Characteristics and Application of Straight Groove Drill Bit

The traditional notion that "spiral groove drills are irreplaceable" is now being overturned by the processing performance of straight groove drills. In some machining applications, straight groove drilling is becoming a better tool choice than twist drills.

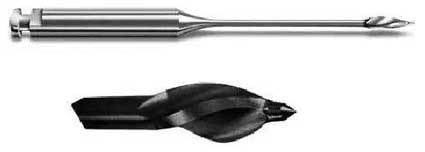

The "pioneer" of modern straight groove drills is die drills. This drill has a short size, good rigidity and a strong drill tip. It is suitable for drilling hard steel materials with low spindle speed and low feed rate. Its high strength and high rigidity make it possible to machine holes with good straightness and roundness. The reason why the die bit can achieve good machining results is because the material to be processed when designing the drill bit is usually a metal that produces short chips. Chip control remains a key issue in the processing of straight groove drill bits. Straight groove drilling is best achieved only when processing materials that do not produce long tendril-like chips. These materials include cast iron, powdered alloy (P/M), medium-high silicon content (6% or higher) silicon aluminum alloy, and the like.

However, with advances in machine tool technology, coolant delivery technology, and tool geometry design, the range of machining applications for straight groove drilling is expanding. The traditional way of thinking is that the spiral groove of the drill bit is indispensable for chip removal. The straight groove drill can only be used to drill shallow holes with a hole depth of 2D ~ 3D (D is the hole diameter) on aluminum and cast iron. However, the high-pressure cooling system developed today and the higher spindle speed of the machine tool have greatly improved the chip breaking and chip removal performance of the internally-cooled straight groove drill.

Straight groove drills can provide far better processing performance than spiral groove drills in suitable conditions. Straight groove drills have the advantage of being able to machine holes with higher roundness and straightness, and they cut faster than standard cobalt or high speed steel drills. For example, when a 0.39" (φ10 mm) Guhring RT150GG straight groove drill is used instead of a twist drill to process an aluminum part, the cutting speed of the twist drill is 50 sfm (15 m/min), and the feed rate is 0.005 ipr (0.127 mm/r); The cutting speed of the straight groove drill can reach 800sfm (245m/min), and the feed rate is 0.007ipr (0.178mm/r). The cutting time for straight groove drilling is only 1/10 of the twist drill.

Part of the reason for straight groove drilling to significantly increase machining efficiency is based on the basic design of the drill bit – the straight groove provides a direct path for the chip discharge orifice. However, since the cutting edge of the straight groove drill bit lacks a positive rake angle, its chip and chip breaking ability is poor, especially when processing a ductile material.

Cutting speed (especially a sufficiently high cutting speed) is another factor in the successful application of straight groove drilling. The faster the cutting speed, the smaller the chips formed. Straight groove drilling achieves high productivity through faster spindle speeds rather than higher feed rates.

Many high-performance, high-drilling twist drills have considerable chamfering on the cutting edge. This requires that the feed of the drill bit into operation should exceed the chamfer size of the cutting edge so that the cutting edge can cut the workpiece material rather than just pushing it. For some machining applications and materials to be processed, the cutting edge of the twist drill works well. These twist drills are usually drilled at a higher feed rate than the straight groove, but at a lower cutting speed than the straight groove drill.

By using a reasonable combination of coolant pressure and cutting speed, straight grooved drills can also efficiently process workpiece materials that do not necessarily produce short chips. For example, the effect of machining 1144 stress-resistant steel with straight groove drilling is very good, the chip breaking is smooth and the chips are small, and no built-up edge is formed. The drill bit used for processing is H.A.M., Precision's 294-0500, non coated internal cooling straight drill bit: (diameter φ5mm), drilling depth is 48mm, cutting speed is 185sfm (63m/min), feed rate is 0.003ipr (0.076mm/r), and coolant pressure is 1500psi. The content of manganese sulfide in the 1144 alloy is high, which is conducive to chip breaking. However, to successfully process this material, a high coolant pressure is required (experience has shown that the coolant pressure should be above 600 psi, preferably at 1000 psi, 1200 psi or higher).

For straight groove drilling, in addition to chip control, built-up edge may also be a problem. This is because the material of the removed workpiece passes through the cutting edge as it exits the straight slot drill center and is pushed toward the drill bit of the drill bit. One way to avoid the formation of built-up edge is to use a drill with a smooth surface and a high finish; The use of coated drill bits also helps prevent the formation of built-up edges. Molybdenum disulfide (MoS2) coatings, which are widely used in aluminum processing, have similar properties to Teflon and are not easily bonded to other materials. The use of such coated drill bits is excellent in applications where it is necessary to prevent the formation of built-up edges.

The straight-drilled drill tip structure allows two edges to be sharpened at the outer edge of each straight groove. Since the drill bit has four contact points with the workpiece, the drill bit is more stable during processing, which improves machining accuracy.

