Assembly Method of Thread Fasteners

Threaded fastener assembly method and assembly grading technology, according to the requirements of the actual coupling structure when tightening. Choose the most appropriate method and process, and illustrate the application of advanced assembly technology. While improving the reliability, the bolt specifications can be reduced, the coupling structure is compact, and the purpose of weight reduction and cost reduction is realized, which is of great significance in the weight reduction of automobiles.

Foreword

Thread connection is one of the four commonly used connection modes for automotive parts. Because of its simple structure, reliable connection, easy assembly, easy disassembly and good reusability, it is the most standardized mechanical part in automobile manufacturing technology and one of the more economical manufacturing methods in automobile manufacturing.

On the passenger car, the average number of thread fasteners per vehicle is about 500 kinds, 4000 PC, weighing 50kg; On commercial vehicles, the average number of threaded fasteners used per vehicle is about 7,000, weighing 88kg, of which high-strength bolts account for 1/3. The cost of threaded fasteners on an automobile accounts for about 2.5% of the cost of the whole vehicle, while the workload of threaded fasteners on assembly line accounts for 70%, which shows its importance.

Assembly method

The purpose of the threaded coupling is to reliably couple the coupled parts together by tightening the bolts/nuts. The essence of the assembly is to control the axial preload during the tightening process. The requirements for axial preload are a combination of product design and material technology. The requirement of axial preload is the comprehensive reflection of product design and material technology level.

When the threaded fastener is tightened, it is necessary to overcome the friction between the threads and the friction of the support surface. In the case of a hex head bolt, only about 10% of the energy is used to provide axial preload when tightening, and the remaining 90% of the energy is used to overcome friction. It is very difficult to directly measure and monitor the preload in the actual assembly process, and it can only be controlled indirectly.

The tightening torque, the angle of rotation and the amount of elongation have a certain relationship with the axial preload. Indirect control of the preload by controlling these parameters is the basic principle of the thread tightening technique. There are four ways to assemble a typical threaded fastener: Torque method, torque-turn angle method, yield point method, elongation method.

2.1 Torque method

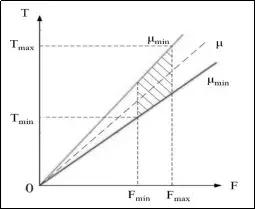

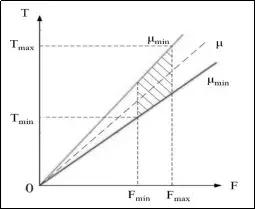

The torque method is one of the most widely used control methods. According to the basic relationship between the axial pre-tightening force of the bolt and the tightening torque, the pre-tightening force is controlled by controlling the tightening torque, which is generally used in the elastic zone. As shown in Figure 1.

figure 1 Torque method

Torque - angle method, during the tightening process. The friction coefficient has little influence on the tightening quality (only affects the stage when the fitting torque is reached, and has no effect on the angle control stage), and a relatively high pre-tightening force can be obtained, and the dispersion of the pre-tightening force is small; When tightened to the plastic zone, the bearing capacity of the bolt can be fully utilized to pick out the bolt with defective quality.

But such tightening method is complicated operation, high cost, does not apply to the short bolt small angle; Because of the large pre-tightening force (especially tightening to the plastic zone), the applicability of bolts with poor plasticity and repeated use should be considered.

2.3 Yield point method

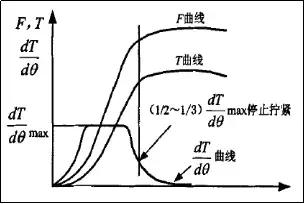

Yield-point method, also known as torque slope method. By monitoring the slope of the tightening process screwing torque versus angle curve, the screw is screwed tight to the method of the yield point.

During the tightening process, the tightening curve changes from the elastic zone to the plastic zone, and the linear relationship between torque and angle changes, and the slope also changes. When the change in slope reaches a certain range, it is considered to reach the yield point, as shown in Figure 3.

Figure 3 yield point method

The tightening quality (pre-tightening force dispersion) of yield point method is only related to the yield strength of bolts, and is not affected by friction coefficient and the starting point of rotation angle, so the assembly accuracy can be improved. The ability to maximize the bolt is achieved by tightening the bolt to its yield point.

The disadvantage is that an automatic tightening machine with an arithmetic function is needed, the control system is complicated, the price is high, the material, structure and heat treatment of the bolt are very high, and it is generally applied to a mounting part requiring relatively high.

2.4 elongation method

Elongation method, with ultrasonic or other means micrometer, measured during tightening or screwing elongated length immediately after the end of the bolt. A method of controlling the axial preload force by using the relationship between the preload force and the amount of change in the length of the bolt. In the range of elastic deformation, the axial preload force is related to the force cross-sectional area, elongation and strength of the bolt, namely:

In the formula:

δb: elongation,

F: axial preload,

Cb: bolt stiffness,

Le: the effective length of the bolt,

Eb: bolt elastic modulus,

Ab: Bolt cross-sectional area.

