Structural Composition Of precision CNC Machine Tools

CNC machine tools integrate machine tools, computers, motors and drag, motion control, detection and other technologies into one automation equipment. The basic components of CNC machine tools include control media, numerical control devices, servo systems, feedback devices and machine tools, as shown below:

1, Control Medium

The control medium is a medium for storing all the action tools required for numerical control machining with respect to the workpiece position information, and it records the machining program of the parts. Therefore, the control medium refers to the information carrier that transmits the part processing information to the numerical control device. There are many forms of control media, which vary with the type of numerical control device. Commonly used are perforated tapes, punched cards, magnetic tapes, magnetic disks, and the like. With the development of numerical control technology, punched tape, punch cards become obsolete. The method of using CAD/CAM software in computer programming, and then communicating with the numerical control system through the computer, and transmitting the program and data directly to the numerical control device is more and more widely used.

2, Numerical Control Device

The numerical control device is the core of the numerical control machine tool, and people call it the “central system”. Modern CNC machine tools are used computer numerical control device CNC. The numerical control device includes an input device, a central processing unit (CPU), and an output device, and the like, and the numerical control device can complete information input, storage, conversion, interpolation operation, and realize various control functions.

3, Servo System

The servo system is a drive unit that receives commands from the numerical control device and drives the movement of the machine tool actuator. Including spindle drive unit, feed drive unit, spindle motor and feed motor. When working, the servo system accepts the command information of the CNC system. And according to the requirements of the command information and the position and speed feedback signals, the moving parts of the machine tool or the executing parts are driven. Process parts that meet the requirements of the drawings.

4,Feedback Device

The feedback device consists of a measuring component and a corresponding circuit that detects the velocity and displacement and feeds back the information to form a closed loop control. Some CNC machines with low precision requirements, without feedback devices, are called open loop systems.

5, Machine Body

The machine body is the entity of the CNC machine tool and is the mechanical part that completes the actual cutting process. It includes the bed, the base, the workbench, the saddle, the spindle, and so on.

