Choosing the Right Tool for CNC Machining

It is important to choose the correct CNC tool when programming. The general requirements for CNC tools are easy installation and adjustment, good rigidity, high precision and good durability. On this basis, comprehensive consideration of the cutting performance of the workpiece material, the processing capacity of the machine tool, the type of CNC machining process. The amount of cutting and many factors related to the working range of the machine tool and numerical control device.

1. Factors affecting the selection of CNC tools

When choosing the type and specification of the tool, the main factors are considered:

(1) Nature of production

The production property here refers to the batch size of the parts, mainly considering the influence on the tool selection from the processing cost. For example, the use of special tools in mass production may be cost-effective. In small batch production, the choice of standard tools is more suitable.

(2) Machine type

Complete CNC machine tools used in this step, selection of the type of the tool (drill, turning tool or a milling-tool) effects. High productivity tools such as high speed cutting tools and large feed turning tools are allowed under the condition that the workpiece system and the tool system are rigid.

(3) CNC machining plan

Different types of tools can be used for different CNC machining solutions. For example, the machining of holes can be done with drills and reamers, or with drills and boring tools.

(4) Size and shape of the workpiece

The size and shape of the workpiece also influences the choice of tool type and specification. For example, special surfaces are machined with special tools.

(5) Machining surface roughness

The surface roughness of the machined surface affects the structural shape and cutting amount of the tool. For example, when rough roughing, rough tooth milling cutters can be used, and fine milling cutters are best used for finishing milling.

(6) Machining accuracy

Machining accuracy affects the type and shape of the finishing tool. For example, the final machining of the hole can be processed by drilling, reaming or boring according to the accuracy of the hole.

(7) Workpiece material

The workpiece material will determine the choice of the tool material and the geometry of the cutting part. The tool material is related to the machining accuracy of the workpiece and the material hardness.

2. Performance requirements of CNC tools

Because CNC machine tools have the characteristics of high machining precision, high machining efficiency, concentrated machining process and few parts clamping times, higher requirements are imposed on the CNC tools used.

In terms of tool performance, CNC tools should be higher than those used in ordinary machine tools.

When selecting a CNC tool, the first choice is to use the standard tool first. If necessary, you can use a variety of high-efficiency compound tools and special special tools. When selecting a standard CNC tool, it should be combined with the actual situation, as far as possible to choose a variety of advanced tools, such as indexable tools, solid carbide tools, ceramic tools.

When choosing a CNC machine tool, you should also consider the following aspects:

(1) The type, specification and accuracy level of the CNC tool should be able to meet the machining requirements, and the tool material should be compatible with the workpiece material.

(2) Good cutting performance.

In order to adapt to the tool's large backing and high feed rate during roughing or machining of difficult-to-machine materials, the tool should be able to withstand high-speed cutting and powerful cutting. At the same time, the same batch of tools must be stable in terms of cutting performance and tool life in order to achieve tool change according to tool life or to manage tool life by CNC system.

(3) High precision.

In order to meet the requirements of high precision and automatic tool change of CNC machining, the tool must have high precision. For example, the integral end mill has a radial dimensional accuracy of up to 0.005 mm.

(4) High reliability.

It is necessary to ensure that the tool will not be accidentally damaged and potential defects in the CNC machining, which will affect the smooth progress of the machining. It is required that the tool and the accessories combined with it must have good reliability and strong adaptability.

(5) High durability.

CNC machining tools, whether in roughing or finishing, should have higher durability than those used in conventional machine tools. In order to minimize the number of replacement or grinding tools and tool setting, thereby improving the processing efficiency of CNC machine tools and quality assurance process.

(6) Good chip breaking and chip removal performance.

In CNC machining, chip breaking and chip removal are not handled manually by hand, as in ordinary machine tools. Chips tend to wrap around the tool and the workpiece, damaging the tool and scratching the machined surface, and can even cause injury and equipment accidents. Affects the quality of the machine and the safe operation of the machine tool, so the tool is required to have better chip breaking and chip removal performance.

