Four Applications of Industrial Robots and CNC Machine Tools

REVIEW: the automotive industry in the past has been the most important areas of robotics applications, With the increase of automation requirements, industrial robot applications have been further expanded, in addition to traditional welding applications. Robots have also been widely used in the fields of machine loading and unloading, material handling, palletizing, grinding, painting, and assembly.

Metal forming machine tools are an important part of machine tools. Forming and processing are often associated with high labor intensity, noise pollution, metal dust, etc. Sometimes it is in a high temperature, high humidity, or even a polluted environment. The work is simple and boring, and it is difficult for companies to recruit people. The integration of industrial robots and forming machine tools not only solves the problem of enterprise employment, but also improves processing efficiency and safety, and improves machining accuracy. It has great room for development.

CNC Bending Machine and Robot Integrated Application

There are two main ways to integrate robot bending machines.

One is the bending machine as the center, the robot configuration vacuum suction cup, magnetic tension sheet loading rack, positioning table, cutting table, flip frame forming bending unit.

The second is the flexible processing line formed by robots and laser equipment or CNC rotary table punching machines, industrial robot walking shafts, sheet material transmission lines, positioning tables, and vacuum suction cups. Eston uses its own technology and platform in the robot control system and machine tool control system to realize seamless connection, develop bending software packages, and implement closed-loop control of robot feeding during bending. At different bending speeds, the robot performs full tracking of automatic matching. The bending software package also shortens the bending teaching time from 2-3 days to 2-3 hours. In the switch cabinet, file cabinets, elevators, security doors and other processing is well applied.

Stamping presses and robot integration application

Stamping presses and robot integration application

There are two main methods for the integration of robot and press stamping.

The first is a single robot punching and loading and unloading: The metal sheet is transferred from the demounting table to the positioning table by the robot, and then transferred to the press mold for stamping. After the stamping is completed, the robot takes the material and puts it into the stacking table, so that a single press robot can automatically load and unload.

The second is the robot stamping connection: through multiple robots, a stamping connection is established between multiple presses. According to the requirements of the forming process of the workpiece, multiple presses are required to be processed. The entire production line is composed of a demolition robot, a feeding robot, a transfer robot between presses, and a tail line robot. Compared with robots with linear coordinates, the use of industrial robots is more flexible, there is no contour requirement for the mold, and it is easy to integrate. Eston seamlessly uses the autonomous press control system and the robot control system to achieve the optimal coordination of robot movements and presses. The use of fieldbus maximizes the efficiency of the entire production line and increases safety.

Hot Die Forging and Robotic Integrated Applications

Hot Die Forging and Robotic Integrated Applications

Hot die forging production lines usually consist of two die forging presses, one for stamping and the other for trimming. The hot die forging robot integrated application usually configures two robots, one is responsible for transferring the high-temperature material processed by the intermediate frequency furnace to the press forming die forging press, and the other is responsible for taking the material from the press forming die forging press and transferring it to another die. Forging machine for trimming. In order to prevent high-temperature stamping parts from sticking to the mold, it is necessary to lubricate the mold after each stamping. Lubrication can be done by robots or by special agencies. Due to the high temperature and humidity and the harsh environment caused by graphite lubrication, special attention should be paid to the protection of the robot and the ability of the robot to resist heat radiation. Eston’s robot has a 4-5-6 axis motor at the robot arm and arm joints. It has the structure characteristic of self - far away from thermal radiation. The electronic cam control system is installed in the forging press to coordinate the operation of the forging press and the operation of the robot to improve the processing efficiency and enhance the safety of the system.

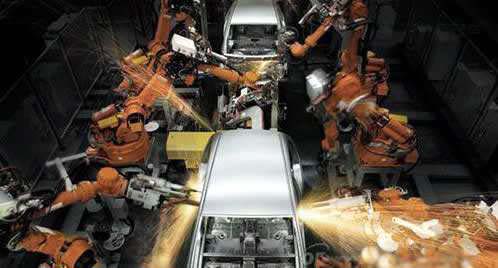

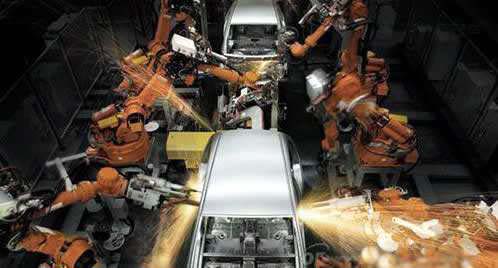

Welding robot application

Welding is the process after the forming machine tool plate is processed. There are two types of robot welding: resistance welding and arc welding.

