Case Study on Gear Parts Processing of 40Cr Straight Tooth Cylindrical Steam Turbine

Keywords: gear parts, gear parts processing, gear processing cases, 40Cr gears, turbine gears, gear grinding, gear processing technology, tooth end processing, tooth end inverted circle, gear quenching

The gear is a standard spur gear with a modulus m=3.5 mm, a number of teeth z=63, and a tooth shape angle a = 20 & ordm. Because it is the gear in the aircraft steam turbine, its processing accuracy is required to be high.

Because the gears in steam turbine require hard tooth surface and tough tooth center, the forged blank is selected; 40Cr is used.

(1) Main technical requirements

1) The accuracy level is set to the first tolerance group with 6 levels of accuracy, and the detected item pitch cumulative error ΔFp; The second tolerance group is level 5 accuracy, and the detection item tooth profile error Δff and the base section deviation Δfpb; The third tolerance group is level 5 accuracy, and the detected item tooth direction error ΔFβ; Measuring the tooth thickness deviation Wk by measuring the length of the normal line; Deviation code M on tooth thickness, deviation code P under tooth thickness; (In the accuracy level indication, the tooth thickness limit deviation is used to control the backlash, which is denoted by the code MP).

2) The reference depth of the reference surface of the blank is the accuracy of the IT6; There are requirements for the circular runout of the end face with the axis of the inner hole at both ends.

3) Surface roughness Ra The reference hole was 0.8 μm, the both end faces were 1.6 μm, the tooth surface was 0.8 μm, and the tooth top cylindrical surface was 3.2 μm.

(2) Forging blank is chosen to improve the mechanical properties of the material. Free forging is used in small batch production, and die forging is used in mass production.

(3) The selection of the main surface processing methods for the gear has a higher precision level. The main surface finishing methods are as follows.

Reference hole: grinding

End face: grinding

Tooth surface: hobbing - surface quenching - grinding

The general process of machining aircraft turbine spur gears:

Document Number of Parts and Components of Process Card Product Type

Product Name Gear Parts Name Total Page

No. Process Content Equipment Quantity Measuring Time Quota Remarks

1, cutting sawing machine 1

2, rough car end face, inner hole and chamfering vertical car

3, blank inspection nondestructive flaw detector

4, rough car mouth, external chamfer and face lathe

5, heat treatment (tempering) box furnace

6, fine car inner hole and end face lathe

7. Drilling: Vertical Drilling

8. Grinding large end face: surface grinder

9, reaming: drilling machine

10, pull key: slot broaching machine

11. Intermediate inspection: calipers and angle rulers

12. Make factory standard: bench bench

13, Rough Hobbing: Hobbing Machine

14. Fine Hobbing: Hobbing Machine

15. Tooth End Processing: Milling Machine

16. Cleaning: Cleaning Machine

17. Intermediate test

18, Heat Treatment (Surface Hardening): Box Furnace

19. Fine grinding inner hole: inner grinder

20, Cleaning: Cleaning Machine

21. Intermediate test

22, Matching: Inspection Machine

23, Grinding: Grinding Machine

24, Cleaning: Cleaning Machine

25, Matching: Inspection Machine

26. Write the pairing number

27, Cleaning: Cleaning Machine

28. Final test

Design proofreading approval

The gear processing process generally goes through the following stages: Blank heat treatment, tooth blank machining, tooth profile machining, tooth end machining, tooth surface heat treatment, precision benchmark correction and tooth profile finishing, etc.

The first stage of processing is the initial stage in which the blank is initially machined. Since the gear transmission accuracy is mainly determined by the tooth profile accuracy and the tooth pitch distribution uniformity, this has a direct relationship with the accuracy of the positioning reference (hole and end face) used when cutting the tooth. Therefore, this stage is mainly to prepare the fine reference for the next stage machining tooth shape, so that the accuracy of the inner hole and the end surface of the tooth basically meets the specified technical requirements. In addition to machining the benchmarks at this stage, the processing of minor surfaces other than the tooth profile should be done as late as possible in this phase.

The second stage is the processing of the tooth shape.

For gears that do not require quenching, this stage is generally the final machining stage of the gear. After this stage, gears that fully meet the requirements of the drawings should be machined. For gears that require hardening, the tooth profile accuracy required to meet the final finishing of the tooth profile must be machined at this stage, so machining at this stage is a critical stage in ensuring gear machining accuracy.

Special attention should be paid.