3. Tool selection method

The choice of tool is one of the important contents in the CNC machining process, which not only affects the machining efficiency of the machine tool, but also directly affects the machining quality of the part. Because the spindle speed and range of CNC machine tools are much higher than ordinary machine tools, and the spindle output power is large. Therefore, compared with the traditional processing method, higher requirements are imposed on the CNC machining tool, including high precision, high strength, good rigidity, high durability, stable size, and convenient installation and adjustment. This requires reasonable structure of the tool, standardization of geometric parameters, and serialization. CNC tools are one of the prerequisites for improving machining efficiency. Its choice depends on the geometry of the part being machined, the state of the material, the rigidity of the fixture and the tool selected for the machine.

The following aspects should be considered:

(1) Select the tool according to the cutting performance of the part material. For turning or milling high-strength steel, titanium alloy, and stainless steel parts, it is recommended to select an indexable carbide tool with good wear resistance.

(2) Select the tool according to the machining stage of the part.

That is, the roughing stage is mainly to remove the margin, and the tool with better rigidity and lower precision should be selected. In the semi-finishing and finishing stages, in order to ensure the machining accuracy and product quality of the parts, tools with high durability and high precision should be selected. The tool used in the roughing stage has the lowest precision and the tool used in the finishing stage has the highest precision. If the same tool is selected for rough and finish machining, it is suggested that the tool eliminated from finish machining should be selected for rough machining. Because the tool wear condition of finishing finishing is mostly the slight wear of the blade, the coating wears and repairs the light, and the continuous use will affect the processing quality of the finishing, but the impact on the roughing is small.

(3) The tool and geometry parameters are selected according to the characteristics of the machining area. A tool with a large diameter and a small aspect ratio should be used if the part structure permits; The center-cutting edge of a thin-walled, ultra-thin wall part should have sufficient centripetal angle to reduce the cutting force of the tool and the cutting part. When processing parts such as aluminum and copper, you should select an end mill with a slightly larger front corner and the number of teeth should not exceed 4 teeth.

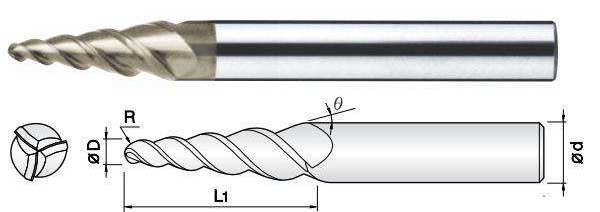

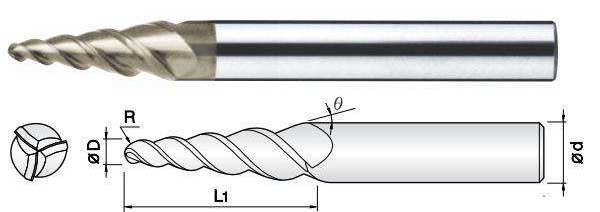

When selecting a tool, the size of the tool should be adapted to the surface size of the workpiece being machined. In the production, the peripheral contour of the plane parts is often processed by an end mill; When milling the plane, the cemented carbide insert milling cutter should be selected; When machining bosses and grooves, select high speed steel end mills; When processing the surface of the blank or roughing the hole, a corn milling cutter with a carbide insert can be selected; For the machining of some three-dimensional and variable-angle contours, ball-end milling cutters, ring milling cutters, conical milling cutters and disc milling cutters are often used.

In the free-form surface machining, since the cutting speed of the end of the ball-end tool is zero, in order to ensure the machining accuracy, the cutting pitch is generally small, so the ball-end milling cutter is suitable for the finishing of the curved surface.

The end mill is far superior to the ball end mill in both surface quality and machining efficiency. Therefore, when it is necessary to ensure that the parts are not cut, when roughing and semi-finishing the surface, try to select the end mill. In addition, the durability and accuracy of the tool are highly dependent on the tool price and must be noted.

