Stainless Steel, Titanium Alloy Micro Deep Hole Processing Technology and Case

Micropore processing of stainless steel and titanium alloy is a difficult technology in traditional processing, which is between traditional processing and micro-processing. Research in this area is available in research laboratories in many countries. Although laser can be used to process small diameter holes, if laser is used, it will be a trumpet-like micro-hole. There are many residues.

EDM is a good choice, with a minimum of 0.15mm diameter micropores. However, the microporous wall will leave a recast layer, which will affect the service life of the micropores, and the surface quality of the pore walls of the micropores will deteriorate.

With mechanical drilling: 1, the drill bit is very easy to break. 2, there will be burrs at the exit of the micropores, this burr will affect the use of the effect.

We have been engaged in the etching process for microporous processing for more than 10 years, and have accumulated a little experience in processing micropores. Micropores processed by our company: The minimum aperture is 80um, the hole wall roughness is 0.02, the depth is 1mm, and there is no burr.

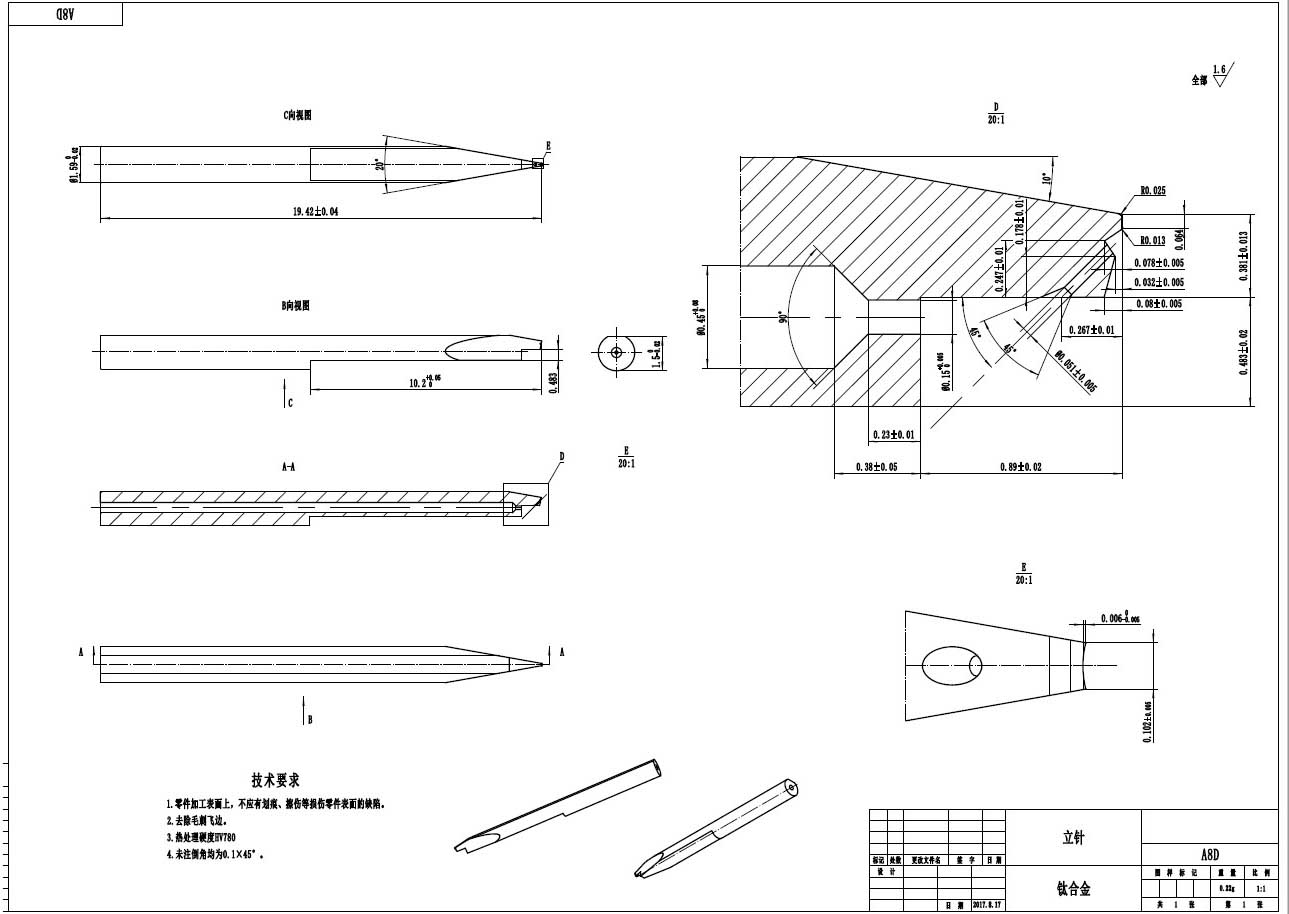

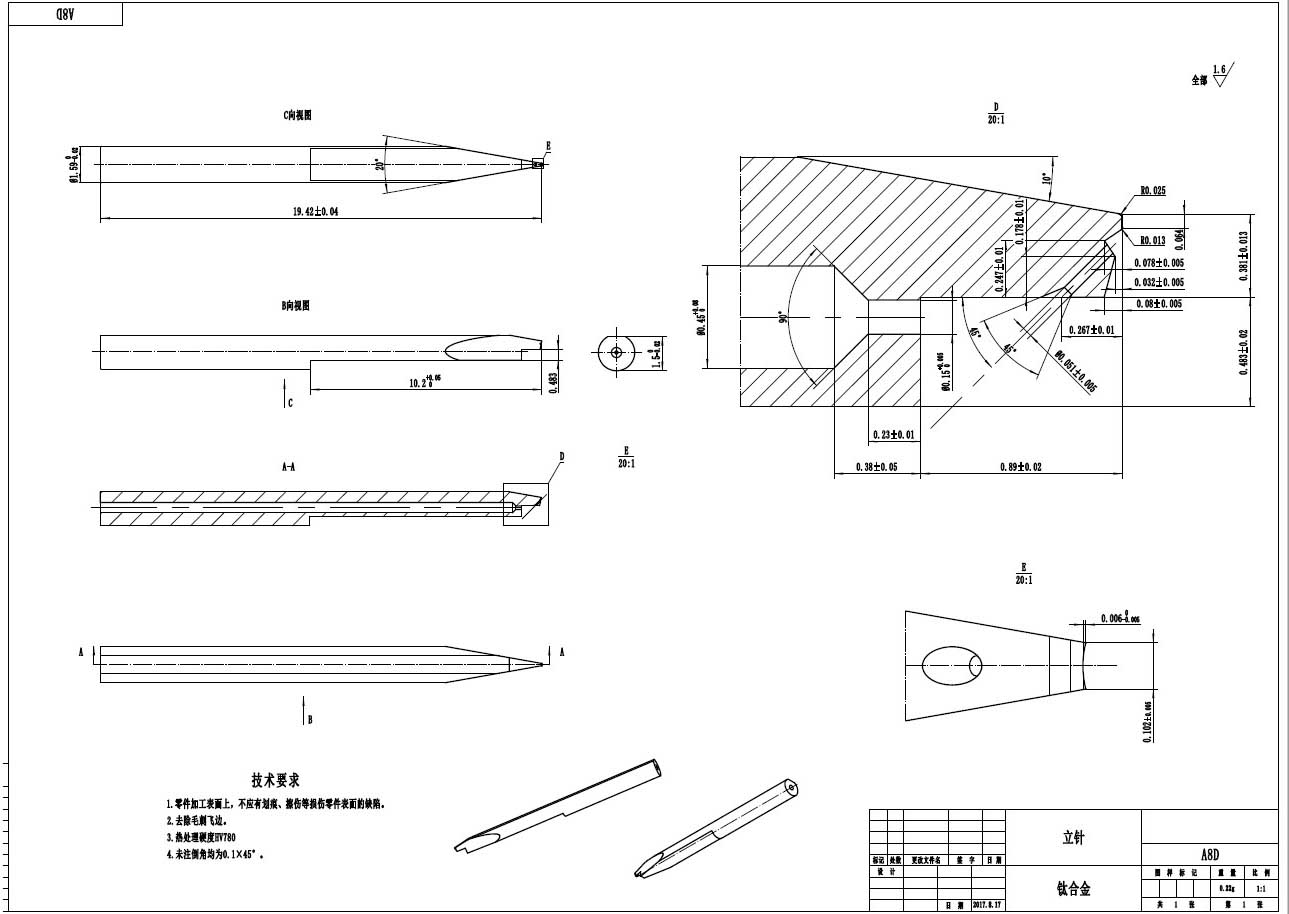

Titanium alloy vertical needle deep hole processing technology

EDM is a good choice, with a minimum of 0.15mm diameter micropores. However, the microporous wall will leave a recast layer, which will affect the service life of the micropores, and the surface quality of the pore walls of the micropores will deteriorate.

With mechanical drilling: 1, the drill bit is very easy to break. 2, there will be burrs at the exit of the micropores, this burr will affect the use of the effect.

We have been engaged in the etching process for microporous processing for more than 10 years, and have accumulated a little experience in processing micropores. Micropores processed by our company: The minimum aperture is 80um, the hole wall roughness is 0.02, the depth is 1mm, and there is no burr.

