead angle, do not damage the contour, and minimize the overlap of repetitive feeding. The difference is that the feed route of the row cutting method is shorter than the loop cutting method, but the row cutting method will leave a residual area between the start point and the end point of each feeding, and the required surface roughness is not obtained; The surface roughness obtained by the ring cutting method is better than the line cutting method, but the ring cutting method needs to expand the contour line outwards one by one, and the calculation of the tool point is slightly more complicated. Use the feed route shown in Figure 1-16(c), that is, first cut the middle part by line cutting, and finally cut the surface of the contour by ring cutting, which can make the total feed route. Shorter, and better surface roughness.

Figure 1-16 Inner groove machining feed route

(a) row cutting method; (b) ring cutting method; (c) row cutting ten ring cutting method

In order to ensure the surface roughness requirement of workpiece contour surface after processing, the final inner cavity contour should be arranged for continuous processing in the last processing.

The inner groove refers to a flat bottom groove bounded by a closed curve. All end milling cutters are machined with flat-bottom end milling cutters. The radius of cutter roundness should meet the drawing requirements of inner groove. Fig. 1-16 shows three feeding routes for machining inner grooves. Fig. 1-16 (a) and Fig. 1-16 (b) respectively process inner grooves by line-cutting method and ring-cutting method. The common point of the two feeding routes is that they can cut the whole area of the inner cavity, leave no dead angle, do not damage the contour, and minimize the overlap of repetitive feeding. The difference is that the feed route of the row cutting method is shorter than the loop cutting method, but the row cutting method will leave a residual area between the start point and the end point of each feeding, and the required surface roughness is not obtained; The surface roughness obtained by the ring cutting method is better than the line cutting method, but the ring cutting method needs to expand the contour line outwards one by one, and the calculation of the tool point is slightly more complicated. Use the feed route shown in Figure 1-16(c), that is, first cut the middle part by line cutting, and finally cut the surface of the contour by ring cutting, which can make the total feed route. Shorter, and better surface roughness.

Figure 1-16 Inner groove machining feed route

(a) row cutting method; (b) ring cutting method; (c) row cutting ten ring cutting method