In most cases, the choice of a good tool increases the cost of the tool, but the resulting increase in processing quality and processing efficiency can greatly reduce the overall processing cost.

In the machining center, all the tools are pre-installed in the tool magazine, and the corresponding tool change is performed by the tool selection and tool change commands of the NC program. The corresponding standard shank for the machine tool system specification must be selected so that the CNC machining tool can be quickly and accurately mounted to the machine spindle or returned to the tool magazine. The programmer should be able to understand the structure size, adjustment method and adjustment range of the tool holder used in the machine tool to ensure that the radial and axial dimensions of the tool are determined during programming, and the order of the tools is arranged reasonably.

1. Factors affecting the selection of CNC tools

When choosing the type and specification of the tool, the main factors are considered:

(1) Nature of production

The production property here refers to the batch size of the parts, mainly considering the influence on the tool selection from the processing cost. For example, the use of special tools in mass production may be cost-effective. In small batch production, the choice of standard tools is more suitable.

(2) Machine type

Complete CNC machine tools used in this step, selection of the type of the tool (drill, turning tool or a milling-tool) effects. High productivity tools such as high speed cutting tools and large feed turning tools are allowed under the condition that the workpiece system and the tool system are rigid.

(3) CNC machining plan

Different types of tools can be used for different CNC machining solutions. For example, the machining of holes can be done with drills and reamers, or with drills and boring tools.

(4) Size and shape of the workpiece

The size and shape of the workpiece also influences the choice of tool type and specification. For example, special surfaces are machined with special tools.

(5) Machining surface roughness

The surface roughness of the machined surface affects the structural shape and cutting amount of the tool. For example, when rough roughing, rough tooth milling cutters can be used, and fine milling cutters are best used for finishing milling.

(6) Machining accuracy

Machining accuracy affects the type and shape of the finishing tool. For example, the final machining of the hole can be processed by drilling, reaming or boring according to the accuracy of the hole.

(7) Workpiece material

The workpiece material will determine the choice of the tool material and the geometry of the cutting part. The tool material is related to the machining accuracy of the workpiece and the material hardness.

2. Performance requirements of CNC tools

Because CNC machine tools have the characteristics of high machining precision, high machining efficiency, concentrated machining process and few parts clamping times, higher requirements are imposed on the CNC tools used.

In terms of tool performance, CNC tools should be higher than those used in ordinary machine tools.

When selecting a CNC tool, the first choice is to use the standard tool first. If necessary, you can use a variety of high-efficiency compound tools and special special tools. When selecting a standard CNC tool, it should be combined with the actual situation, as far as possible to choose a variety of advanced tools, such as indexable tools, solid carbide tools, ceramic tools.

When choosing a CNC machine tool, you should also consider the following aspects:

(1) The type, specification and accuracy level of the CNC tool should be able to meet the machining requirements, and the tool material should be compatible with the workpiece material.

(2) Good cutting performance.

In order to adapt to the tool's large backing and high feed rate during roughing or machining of difficult-to-machine materials, the tool should be able to withstand high-speed cutting and powerful cutting. At the same time, the same batch of tools must be stable in terms of cutting performance and tool life in order to achieve tool change according to tool life or to manage tool life by CNC system.

(3) High precision.

In order to meet the requirements of high precision and automatic tool change of CNC machining, the tool must have high precision. For example, the integral end mill has a radial dimensional accuracy of up to 0.005 mm.

(4) High reliability.

It is necessary to ensure that the tool will not be accidentally damaged and potential defects in the CNC machining, which will affect the smooth progress of the machining. It is required that the tool and the accessories combined with it must have good reliability and strong adaptability.

(5) High durability.

CNC machining tools, whether in roughing or finishing, should have higher durability than those used in conventional machine tools. In order to minimize the number of replacement or grinding tools and tool setting, thereby improving the processing efficiency of CNC machine tools and quality assurance process.

(6) Good chip breaking and chip removal performance.

