My company produces a variety of sizes SUS303,304,316F stainless steel precision turned parts, lathe pieces.

The product on the left is a typical stainless steel turned part produced by our company. It is made of stainless steel with threaded, stepped and hexagonal edges. It is made of SUS303 stainless steel. The thread size is M4. The maximum outer diameter (ie its head diameter) : 10mm, total length 38mm The product on the left is a typical stainless steel turned part produced by our company. It is made of stainless steel with threaded, stepped and hexagonal edges. It is made of SUS303 stainless steel. The thread size is M4. The maximum outer diameter (ie its head diameter) : 10mm, total length 38mmFeatures: Axial face milling hex, large turning, high precision, semi-finished products using automatic lathe + Hydraulic milling machine milling hexagon + Rolling machine rolling teeth, this turning part is applied to a well-known electrical appliance. Since the fastening and regulation. Our stainless steel materials include: SUS303 stainless steel, SUS400 stainless steel, SUS316F, and customer specified materials. Our company's turned parts are widely used in all walks of life. In the following part of this page, we will show several representative examples of products that we often process. |

Two stainless steel precision turning parts with internal thread, using various automatic lathe machining parts made of SUS303 Two stainless steel precision turning parts with internal thread, using various automatic lathe machining parts made of SUS303The main process: turning, embossing, milling, rolling (or teeth), drilling, tapping, etc. The small product specification on the left is M4*5*16 (thread * maximum outside diameter * total length, unit: MM, the same below), and is a straight-lined internal thread product. The large product specification is M5*12*16, with one end milling on both sides |

Stainless steel precision turning parts with pressure teeth Stainless steel precision turning parts with pressure teethThis is a stainless steel pin developed and produced for a well-known international communication company. The step has a large amount of disposable cutting. Tooth pitch 0.8MM, can be firmly inserted into the hole and prevent loosening/rotation. Features: Disposable cutting large stepped sweep, The straight grain embossing is symmetrical with the tooth thread. Technology and equipment is the greater test |

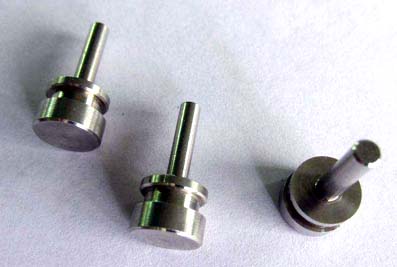

This is a special screw (in foreign countries is also a standard): This is a special screw (in foreign countries is also a standard):SHOULDER SCREW, Cypriot screws,Contour screws, The axial surface precision requirements are often relatively high, the axial surface diameter tolerance is generally 0.01MM, the surface roughness is 0.8üm. Material: SUS303 Process: Automatic Turning Forming - Punching Hex Holes - Rolling. Features: High surface accuracy / fills the gap of domestic stainless steel contour screws. |

Compare the size of stainless steel turned parts, click on the left to see a comparison of the two turning parts Compare the size of stainless steel turned parts, click on the left to see a comparison of the two turning partsThe size of the two threaded turning parts is in sharp contrast to show the range of stainless steel parts that our company can produce and process. The threads are from M1.6 to M16, and the smallest large circle size can be processed from φ2.0 to φ32. The specifications of the small size stainless steel turning parts in the left picture are M2*5 (head diameter)*20 (total length) The specifications of the large-sized stainless steel turning parts on the left are M12*18*78, It is the thread Lathes pick teeth, rather than simply hobbing teeth, The upper part is knurled and milled bilaterally. The outer diameter of knurling is 12MM and the length is 28MM. If there is a large area of stainless steel knurled, We used a custom knurling wheel to press out the pattern on a Hobbing machine. The principle is similar to hobbing teeth. The large size stainless steel turning parts, As exquisite as crafts, If your monitor has a resolution greater than 1024*768, you can't appreciate its full-size picture. |

Stainless Steel Turned Parts with Milling and Internal Threads Stainless Steel Turned Parts with Milling and Internal ThreadsOn the left is a multi-stepped shaft with a turned part with double-sided milling at one end. One end is M4 male thread and the other end is M4 female thread |

Knurled stainless steel nuts, automatic lathe turning a one-time completion. This is a common part of the plastics industry. By heating the nut, It can be pressed into the prefabricated hole of the plastic part and cooled to form a stainless steel internal thread. Knurled stainless steel nuts, automatic lathe turning a one-time completion. This is a common part of the plastics industry. By heating the nut, It can be pressed into the prefabricated hole of the plastic part and cooled to form a stainless steel internal thread.Our company also produces other kinds of similar embedded stainless steel embedded mother, see stainless steel embedded nuts |

Special screws with hexagonal bar turning Special screws with hexagonal bar turningMaterial: SUS303 imported stainless material, At the same time, it can also produce SUS410/416/420 (highest hardness of heat treatment up to HRC50) and SUS316F (higher rust resistance), High precision, exquisite appearance. Especially good at shafts, steps, milling, threaded parts. Can be produced according to customer drawings. Maximum processing outside diameter 32mm, the longest processing length 80mm or longer A stainless steel turned part with internal hole blind hole With recessed and protruding sealing steps on the head, it is turned into a basin containing rubber seals. After installation on the workpiece, it can be used as a waterproof and oil-proof seal. Stainless steel hexagonal support column Made of stainless steel hexagonal rods, it is widely used in a variety of circuit boards, cabinets, electrical and other products, its role is to connect the two parts together and play a supporting role. |

Inside and outside threaded stainless steel turning parts, Inside and outside threaded stainless steel turning parts,In the drawing, the left product has the thread in the form of internal and external teeth, external thread M5, internal thread M3 Right in the picture, stainless steel screws, surface roughness up to 0.8um, the largest processing diameter of 20MM below the product can be automatically processed by our company at one time, more than 20mm diameter also processed through multiple processes High precision, fast efficiency. Widely used in all kinds of beautiful rust-proof use of places. Axial surface one-time scanning section of 10mm, dimensional stability, degree of smoothness. At the same time, for the larger deformation of the screw, non-standard parts also have advantages. |