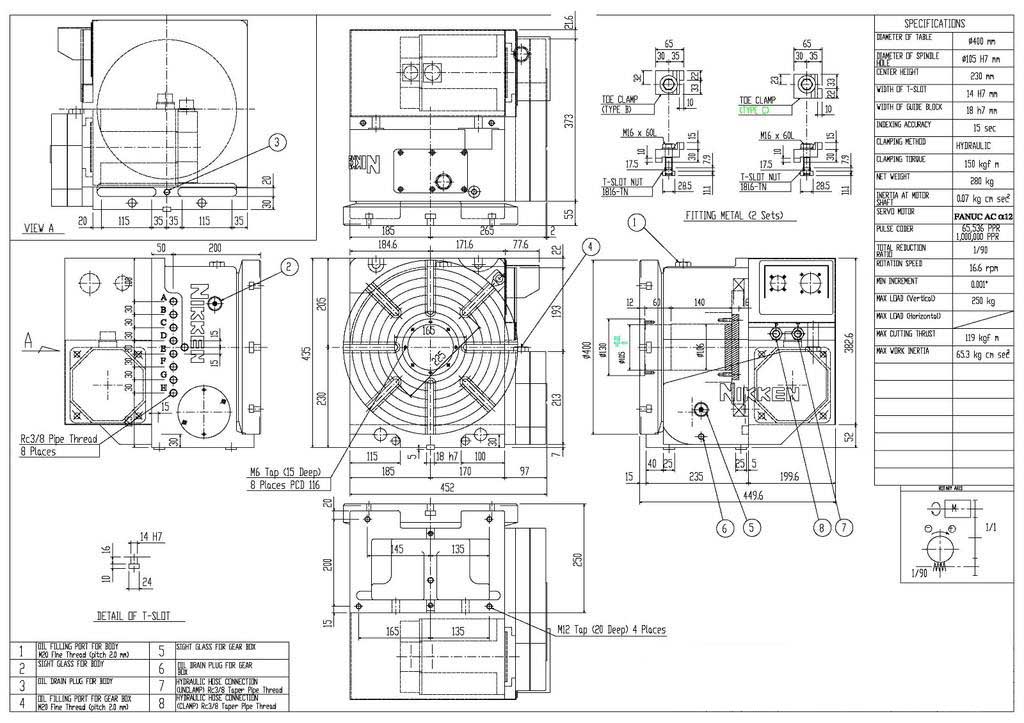

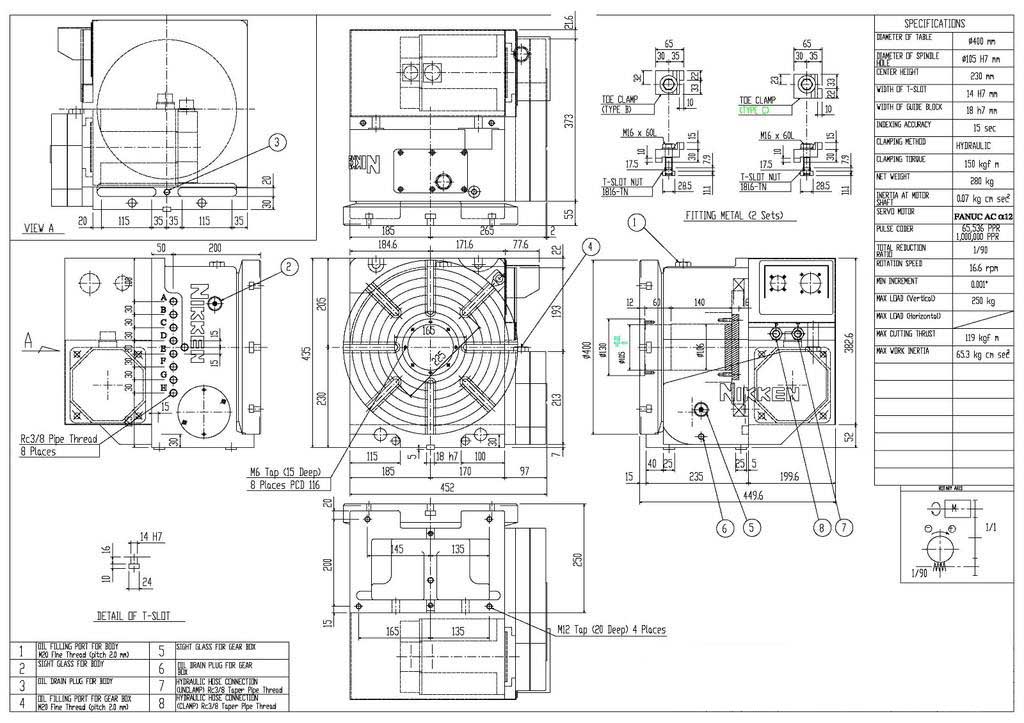

CNC machine tool composition diagram

1, Control Medium

The control medium is a medium for storing all the action tools required for numerical control machining with respect to the workpiece position information, and it records the machining program of the parts. Therefore, the control medium refers to the information carrier that transmits the part processing information to the numerical control device. There are many forms of control media, which vary with the type of numerical control device. Commonly used are perforated tapes, punched cards, magnetic tapes, magnetic disks, and the like. With the development of numerical control technology, punched tape, punch cards become obsolete. The method of using CAD/CAM software in computer programming, and then communicating with the numerical control system through the computer, and transmitting the program and data directly to the numerical control device is more and more widely used.

2, Numerical Control Device

The numerical control device is the core of the numerical control machine tool, and people call it the “central system”. Modern CNC machine tools are used computer numerical control device CNC. The numerical control device includes an input device, a central processing unit (CPU), and an output device, and the like, and the numerical control device can complete information input, storage, conversion, interpolation operation, and realize various control functions.

3, Servo System

The servo system is a drive unit that receives commands from the numerical control device and drives the movement of the machine tool actuator. Including spindle drive unit, feed drive unit, spindle motor and feed motor. When working, the servo system accepts the command information of the CNC system. And according to the requirements of the command information and the position and speed feedback signals, the moving parts of the machine tool or the executing parts are driven. Process parts that meet the requirements of the drawings.

4,Feedback Device

The feedback device consists of a measuring component and a corresponding circuit that detects the velocity and displacement and feeds back the information to form a closed loop control. Some CNC machines with low precision requirements, without feedback devices, are called open loop systems.

5, Machine Body

The machine body is the entity of the CNC machine tool and is the mechanical part that completes the actual cutting process. It includes the bed, the base, the workbench, the saddle, the spindle, and so on.