Sheet Metal Processing Technology Explained

Course content:

1. Definition

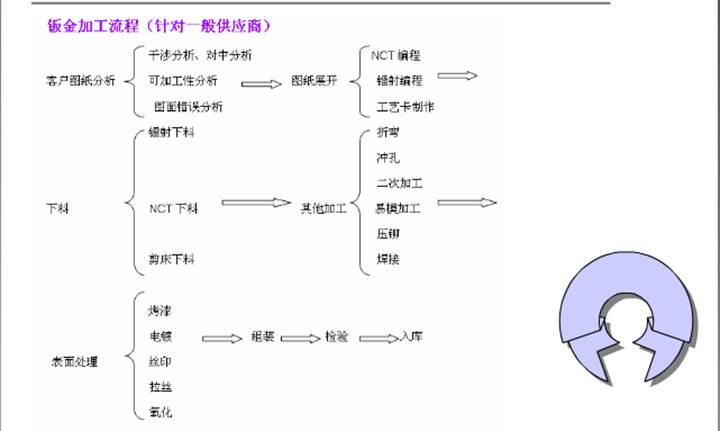

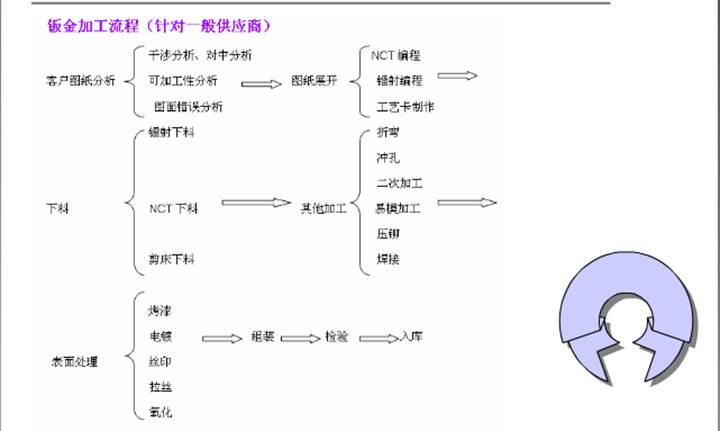

2. Processing process introduction

3. Introduction to processing methods

4. Industry processing capacity introduction

Definition of sheet metal processing

Definition of sheet metal processing

Sheet metal processing is a comprehensive cold-working process for sheet metal (usually below 6mm), including shearing, blanking, bending, welding, riveting, molding and surface treatment. Its distinguishing feature is the uniform thickness of the same parts. According to different processing methods, they are generally divided into two categories:

1. Non-mold processing:

Through NCT (CNC punching), laser (laser cutting machine), CNC bending machine tools, rivets and other processing tools on the processing of sheet metal technology, generally used for rapid prototype production, higher cost.

2. Mold processing:

Through a fixed mold, the sheet metal is processed. Generally, there are blanking molds and forming molds, which are mainly used for mass production and have a low cost.

Common processing methods are introduced:

1. NCT (Numerical Control Machine) Processing

2. Laser (laser cutting) processing

3. Folding machine

4. pliers machine

5. Mold processing

6. Surface treatment

7. Sheet metal connection

Machining principle of NC machine tool:

CNC machine tools are flexible automatic machine tools that can adapt to frequent changes in products. The various operations and steps required for the machining process and the relative displacements between the tool and the workpiece are represented by digitized codes.The digital information is sent to a dedicated or general-purpose calculator via a control medium (such as a paper tape or a disk), and the calculator processes and calculates the input information. Various commands are issued to control the machine's servo system or other execution components so that the machine tool automatically processes the desired workpiece or product.

Common uses of CNC machine tools:

Unloading, punching mesh holes, punching bumps, trimming edges, bumps, pressing ribs, pressing lines, pumping holes.

(Pressing line is a kind of a variety of post-press processing methods, such as hot stamping, convex-concave, embossing, laminating, pressure lines, sticking, cutting, etc. are all postpress processing.

The minimum distance between two pressure lines is generally 3mm, but it also varies slightly depending on the processing object. ), CNC machine tool machining accuracy: +/- 0.1mm

NCT (Numerical Control Punch) processing process and precautions:

1. When the distance from the edge is less than the material thickness, Punching hole will cause the edge to turn up. Square hole is bigger and more obvious, usually considering LASER (laser cutting) two times cutting.

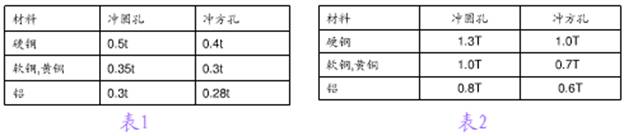

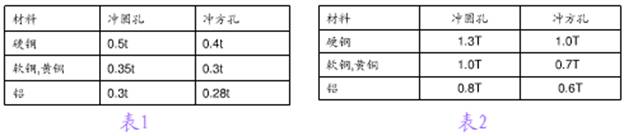

2. The distance between the hole and the edge of the NCT punching hole should not be too small. Its allowable value is shown in Table 1. The minimum hole diameter for the NCT punching is shown in Table 2:

3. Drawing hole:

The minimum distance from the edge of the NCT drawing hole is 3T. The minimum distance between the two drawing holes is 6T. The minimum safety distance from the punching edge (inside) is 3T+R. If it is too small, it must be handled by the pressure line.