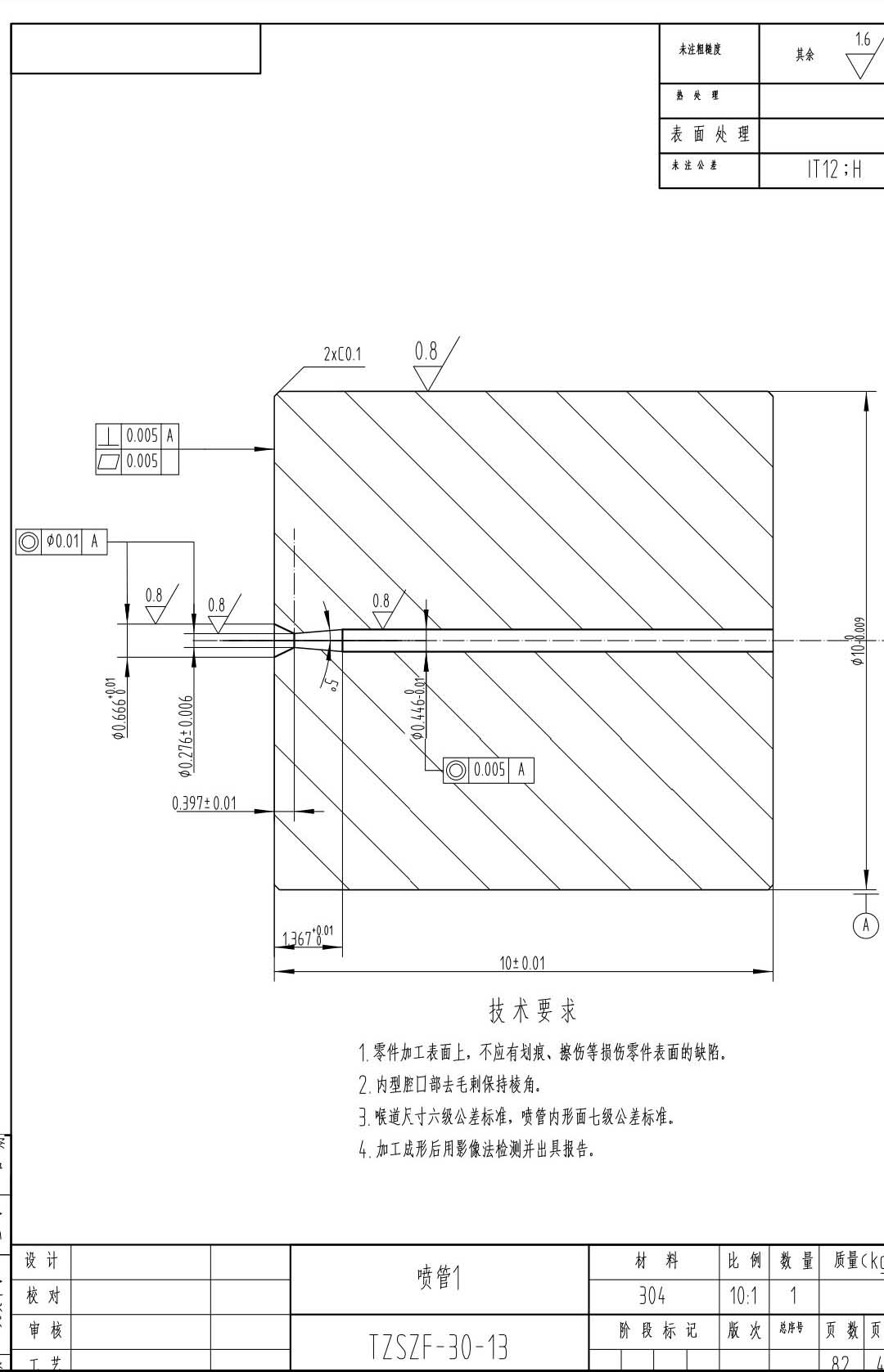

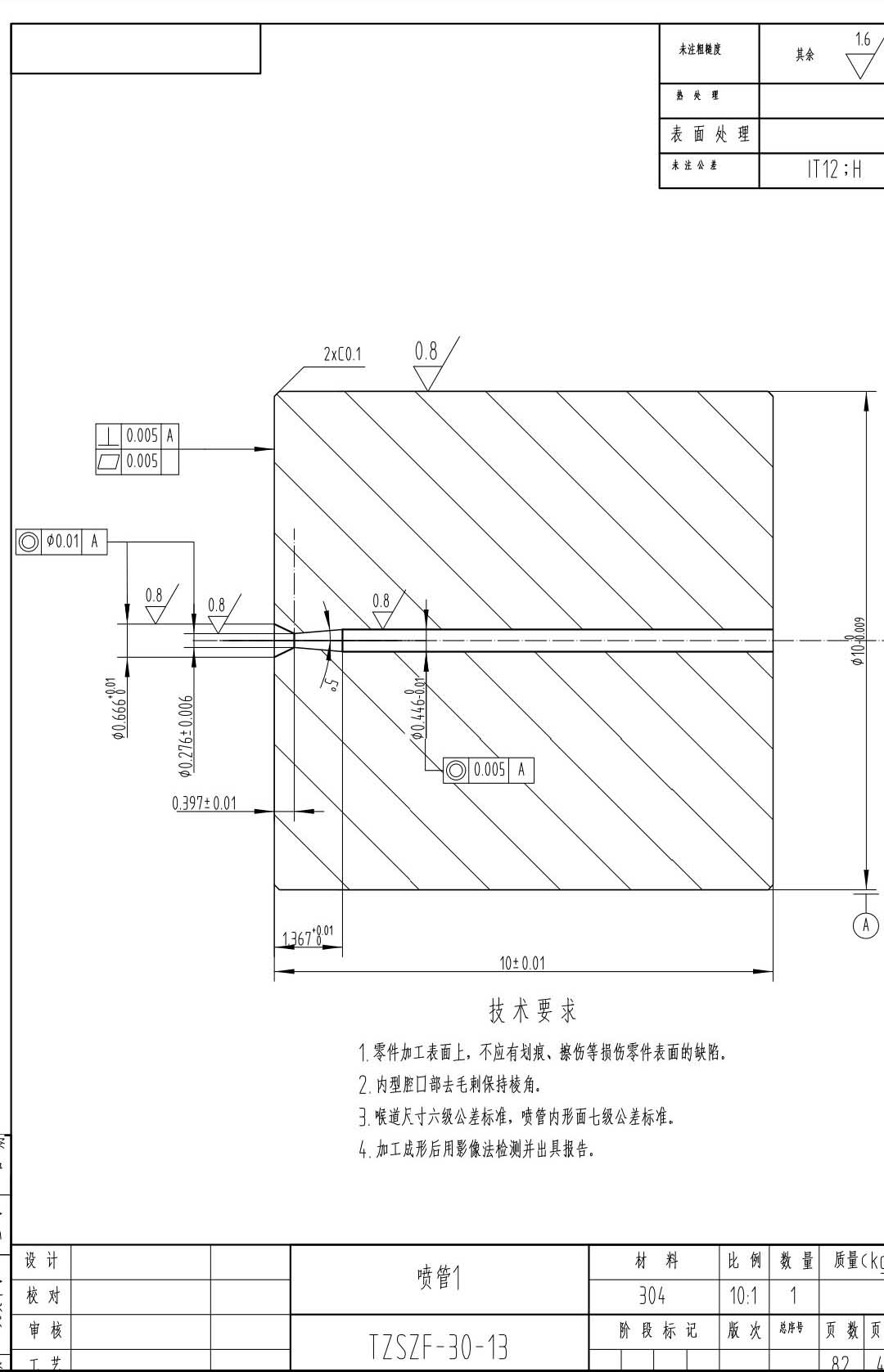

| product description | |

| product name: | Stainless steel, titanium alloy micropore processing |

| Material material:: | SUS304 stainless steel, 316, TC4, titanium alloy |

| Material thickness (metric): | 0.03,0.05,0.08,0.1,0.12,0.15,0.2mm-1mm |

| Product Usage: | Stainless steel micro-hole processing is mainly processed by etching process, and is applied to high-end precision parts products such as precision electronics and automobiles. |

| Features: | Stainless steel etching, micro-pore diameter, uniform line, no hair, no gap |

| product price:: | Comprehensive verification of material quality, thickness, accuracy requirement and quantity of production |

| Etching processing capability: | Use roll-to-roll exposure machine for mass production and up to 1000 square meters per day |

| Samples are provided: | Paid proofing, sample within 3 days, the fastest 24 hours to sample, large quantities can apply for free samples |

| Batch production time: | 7 days |

| Product testing and after-sales: | Secondary element, imager |

| Product etching characteristics | |

| 1. Micro-hole processing is lower than the mold cost, and can be arbitrarily changed according to the design requirements of the designer. The cost is lower than the hardware mold by a hundred times! | |

| 2, can achieve half of the metal, increase the company LOGO, achieve brand health | |

| 3, extremely high precision, up to +/-0.0075mm precision, to meet the assembly requirements of different products | |

| 4, complex shape micro-hole processing products can also be etched without additional cost | |

| 5, no burrs, pressure points, the product does not deform, does not change the nature of the material, does not affect the function of the product | |

| 6, thick and thin materials can be processed the same to meet the requirements of different assembly components | |

| 7, almost all metals can be etched, no restrictions on the design of various patterns | |

| 8. Manufacturing of metal parts that cannot be completed by various types of machining | |

Titanium alloy vertical needle deep hole processing technology