How to stainless steel milling?

The characteristics of milling stainless steel are:

The adhesion and fusion of stainless steel are strong, and the chips are easy to adhere to the cutter teeth, which deteriorates the cutting conditions; In reverse milling, the cutter teeth slide on the hardened surface first, which increases the tendency of work hardening. When milling, the impact and vibration are large, so that the cutter teeth are easy to collapse and wear. Milling stainless steel end milling cutters and some end mills can be cemented carbide as cutter teeth material. The other kinds of milling cutters are made of high-speed steel, especially tungsten-molybdenum and high vanadium high-speed steel. The tool durability can be increased by 1-2 times than that of W18Cr4V. Carbide grades suitable for making stainless steel milling cutters are YG8, YW2, 813, 798, YS2T, YS30, YS25, and the like.

When milling stainless steel, the cutting edge must be sharp and bear the impact, and the chip pocket should be large. Large helical angle milling cutters (cylindrical milling cutters, end mills) can be used. The screw angle b is increased from 20° to 45° (gn=5°), and the tool durability can be increased by more than 2 times. Because the working front angle g0e of the milling cutter is increased from 11° to over 27° at this time, the milling is light. But the b value should not be larger, especially if the end mill is B or less than 35 degrees, so as not to weaken the cutter teeth.

The stainless steel pipe or thin-walled parts are processed by the wave edge end mill, the cutting is light, the vibration is small, the chips are brittle, and the workpiece is not deformed. High-speed milling with carbide end mills and milling of stainless steel with indexable end mills have achieved good results.

Milling 1Cr18Ni9Ti with silver chip (SWC) end mill. The geometric parameters are gf=5°, gp=15°, af=15°, ap=5°, kr=55°, k′r=35°, g01=-30°, bg=0.4 mm, re=6 mm. When Vc=50-90 m/min, Vf=630-750 mm/min, a'p=2-6 mm, and the feed amount per tooth reaches 0.4-0.8 mm. The milling force is reduced by 10% to 15%, the milling power is reduced by 44%, and the efficiency is greatly improved. The principle is to grind a negative chamfer on the main cutting edge and create a built-up edge when milling. It replaces the cutting edge for cutting, and the front angle gb of the built-up edge can reach 20~~302. Due to the effect of the main yaw angle, the built-up edge is caused by the thrust generated on the rake face parallel to the cutting edge to become the auxiliary swarf, thereby taking away the cutting heat and lowering the cutting temperature.

When milling stainless steel, it should be processed by the down-cut milling method as much as possible. The asymmetric smooth milling method can ensure that the cutting edge is smoothly separated from the metal. The chip bonding contact area is small, and it is easy to be thrown away under the action of high speed centrifugal force. In order to avoid the phenomenon of peeling and flaking when the cutter teeth re-cut into the workpiece, chips impact the rake face, and improve the durability of the cutter.

The spray cooling method is the most effective, which can improve the durability of the milling cutter by more than one time; If the general 10% emulsion is cooled, the flow of cutting fluid should be ensured to achieve full cooling. When milling carbide with carbide milling cutter, take Vc=70~150 m/min, Vf=37.5~150 mm/min, and adjust it according to the alloy grade and workpiece material.

The cutting amount of high speed steel milling cutter is shown in Table 6.

| Table 6. Milling amount when machining stainless steel with high speed steel milling cutter | ||||

| Type of milling cutter |

Milling cutter diameter d0 (mm) |

Spindle speed n (r/min) |

Feed rate f (mm/min) |

Remarks |

| End mill | 3~4 | 1180~750 | Manual |

1. When the milling width and milling depth are small, the feed amount f takes a large value; otherwise, it takes a small value. 2. When milling martensitic stainless steel such as 2Cr13, the milling amount should be adjusted according to the actual hardness of the workpiece material. 3. When milling concentrated nitric acid resistant stainless steel, the milling speed and feed rate should be appropriately reduced. |

| 5~6 | 750~475 | |||

| 8~10 | 600~375 | |||

| 12~14 | 375~235 | 30~37.5 | ||

| 16~18 | 300~235 | 37.5~47.5 | ||

| 20~25 | 235~190 | 47.5~60 | ||

| 32~36 | 190~150 | 47.5~60 | ||

| 40~50 | 150~118 | 47.5~75 | ||

| Waved edge end mill | 36 | 190~150 | 47.5~60 | |

| 40 | 150~118 | |||

| 50 | 118~95 | |||

| 60 | 95~75 | 60~75 | ||

|

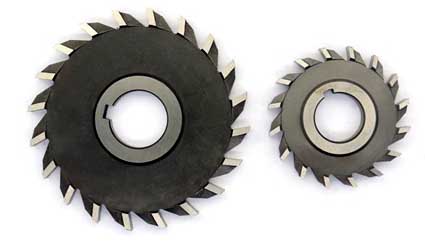

Saw blade milling cutter with Three-sided milling cutter |

75 | 235~150 | 23.5 Or manual | |

| 110 | 150~75 | |||

| 150 | 95~60 | |||

| 200 | 75~37.5 | |||