Titanium alloy milling deep groove processing

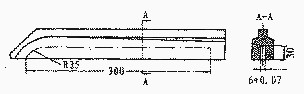

For a titanium alloy part, a machining example of a deep groove with a width of 4 mm, a depth of 30 mm, and a length of 300 mm is processed (Fig. 1). Titanium alloy has a small elastic modulus and a small thermal conductivity coefficient, which is a typical difficult-to-machine material, especially for deep groove cutting.

figure 1 Titanium deep groove parts

For ordinary materials (such as 45 steel), the deep groove is usually milled with high speed steel (W18Cr4V) saw blade milling cutter (φ120×φ40×4, 60 teeth) and fully cooled to obtain good milling results. However, for the titanium alloy TC4 material, when the above-mentioned saw blade milling cutter cuts a blind groove with a depth of 30 mm, a new blade wears the first to second workpieces, and the cutting edge becomes dull. If the sharpening is not performed in time, the extrusion in front of the cutting edge will increase significantly, and the metal deformation in the cutting zone will also increase. At the same time, the back angle of the tool after wear is continuously reduced, thereby increasing the friction between the back of the tool and the machined surface, so that the cutting heat is increased, resulting in a sharp rise in the cutting temperature. When the third part was machined, the tips on both sides of the cutter teeth were obviously burned out, especially the titanium scraps were stuck in the back of the cutter and the chip pocket, indicating that severe crushing occurred during the cutting process. This is because, in addition to the small thermal conductivity coefficient of the titanium alloy, the friction coefficient of the titanium alloy material and the tool material is greatly increased, the cutting temperature is rapidly increased, and the chip removal is difficult due to the insufficient size of the chip pocket. If the above-mentioned worn blade is sharpened, the burnt blade tip should be completely ground out, and the blade diameter should be ground by 3 to 4 mm. In this way, the number of sharpening of a tool is greatly reduced, making the chip pocket of the tooth smaller. Practice has shown that after such a sharpened blade, only one part can be processed. To this end, in the study, the new blade was tried to jump to increase the chip space of the milling cutter. It was found that this method can increase the life of the tool by about 3 times, and each blade can process 5 parts. This kind of tool can meet the needs of scientific research and trial production, but it can not meet the requirements of mass production.

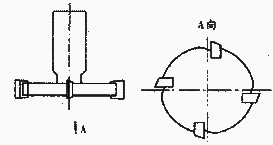

We use the sawtooth milling cutter to modify the tooth skipping, which can significantly improve the life of the saw blade milling cutter for milling titanium alloy TC4. This method reduces the friction between the tool and the titanium alloy material and increases the chip space, but the potential of this method is limited. From the perspective of production efficiency and cost, cemented carbide (YG15) welding tools and high-speed steel (W6Mo5Cr4V2Al) welding tools should be designed. The tool structure is shown in Figure 2.

figure 2 As shown in Fig. 2, the rake angle of the cutter is 6° to 8°, the relief angle is 6°, and the back rake angle is 3° to 5°.

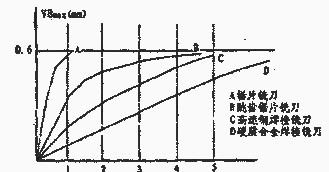

The grooving of the above workpiece was tested with a cemented carbide welding tool and a high speed steel welding tool (the cutting conditions were the same). High-speed steel welding tools can process six parts, while YD15 welding tools can process 30 parts. The integrated saw blade milling cutter and the skip tooth saw blade milling cutter were tested under the conditions of cutting amount of ap=7 mm, f=0.3 mm/r, and v=26 m/min. The relationship between tool wear and the number of slots is shown (see Figure 3).

image 3 Comparison of different material tools in milling deep groove of titanium alloy

As can be seen from Figure 3. In deep groove milling of titanium alloys, the wear of the tool is mainly related to the tool material. For the difficult-to-machine materials of titanium alloy, fine-grained hard alloy materials should be preferred, which greatly improves the processing efficiency and processing quality. In addition, the structure of the cutting part of the tool is also very important, considering that the tooth has a large chip space, and it is necessary to consider a reasonable number of teeth to improve the processing efficiency. Therefore, we use 4- or 6-tooth hard alloy welded slot milling cutters to meet the requirements of titanium alloy deep groove batch processing.

Tests show that for deep groove milling of titanium alloys, the tool life of the tooth saw blade milling cutter is increased by 3 times compared with the conventional saw blade milling cutter; The YD15 carbide welding cutter can significantly improve tool life.

Tests show that for deep groove milling of titanium alloys, the tool life of the tooth saw blade milling cutter is increased by 3 times compared with the conventional saw blade milling cutter; The YD15 carbide welding cutter can significantly improve tool life.