Automatic Lathe Processing Stainless Steel Sphere Process Card

Stainless Steel Sphere Process Card

| Kang Ding Hardware | Automatic Lathe processing card | Product number | Part Number | Part Name | Number of pieces | page 1 | |||||

| Stainless steel ball valve | CG002 | Stainless steel sphere | 1 item | 1 page in total | |||||||

| Part processing route |

|

Part specification | |||||||||

|

workshop D-3 |

Process |

material |

304 stainless steel Φ25 round bar |

||||||||

| Treasury | Blanking | weight | 0.154kg | ||||||||

| turner | Deburring |

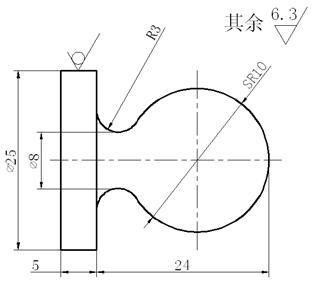

Blank material size: Φ25×34mm |

|||||||||

| turner | Rough turning | Part technical requirements | |||||||||

| turner | Finishing | 1. no burrs on the surface. | |||||||||

| turner | Deburring | ||||||||||

| Inspection room | test | ||||||||||

| No. | Step name | Device name | Equipment model | Tool number | Tool name | Process content | Unit working hours | Remarks | |||

| 1 |

Alignment Clamping |

Automatic Lathe | C6150/HK | Three-jaw chuck, chuck, tool holder wrench | Clamp the outer circle of the blank to extend 40, alignment and clamping. | 2min | |||||

| 2 | lineation | Common R arcuate knife, file, etc. | The length of scribing is 10, 20 and 24 respectively. | 2min | |||||||

| 3 | Grooving | The circular knife moves at a position of 20 to 24 long, and grooving to Φ8 | 2min | ||||||||

| 4 | Turning outer circle | Turning the front R10, turning the rear R10 | 5min |

R gauge R10 |

|||||||

| 5 | file finishing,cutting off | After smashing the spherical surface with a trowel, cut off the total length and remove burrs. | 15min | ||||||||

| 6 | test | 0~150mm vernier caliper | 5min | ||||||||

| prepared by | Zou gold hair | Review | Approve | Sign | Date of preparation | 2005.5 | |||||