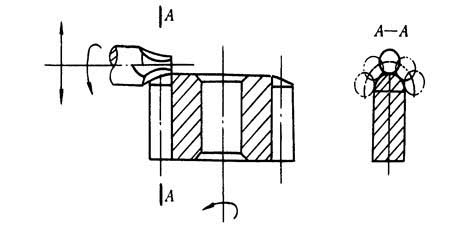

Tooth end processing:

A)Inverted circle

B) inverted tip

C) chamfering

Figure 1 tooth end processing

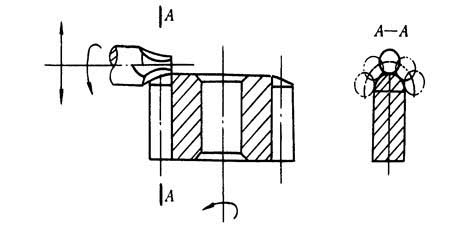

The gear end machining methods of the gear are: There are four ways of inverted circle, inverted point, chamfered edge and deburring. The gear after chamfering, chamfering and chamfering (Fig. 1). It is easy to engage when moving along the axis. Tooth end chamfering is the most widely used. Figure 2 shows the principle of finger milling cutter chamfering. When rounded, the gear rotates slowly, and the finger cutter reciprocates linearly along the gear axis while rotating at high speed. Each time the gear rotates one tooth, the milling cutter reciprocates once, and the two ends complete the tooth end rounding in relative motion. Tooth end processing should be arranged before tooth profile quenching.

The third stage of processing is the heat treatment stage. At this stage, the quenching treatment of the tooth surface is mainly performed to achieve the specified hardness requirement of the tooth surface.

The final stage of machining is the finishing phase of the tooth profile.

The purpose of this stage is to correct the tooth profile deformation caused by the quenching of the gear, further improve the tooth profile accuracy and reduce the surface roughness to achieve the final accuracy requirements. In this stage, the positioning datum (hole and end face) should be trimmed first, and the inner hole and end face of the gear will be deformed after quenching. If the hole-shaped finishing is directly performed using such holes and end faces after quenching, it is difficult to achieve the gear precision. The toothed finishing with the trimmed reference surface positioning makes the positioning accurate and reliable, and the balance distribution is relatively uniform, so as to achieve the purpose of finishing. Tooth end processing must be arranged before gear quenching, usually after hobbing (inserting) teeth.

The base hole of gear is deformed after quenching. In order to ensure the quality of tooth profile finishing, the base hole must be corrected.

The correction of the cylindrical hole gear can be used for pushing holes or grinding holes, and the pushing hole has high productivity, and is often used for unhardened gears; High precision of grinding, but low productivity. For gears with high internal hardness and high hardness after quenching, or gears with larger inner diameter and thinner thickness, it is better to use grinding holes.

When grinding holes, the gear indexing circle is usually centered, so that the radial runout of the gear ring after grinding holes is smaller, which is beneficial to later grinding or honing. In order to improve productivity, some factories have also achieved good results by replacing grinding holes with diamond boring.

The gear is a standard spur gear with a modulus m=3.5 mm, a number of teeth z=63, and a tooth shape angle a = 20 & ordm. Because it is the gear in the aircraft steam turbine, its processing accuracy is required to be high.

Because the gears in steam turbine require hard tooth surface and tough tooth center, the forged blank is selected; 40Cr is used.

(1) Main technical requirements

1) The accuracy level is set to the first tolerance group with 6 levels of accuracy, and the detected item pitch cumulative error ΔFp; The second tolerance group is level 5 accuracy, and the detection item tooth profile error Δff and the base section deviation Δfpb; The third tolerance group is level 5 accuracy, and the detected item tooth direction error ΔFβ; Measuring the tooth thickness deviation Wk by measuring the length of the normal line; Deviation code M on tooth thickness, deviation code P under tooth thickness; (In the accuracy level indication, the tooth thickness limit deviation is used to control the backlash, which is denoted by the code MP).

2) The reference depth of the reference surface of the blank is the accuracy of the IT6; There are requirements for the circular runout of the end face with the axis of the inner hole at both ends.

3) Surface roughness Ra The reference hole was 0.8 μm, the both end faces were 1.6 μm, the tooth surface was 0.8 μm, and the tooth top cylindrical surface was 3.2 μm.

(2) Forging blank is chosen to improve the mechanical properties of the material. Free forging is used in small batch production, and die forging is used in mass production.

(3) The selection of the main surface processing methods for the gear has a higher precision level. The main surface finishing methods are as follows.

