CNC lathe Processing 6061 Aluminum Alloy Bar

Material: 6061 Aluminum Alloy Bar φ25*50MM

Service: CNC lathe processing, roughing, fine turning, grinding

Customer: Huawei Group

Lead Time: 10 days

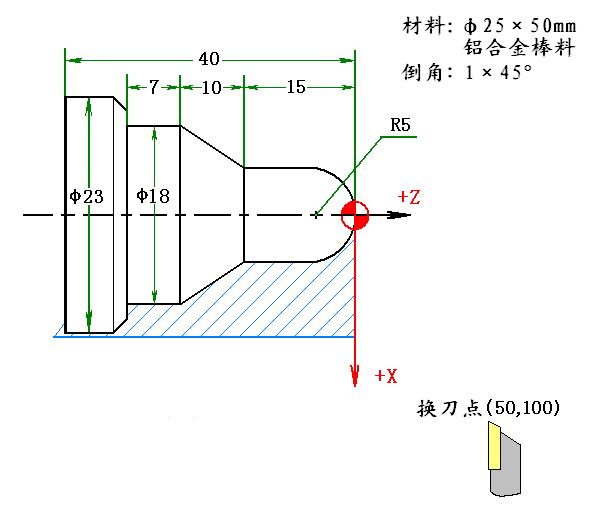

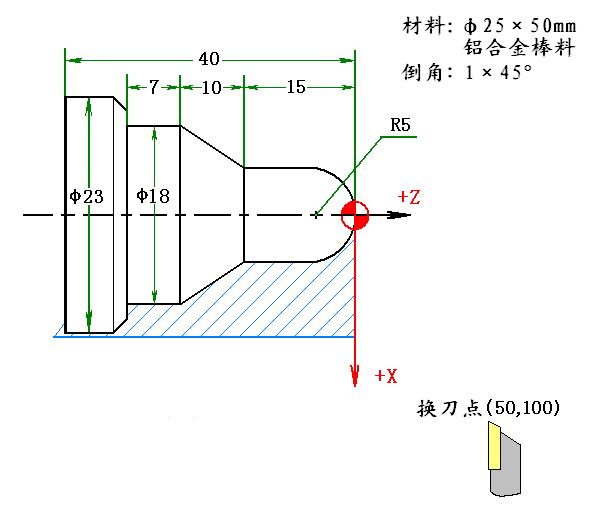

Product parts following figure:

6061 aluminum alloy electrolytic polishing fluid composition and operating conditions

Concentrated phosphoric acid (specific gravity 1.74) 70% (by weight)

YB-66 additive 30% (by weight)

Temperature 55–65°C Best 60°C

Anode current density, DA 2–8 A/dm2 (without stirring)

12–20 A/dm2 (stirring)

Voltage 10–15 volts

Polishing time 3–5 minutes

Cathode Material Lead or Stainless Steel

Cathode area: anode area 2–3:1

Service: CNC lathe processing, roughing, fine turning, grinding

Customer: Huawei Group

Lead Time: 10 days

Product parts following figure:

1, GSK-980T CNC system requires the preparation of processing procedures. Tool clamping position: Coarse, fine car with No. 1 external turning tool, Use a No. 4 cutting blade for cutting off.

| Lathe programming reference | ||

| O 1001 ; | Explain | |

| N10 | G50 X50 Z100 ; | Positioning the workpiece coordinate system with tool change points |

| N20 | M3 S560 ; | Spindle start |

| N30 | T0101 ; | Change No. 1 knife |

| N40 | G0 X25 Z2 ; | Rapidly move to the starting point of processing |

| N50 | G71 U0.8 R0.5 ; | Perform a cylindrical roughing cycle |

| N60 | G71 P70 Q140 U0.5 W0.2 F100 ; | Residual capacity X0.5 Z0.2, feed 100 mm/min |

| N70 | G0 X0 ; | Contour processing starting line |

| N80 | G1 Z0 F30 ; | Finishing feed 30 |

| N90 | G3 X10 Z-5 R5 ; | |

| N100 | G1 Z-15 ; | |

| N110 | X18 W-10 ; | |

| N120 | W-7 ; | |

| N130 | X21 ; | |

| N140 | X23 Z-33 ; | |

| N150 | Z-45 ; | Contouring the end of the line |

| N160 | G70 P70 Q140 ; | Perform a finishing cycle |

| N170 | G0 X50 Z100 ; | Back to the tool change point |

| N180 | T0404 ; | Change No. 4 cutting knife |

| N190 | G0 X27 Z-40.1 ; | Positioning cutting start point, leaving 0.1mm margin |

| N200 | G1 X12 F15 ; | |

| N210 | G0 X25 ; | |

| N220 | Z-40 ; | |

| N230 | G1 X0 F10 ; | Cut off, Feed rate 10mm/min |

| N240 | G0 X50 ; | |

| N250 | Z100 M5 ; | Replace tool point, stop spindle |

| N260 | T0100 ; | Change back to the benchmark knife |

| N270 | M30 ; | End procedure |

6061 aluminum alloy electrolytic polishing fluid composition and operating conditions

Concentrated phosphoric acid (specific gravity 1.74) 70% (by weight)

YB-66 additive 30% (by weight)

Temperature 55–65°C Best 60°C

Anode current density, DA 2–8 A/dm2 (without stirring)

12–20 A/dm2 (stirring)

Voltage 10–15 volts

Polishing time 3–5 minutes

Cathode Material Lead or Stainless Steel

Cathode area: anode area 2–3:1