The large apex angle of the straight groove drill bit also helps to improve its processability. For example, H.A.M. Precision's standard straight-groove bit uses a 140 degree vertex, similar to a separate top drill, which can be drilled with very small thrust. In addition, the large apex angle ensures that the entire diameter of the drill bit is quickly engaged with the workpiece material, minimizing the possibility of the drill bit "running off".

In many machining situations, it is best to first machine a starting hole (pre-hole) with a pilot bit (center drill) whose apex angle is greater than the apex angle of the carbide straight groove drill bit. In this way, the center of the drill point (horizontal edge) of the straight groove drill can be guaranteed to enter the pre-hole first in order to avoid the edge breakage caused by the first contact of the brittle carbide cutting edge with the workpiece. Another strategy for using straight groove drilling is to simply determine the hole position before starting the drilling, because even the surface of the workpiece that has been machined may have defects, and the operator only needs to touch the hole with the drill bit to determine its position. As long as the horizontal edge of the bit contacts the workpiece first, the bit will not "deviate" and the positioning hole can play a similar role as a drill sleeve.

The straightness of the hole measured when machining φ10 mm holes on cast iron material with three different drill bits indicates: The high-speed steel spiral groove drill has a cutting speed of 98sfm (30m/min) and a feed rate of 7.66ipm (195mm/min). The external cooling method is adopted, and the processing quality of the hole reaches IT12; The solid carbide spiral groove drill has a cutting speed of 295sfm (90m/min). The feed rate is 34.5ipm (876mm/min), and the internal cooling method is 440psi/2.4-gpm with the coolant pressure. The processing quality of the hole reaches IT9; The straight groove drill has a cutting speed of 425sfm (130m/min), a feed rate of 33.3ipm (845mm/min), and an internal cooling method with a coolant pressure of 735psi/3.2-gpm. The processing quality of the hole reaches IT8.

Many people refer to all straight-groove drills as “G-drills,” but this is not true. In fact, “G-drills” are just the trade names for a class of straight-groove drills produced by Accuromm USA Int. The outer edge of the tail of such a drill bit can squash the wall of the hole.

Compare the hole wall finish that can be achieved with various hole machining tools. In general, high-speed steel drill bits are about 125-rms, cemented carbide spiral groove high-efficiency drills are about 63-rms, and three-slot reamer is about 32-rms. The G-drill can reach 16-rms or less and has reached the finish level of finishing.

In order to process holes of different quality levels, Accuromm has designed different drill bits. The company's G-drills generally meet the hole machining requirements of the H9 tolerance standard, while the company's G-7 drills combine drilling and reaming to meet H7 tolerance requirements. For example, Accuromm cited an example of a machining method in which a straight groove G-drill replaces a twist drill on an aluminum material. The diameter of the G drill is 0.394" (φ 10 mm), the cutting speed is 330 ft. / min (100 m / min), and the feed amount is 0.008 ipr (0.20 mm / r). The results show that the hole machining accuracy is significantly improved, and the aperture error is reduced from the original ±0.0032" (0.08mm) to ±0.0012" (0.03mm). Under the same cutting parameters, such as with a G-7 drill, the aperture error can be reduced to ±0.0008" (0.02 mm). Because the drilling quality of straight groove drill is high, it is also helpful for other hole processing. Accuromm points out that its excellent dimensional accuracy can increase tap life by about 50% if tapping holes processed by straight-grooved bits is required.

The improvement in the performance of cutting tools almost always requires a narrower range of objects to be machined. Although straight groove drilling is far from being a general-purpose tool, its scope of use is expanding. The popularization of straight groove drilling can achieve significant benefits in terms of improving machining efficiency and improving workpiece quality.

H.A.M. Precision's "Muilt-Drill" integral carbide straight-groove stepped drill uses TiAlN coating and internal cooling channel design, which is suitable for drilling, stepped hole and chamfering on short chip aluminum alloy materials.

The "Insatiable G-Spot" special compound tool from Competitive Carbide Int. combines the company's G-Spot straight groove drill with the internal cavity cutter. A variety of machining of the workpiece geometry can be done with a single tool. The tool can perform a total of nine machining operations, including drilling, outer diameter (OD) chamfering and boring, inner diameter (ID) chamfering and boring, and OD turning (pre-machining of threaded workpieces). Since the contact area between the tool and the workpiece is large, and the outer diameter of the drill bit is in contact with the workpiece at 4 points, the two-piece tool helps to maintain the position of the workpiece and provide additional clamping action to the workpiece. Since the straight groove drill has 2 belts, the tool can not only drill holes, but also squeezing the holes. This means that the finished hole has a higher finish and better straightness, and can better meet the specific size requirements of the hole compared to a conventional drill having only one cutting edge. The Insatiable G-Spot composite tool can replace at least 3 to 4 tools, that is, if the original tool is used, it takes 3 times to change the tool and complete 4 machining operations. Therefore, the use of such a multifunctional composite tool is beneficial for improving processing efficiency and shortening processing time.