Reference hole: grinding

End face: grinding

Tooth surface: hobbing - surface quenching - grinding

The general process of machining aircraft turbine spur gears:

Document Number of Parts and Components of Process Card Product Type

Product Name Gear Parts Name Total Page

No. Process Content Equipment Quantity Measuring Time Quota Remarks

1, cutting sawing machine 1

2, rough car end face, inner hole and chamfering vertical car

3, blank inspection nondestructive flaw detector

4, rough car mouth, external chamfer and face lathe

5, heat treatment (tempering) box furnace

6, fine car inner hole and end face lathe

7. Drilling: Vertical Drilling

8. Grinding large end face: surface grinder

9, reaming: drilling machine

10, pull key: slot broaching machine

11. Intermediate inspection: calipers and angle rulers

12. Make factory standard: bench bench

13, Rough Hobbing: Hobbing Machine

14. Fine Hobbing: Hobbing Machine

15. Tooth End Processing: Milling Machine

16. Cleaning: Cleaning Machine

17. Intermediate test

18, Heat Treatment (Surface Hardening): Box Furnace

19. Fine grinding inner hole: inner grinder

20, Cleaning: Cleaning Machine

21. Intermediate test

22, Matching: Inspection Machine

23, Grinding: Grinding Machine

24, Cleaning: Cleaning Machine

25, Matching: Inspection Machine

26. Write the pairing number

27, Cleaning: Cleaning Machine

28. Final test

Design proofreading approval

The gear processing process generally goes through the following stages: Blank heat treatment, tooth blank machining, tooth profile machining, tooth end machining, tooth surface heat treatment, precision benchmark correction and tooth profile finishing, etc.

The first stage of processing is the initial stage in which the blank is initially machined. Since the gear transmission accuracy is mainly determined by the tooth profile accuracy and the tooth pitch distribution uniformity, this has a direct relationship with the accuracy of the positioning reference (hole and end face) used when cutting the tooth. Therefore, this stage is mainly to prepare the fine reference for the next stage machining tooth shape, so that the accuracy of the inner hole and the end surface of the tooth basically meets the specified technical requirements. In addition to machining the benchmarks at this stage, the processing of minor surfaces other than the tooth profile should be done as late as possible in this phase.

The second stage is the processing of the tooth shape.

For gears that do not require quenching, this stage is generally the final machining stage of the gear. After this stage, gears that fully meet the requirements of the drawings should be machined. For gears that require hardening, the tooth profile accuracy required to meet the final finishing of the tooth profile must be machined at this stage, so machining at this stage is a critical stage in ensuring gear machining accuracy.

Special attention should be paid.

Tooth end processing:

A)Inverted circle

B) inverted tip

C) chamfering

Figure 1 tooth end processing

The gear end machining methods of the gear are: There are four ways of inverted circle, inverted point, chamfered edge and deburring. The gear after chamfering, chamfering and chamfering (Fig. 1). It is easy to engage when moving along the axis. Tooth end chamfering is the most widely used. Figure 2 shows the principle of finger milling cutter chamfering. When rounded, the gear rotates slowly, and the finger cutter reciprocates linearly along the gear axis while rotating at high speed. Each time the gear rotates one tooth, the milling cutter reciprocates once, and the two ends complete the tooth end rounding in relative motion. Tooth end processing should be arranged before tooth profile quenching.

Figure 2 Tooth tip circle

The third stage of processing is the heat treatment stage. At this stage, the quenching treatment of the tooth surface is mainly performed to achieve the specified hardness requirement of the tooth surface.

The final stage of machining is the finishing phase of the tooth profile.

The purpose of this stage is to correct the tooth profile deformation caused by the quenching of the gear, further improve the tooth profile accuracy and reduce the surface roughness to achieve the final accuracy requirements. In this stage, the positioning datum (hole and end face) should be trimmed first, and the inner hole and end face of the gear will be deformed after quenching. If the hole-shaped finishing is directly performed using such holes and end faces after quenching, it is difficult to achieve the gear precision. The toothed finishing with the trimmed reference surface positioning makes the positioning accurate and reliable, and the balance distribution is relatively uniform, so as to achieve the purpose of finishing. Tooth end processing must be arranged before gear quenching, usually after hobbing (inserting) teeth.

The base hole of gear is deformed after quenching. In order to ensure the quality of tooth profile finishing, the base hole must be corrected.

The correction of the cylindrical hole gear can be used for pushing holes or grinding holes, and the pushing hole has high productivity, and is often used for unhardened gears; High precision of grinding, but low productivity. For gears with high internal hardness and high hardness after quenching, or gears with larger inner diameter and thinner thickness, it is better to use grinding holes.

When grinding holes, the gear indexing circle is usually centered, so that the radial runout of the gear ring after grinding holes is smaller, which is beneficial to later grinding or honing. In order to improve productivity, some factories have also achieved good results by replacing grinding holes with diamond boring.