Spool hole machining of automotive gearbox

The processing of the valve block of the automatic transmission valve body of the automobile is the most demanding position in the entire machining process of the box hole. It is used in the processing of aluminum alloy valve bodies with a common silicon content of 8% to 16%. The tooling scheme commonly used by UNIMERCO is a combination of two roughing and one finishing.

First, reaming rough machining

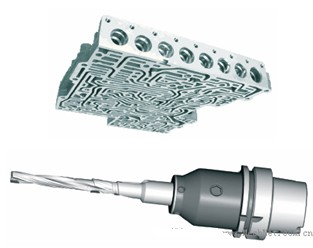

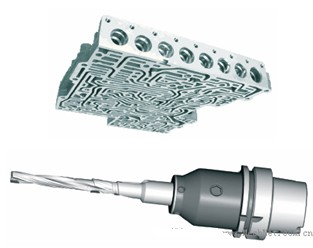

The UM PCD straight slot reaming knife is used, as shown in Figure 1. The processing speed is n=8000r/min, and the feed rate Fn=0.3mm/min.

Figure 1 roughing tool and workpiece section

The main features of the reaming tool:

1. Good at processing with interference holes;

2, the light repair and guiding is very good, thus ensuring high roundness, cylindricity, and smoothness requirements;

3, with excellent deburring function, basically does not require a special follow-up deburring process;

4. The processing efficiency is usually 3 to 8 times that of the straight groove cutter, which directly reduces the equipment and personnel cost of the customer.

two, Reaming finishing

The UM PCD spiral groove reamer is used, as shown in Figure 5. The processing speed is n=10000r/min, and the feed rate Fn=0.5mm/min.

figure 2 Finishing reaming tool and workpiece picture

The processing scheme of “one rough machining and one finishing machining” is adopted. The machined surface of the workpiece has a very good mirror effect, and the surface roughness Ra can be achieved from 0.08 to 0.20. Moreover, the tool life can be stabilized up to 80,000 holes before grinding.

First, reaming rough machining

The UM PCD straight slot reaming knife is used, as shown in Figure 1. The processing speed is n=8000r/min, and the feed rate Fn=0.3mm/min.

Figure 1 roughing tool and workpiece section

1. Good at processing with interference holes;

2, the light repair and guiding is very good, thus ensuring high roundness, cylindricity, and smoothness requirements;

3, with excellent deburring function, basically does not require a special follow-up deburring process;

4. The processing efficiency is usually 3 to 8 times that of the straight groove cutter, which directly reduces the equipment and personnel cost of the customer.

two, Reaming finishing

The UM PCD spiral groove reamer is used, as shown in Figure 5. The processing speed is n=10000r/min, and the feed rate Fn=0.5mm/min.

figure 2 Finishing reaming tool and workpiece picture