In CNC machining, chip breaking and chip removal are not handled manually by hand, as in ordinary machine tools. Chips tend to wrap around the tool and the workpiece, damaging the tool and scratching the machined surface, and can even cause injury and equipment accidents. Affects the quality of the machine and the safe operation of the machine tool, so the tool is required to have better chip breaking and chip removal performance.

3. Tool selection method

The choice of tool is one of the important contents in the CNC machining process, which not only affects the machining efficiency of the machine tool, but also directly affects the machining quality of the part. Because the spindle speed and range of CNC machine tools are much higher than ordinary machine tools, and the spindle output power is large. Therefore, compared with the traditional processing method, higher requirements are imposed on the CNC machining tool, including high precision, high strength, good rigidity, high durability, stable size, and convenient installation and adjustment. This requires reasonable structure of the tool, standardization of geometric parameters, and serialization. CNC tools are one of the prerequisites for improving machining efficiency. Its choice depends on the geometry of the part being machined, the state of the material, the rigidity of the fixture and the tool selected for the machine.

The following aspects should be considered:

(1) Select the tool according to the cutting performance of the part material. For turning or milling high-strength steel, titanium alloy, and stainless steel parts, it is recommended to select an indexable carbide tool with good wear resistance.

(2) Select the tool according to the machining stage of the part.

That is, the roughing stage is mainly to remove the margin, and the tool with better rigidity and lower precision should be selected. In the semi-finishing and finishing stages, in order to ensure the machining accuracy and product quality of the parts, tools with high durability and high precision should be selected. The tool used in the roughing stage has the lowest precision and the tool used in the finishing stage has the highest precision. If the same tool is selected for rough and finish machining, it is suggested that the tool eliminated from finish machining should be selected for rough machining. Because the tool wear condition of finishing finishing is mostly the slight wear of the blade, the coating wears and repairs the light, and the continuous use will affect the processing quality of the finishing, but the impact on the roughing is small.

(3) The tool and geometry parameters are selected according to the characteristics of the machining area. A tool with a large diameter and a small aspect ratio should be used if the part structure permits; The center-cutting edge of a thin-walled, ultra-thin wall part should have sufficient centripetal angle to reduce the cutting force of the tool and the cutting part. When processing parts such as aluminum and copper, you should select an end mill with a slightly larger front corner and the number of teeth should not exceed 4 teeth.

When selecting a tool, the size of the tool should be adapted to the surface size of the workpiece being machined. In the production, the peripheral contour of the plane parts is often processed by an end mill; When milling the plane, the cemented carbide insert milling cutter should be selected; When machining bosses and grooves, select high speed steel end mills; When processing the surface of the blank or roughing the hole, a corn milling cutter with a carbide insert can be selected; For the machining of some three-dimensional and variable-angle contours, ball-end milling cutters, ring milling cutters, conical milling cutters and disc milling cutters are often used.

In the free-form surface machining, since the cutting speed of the end of the ball-end tool is zero, in order to ensure the machining accuracy, the cutting pitch is generally small, so the ball-end milling cutter is suitable for the finishing of the curved surface.

The end mill is far superior to the ball end mill in both surface quality and machining efficiency. Therefore, when it is necessary to ensure that the parts are not cut, when roughing and semi-finishing the surface, try to select the end mill. In addition, the durability and accuracy of the tool are highly dependent on the tool price and must be noted.

In most cases, the choice of a good tool increases the cost of the tool, but the resulting increase in processing quality and processing efficiency can greatly reduce the overall processing cost.

In the machining center, all the tools are pre-installed in the tool magazine, and the corresponding tool change is performed by the tool selection and tool change commands of the NC program. The corresponding standard shank for the machine tool system specification must be selected so that the CNC machining tool can be quickly and accurately mounted to the machine spindle or returned to the tool magazine. The programmer should be able to understand the structure size, adjustment method and adjustment range of the tool holder used in the machine tool to ensure that the radial and axial dimensions of the tool are determined during programming, and the order of the tools is arranged reasonably.