After the strength grade and size of the bolt are determined, the pre-tightening force is only related to the bolt elongation, which can eliminate the influence of variable factors such as friction coefficient, contact deformation and deformation of the joint.

Therefore, the highest control accuracy can be obtained and used as a preload control method for important bolted joints.

However, measuring devices (such as micrometers, ultrasonic waves, etc.) are inconvenient to implement on a specific joint structure and affect the production cycle, so they have not been widely used in the automotive industry. Under laboratory conditions, the elongation method is an indispensable means for calibration, calibration, and experimental development.

The four methods of assembly of threaded joints have their own advantages and disadvantages. When tightening, it should be determined according to the actual joint structure. To determine the requirements of the connected parts, the accuracy requirements of the axial preload and the application of the control method, the most suitable method is selected through experiment and analysis.

Foreword

Thread connection is one of the four commonly used connection modes for automotive parts. Because of its simple structure, reliable connection, easy assembly, easy disassembly and good reusability, it is the most standardized mechanical part in automobile manufacturing technology and one of the more economical manufacturing methods in automobile manufacturing.

On the passenger car, the average number of thread fasteners per vehicle is about 500 kinds, 4000 PC, weighing 50kg; On commercial vehicles, the average number of threaded fasteners used per vehicle is about 7,000, weighing 88kg, of which high-strength bolts account for 1/3. The cost of threaded fasteners on an automobile accounts for about 2.5% of the cost of the whole vehicle, while the workload of threaded fasteners on assembly line accounts for 70%, which shows its importance.

Assembly method

The purpose of the threaded coupling is to reliably couple the coupled parts together by tightening the bolts/nuts. The essence of the assembly is to control the axial preload during the tightening process. The requirements for axial preload are a combination of product design and material technology. The requirement of axial preload is the comprehensive reflection of product design and material technology level.

When the threaded fastener is tightened, it is necessary to overcome the friction between the threads and the friction of the support surface. In the case of a hex head bolt, only about 10% of the energy is used to provide axial preload when tightening, and the remaining 90% of the energy is used to overcome friction. It is very difficult to directly measure and monitor the preload in the actual assembly process, and it can only be controlled indirectly.

The tightening torque, the angle of rotation and the amount of elongation have a certain relationship with the axial preload. Indirect control of the preload by controlling these parameters is the basic principle of the thread tightening technique. There are four ways to assemble a typical threaded fastener: Torque method, torque-turn angle method, yield point method, elongation method.

2.1 Torque method

The torque method is one of the most widely used control methods. According to the basic relationship between the axial pre-tightening force of the bolt and the tightening torque, the pre-tightening force is controlled by controlling the tightening torque, which is generally used in the elastic zone. As shown in Figure 1.

figure 1 Torque method

The relationship between the tightening torque T and the axial preload force F is:

In the formula, T: tighten the torque, F: axial preload, P: pitch, α: flank angle, D2: thread diameter, dW: equivalent friction diameter of the support surface, μS: thread friction coefficient, μW: friction coefficient of the bearing surface.

When assembled by the torque method, due to the influence of the friction coefficient, the axial preload force fluctuates greatly, and the material potential is not fully utilized, and the bolt strength utilization rate is low. However, because it is simple to operate, low in cost, and effective for most threaded joints, it is still the most commonly used assembly method.

2.2 Torque-turn angle method

In the formula, T: tighten the torque, F: axial preload, P: pitch, α: flank angle, D2: thread diameter, dW: equivalent friction diameter of the support surface, μS: thread friction coefficient, μW: friction coefficient of the bearing surface.

When assembled by the torque method, due to the influence of the friction coefficient, the axial preload force fluctuates greatly, and the material potential is not fully utilized, and the bolt strength utilization rate is low. However, because it is simple to operate, low in cost, and effective for most threaded joints, it is still the most commonly used assembly method.

2.2 Torque-turn angle method

Torque-turn angle method: After the specified initial torque (i.e. the fit torque) is reached when the screw is tightened, the threaded parts are rotated to the specified angle. This method produces a certain axial elongation of the bolt based on a certain angular displacement and is compressed by the coupling member, resulting in a certain preload. The angle of rotation needs to be obtained by calculation or experiment in advance.