Welding robot applications account for more than 40% of robots. Arc welding application is based on the robot, configuration welding machine, wire feeder, welding gun, fixtures and other components composed of welding workstations. Eston offers 6kg dedicated arc welding robot workstations with arm lengths of 1400, 1600 and 2000mm.

Resistance welding application is based on the robot as the core, configuration spot welding gun, welding controller, water and gas unit, pipeline package, fixtures and other components composed of welding workstations. Eston offers a 220kg special resistance welding robot workstation with an arm length of 2600mm. In addition, Estonia Automation develops a special welding software package for welding applications and integrates a welding expert process parameter library into a robot system to meet various types of needs.

Metal forming machine tools are an important part of machine tools. Forming and processing are often associated with high labor intensity, noise pollution, metal dust, etc. Sometimes it is in a high temperature, high humidity, or even a polluted environment. The work is simple and boring, and it is difficult for companies to recruit people. The integration of industrial robots and forming machine tools not only solves the problem of enterprise employment, but also improves processing efficiency and safety, and improves machining accuracy. It has great room for development.

CNC Bending Machine and Robot Integrated Application

There are two main ways to integrate robot bending machines.

One is the bending machine as the center, the robot configuration vacuum suction cup, magnetic tension sheet loading rack, positioning table, cutting table, flip frame forming bending unit.

The second is the flexible processing line formed by robots and laser equipment or CNC rotary table punching machines, industrial robot walking shafts, sheet material transmission lines, positioning tables, and vacuum suction cups. Eston uses its own technology and platform in the robot control system and machine tool control system to realize seamless connection, develop bending software packages, and implement closed-loop control of robot feeding during bending. At different bending speeds, the robot performs full tracking of automatic matching. The bending software package also shortens the bending teaching time from 2-3 days to 2-3 hours. In the switch cabinet, file cabinets, elevators, security doors and other processing is well applied.

There are two main methods for the integration of robot and press stamping.

The first is a single robot punching and loading and unloading: The metal sheet is transferred from the demounting table to the positioning table by the robot, and then transferred to the press mold for stamping. After the stamping is completed, the robot takes the material and puts it into the stacking table, so that a single press robot can automatically load and unload.

The second is the robot stamping connection: through multiple robots, a stamping connection is established between multiple presses. According to the requirements of the forming process of the workpiece, multiple presses are required to be processed. The entire production line is composed of a demolition robot, a feeding robot, a transfer robot between presses, and a tail line robot. Compared with robots with linear coordinates, the use of industrial robots is more flexible, there is no contour requirement for the mold, and it is easy to integrate. Eston seamlessly uses the autonomous press control system and the robot control system to achieve the optimal coordination of robot movements and presses. The use of fieldbus maximizes the efficiency of the entire production line and increases safety.

Hot die forging production lines usually consist of two die forging presses, one for stamping and the other for trimming. The hot die forging robot integrated application usually configures two robots, one is responsible for transferring the high-temperature material processed by the intermediate frequency furnace to the press forming die forging press, and the other is responsible for taking the material from the press forming die forging press and transferring it to another die. Forging machine for trimming. In order to prevent high-temperature stamping parts from sticking to the mold, it is necessary to lubricate the mold after each stamping. Lubrication can be done by robots or by special agencies. Due to the high temperature and humidity and the harsh environment caused by graphite lubrication, special attention should be paid to the protection of the robot and the ability of the robot to resist heat radiation. Eston’s robot has a 4-5-6 axis motor at the robot arm and arm joints. It has the structure characteristic of self - far away from thermal radiation. The electronic cam control system is installed in the forging press to coordinate the operation of the forging press and the operation of the robot to improve the processing efficiency and enhance the safety of the system.

Welding robot application

Welding is the process after the forming machine tool plate is processed. There are two types of robot welding: resistance welding and arc welding.

Welding robot applications account for more than 40% of robots. Arc welding application is based on the robot, configuration welding machine, wire feeder, welding gun, fixtures and other components composed of welding workstations. Eston offers 6kg dedicated arc welding robot workstations with arm lengths of 1400, 1600 and 2000mm.

Resistance welding application is based on the robot as the core, configuration spot welding gun, welding controller, water and gas unit, pipeline package, fixtures and other components composed of welding workstations. Eston offers a 220kg special resistance welding robot workstation with an arm length of 2600mm. In addition, Estonia Automation develops a special welding software package for welding applications and integrates a welding expert process parameter library into a robot system to meet various types of needs.