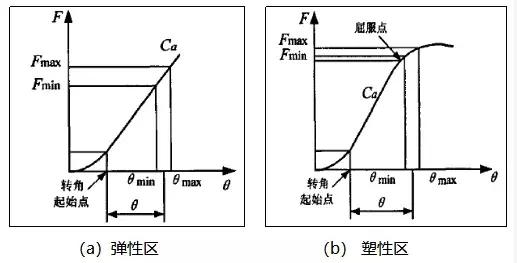

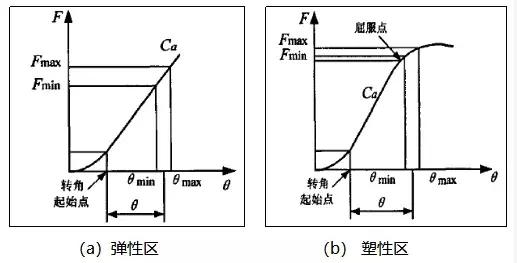

There are two commonly used torque-turn angle methods, one is to tighten the threaded fastener to the elastic zone. As shown in Figure 2a, the relationship between the corner and the axial preload is as follows:

In the formula: θ: corner, F: axial preload, P: pitch, C1: bolt stiffness, C2: stiffness of the coupled part. The axial preload of the bolt is related to the stiffness of the system.

The other is that the threaded coupling is tightened above the yield point, ie the plastic zone. As shown in Figure 2b, the axial preload force is related to the strength of the bolt.

There are two commonly used torque-turn angle methods, one is to tighten the threaded fastener to the elastic zone. As shown in Figure 2a, the relationship between the corner and the axial preload is as follows:

In the formula: θ: corner, F: axial preload, P: pitch, C1: bolt stiffness, C2: stiffness of the coupled part. The axial preload of the bolt is related to the stiffness of the system.

The other is that the threaded coupling is tightened above the yield point, ie the plastic zone. As shown in Figure 2b, the axial preload force is related to the strength of the bolt.

figure 2 Relationship between rotation angle and preload

Torque - angle method, during the tightening process. The friction coefficient has little influence on the tightening quality (only affects the stage when the fitting torque is reached, and has no effect on the angle control stage), and a relatively high pre-tightening force can be obtained, and the dispersion of the pre-tightening force is small; When tightened to the plastic zone, the bearing capacity of the bolt can be fully utilized to pick out the bolt with defective quality.

But such tightening method is complicated operation, high cost, does not apply to the short bolt small angle; Because of the large pre-tightening force (especially tightening to the plastic zone), the applicability of bolts with poor plasticity and repeated use should be considered.

2.3 Yield point method

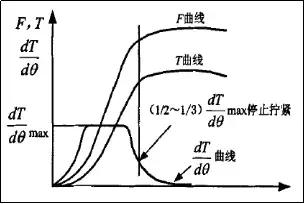

Yield-point method, also known as torque slope method. By monitoring the slope of the tightening process screwing torque versus angle curve, the screw is screwed tight to the method of the yield point.

During the tightening process, the tightening curve changes from the elastic zone to the plastic zone, and the linear relationship between torque and angle changes, and the slope also changes. When the change in slope reaches a certain range, it is considered to reach the yield point, as shown in Figure 3.

Figure 3 yield point method

The tightening quality (pre-tightening force dispersion) of yield point method is only related to the yield strength of bolts, and is not affected by friction coefficient and the starting point of rotation angle, so the assembly accuracy can be improved. The ability to maximize the bolt is achieved by tightening the bolt to its yield point.

The disadvantage is that an automatic tightening machine with an arithmetic function is needed, the control system is complicated, the price is high, the material, structure and heat treatment of the bolt are very high, and it is generally applied to a mounting part requiring relatively high.

2.4 elongation method

Elongation method, with ultrasonic or other means micrometer, measured during tightening or screwing elongated length immediately after the end of the bolt. A method of controlling the axial preload force by using the relationship between the preload force and the amount of change in the length of the bolt. In the range of elastic deformation, the axial preload force is related to the force cross-sectional area, elongation and strength of the bolt, namely:

In the formula:

δb: elongation,

F: axial preload,

Cb: bolt stiffness,

Le: the effective length of the bolt,

Eb: bolt elastic modulus,

Ab: Bolt cross-sectional area.

After the strength grade and size of the bolt are determined, the pre-tightening force is only related to the bolt elongation, which can eliminate the influence of variable factors such as friction coefficient, contact deformation and deformation of the joint.

Therefore, the highest control accuracy can be obtained and used as a preload control method for important bolted joints.

However, measuring devices (such as micrometers, ultrasonic waves, etc.) are inconvenient to implement on a specific joint structure and affect the production cycle, so they have not been widely used in the automotive industry. Under laboratory conditions, the elongation method is an indispensable means for calibration, calibration, and experimental development.

The four methods of assembly of threaded joints have their own advantages and disadvantages. When tightening, it should be determined according to the actual joint structure. To determine the requirements of the connected parts, the accuracy requirements of the axial preload and the application of the control method, the most suitable method is selected through experiment and analysis.