4. After on-site testing, the height of the NCT half-shear bump is not more than 0.6T, and if it is greater than 0.6T, it is easy to fall off.

5. The above T indicates the sheet thickness.

Laser processing principle:

LASER is abbreviated by the prefix of Light Amplification by Stimulated Emission of Radition. Generally translated as laser. Laser cutting is the use of electron discharge as the energy source, through He, N2, CO2 and other mixed gases as the excitation medium, the use of the reflector group to generate a laser beam, cutting the material. Driven by a programmed servo motor, the cutting head moves according to a predetermined path to cut out various shapes of workpieces.

Laser machine common use: Blanking, cut shape, secondary cut, cut line, cut shaped hole

Laser machine processing accuracy: +/-0.1mm

LASER processing process and precautions:

1. When cutting the bottom hole of the metal part, it must be increased by 0.05mm. Because in the beginning and midpoint of the cut would have a tiny point.

For example: the bottom hole is φ5.4 should be cut into φ5.45.

Note: The bottom hole of metal parts is usually machined with NCT or die to ensure machining accuracy.

2. The width of the process hole is generally greater than 0.5mm, the smaller the burr, the more obvious.

3. In the secondary cutting from the plane to the convex hull face, the speed must be very slow, in fact similar to cutting thick materials.

4. LASER is hot processing, cutting mesh and thin material heat, it is easy to deform the workpiece.

5. If there is no special requirement on the acute angle of all workpieces, it must be rounded by R0.5mm when it is processed by LASER.

Bending processing principle

The upper and lower molds are respectively fixed on the upper and lower work platforms of the folding bed, and the relative movement of the worktable is driven by hydraulic transmission to combine the shapes of the upper and lower molds so as to realize the bending and bending forming of plate.

It is generally divided into up and down movements. The basic principle of the bending process sequence: bending from inside to outside. Bending from small to large.

First fold the special shape, then fold the general shape.

After the former process is formed, there is no interference with the subsequent process.

Bend processing accuracy:

One bending: +/-0.1mm

Two bending: +/-0.2mm

Tri-bending: +/-0.3mm

In the figure above, the dimension is the distance from the hole to the inner edge. If the distance is exceeded, the hole will be deformed. In this case, the deformation problem can be solved by other processing methods. If they are bent first and then cut with laser, or press cut line processing, or directly open the mold production, but this will increase the processing costs, as conditions allow, when designing to meet these minimum hole spacing.

1. Definition

2. Processing process introduction

3. Introduction to processing methods

4. Industry processing capacity introduction

Sheet metal processing is a comprehensive cold-working process for sheet metal (usually below 6mm), including shearing, blanking, bending, welding, riveting, molding and surface treatment. Its distinguishing feature is the uniform thickness of the same parts. According to different processing methods, they are generally divided into two categories:

1. Non-mold processing:

Through NCT (CNC punching), laser (laser cutting machine), CNC bending machine tools, rivets and other processing tools on the processing of sheet metal technology, generally used for rapid prototype production, higher cost.

2. Mold processing:

Through a fixed mold, the sheet metal is processed. Generally, there are blanking molds and forming molds, which are mainly used for mass production and have a low cost.

1. NCT (Numerical Control Machine) Processing

2. Laser (laser cutting) processing

3. Folding machine

4. pliers machine

5. Mold processing

6. Surface treatment

7. Sheet metal connection

Machining principle of NC machine tool:

CNC machine tools are flexible automatic machine tools that can adapt to frequent changes in products. The various operations and steps required for the machining process and the relative displacements between the tool and the workpiece are represented by digitized codes.The digital information is sent to a dedicated or general-purpose calculator via a control medium (such as a paper tape or a disk), and the calculator processes and calculates the input information. Various commands are issued to control the machine's servo system or other execution components so that the machine tool automatically processes the desired workpiece or product.

Common uses of CNC machine tools:

Unloading, punching mesh holes, punching bumps, trimming edges, bumps, pressing ribs, pressing lines, pumping holes.

(Pressing line is a kind of a variety of post-press processing methods, such as hot stamping, convex-concave, embossing, laminating, pressure lines, sticking, cutting, etc. are all postpress processing.

The minimum distance between two pressure lines is generally 3mm, but it also varies slightly depending on the processing object. ), CNC machine tool machining accuracy: +/- 0.1mm

NCT (Numerical Control Punch) processing process and precautions:

1. When the distance from the edge is less than the material thickness, Punching hole will cause the edge to turn up. Square hole is bigger and more obvious, usually considering LASER (laser cutting) two times cutting.

2. The distance between the hole and the edge of the NCT punching hole should not be too small. Its allowable value is shown in Table 1. The minimum hole diameter for the NCT punching is shown in Table 2:

3. Drawing hole:

The minimum distance from the edge of the NCT drawing hole is 3T. The minimum distance between the two drawing holes is 6T. The minimum safety distance from the punching edge (inside) is 3T+R. If it is too small, it must be handled by the pressure line.

4. After on-site testing, the height of the NCT half-shear bump is not more than 0.6T, and if it is greater than 0.6T, it is easy to fall off.

5. The above T indicates the sheet thickness.

Laser processing principle:

LASER is abbreviated by the prefix of Light Amplification by Stimulated Emission of Radition. Generally translated as laser. Laser cutting is the use of electron discharge as the energy source, through He, N2, CO2 and other mixed gases as the excitation medium, the use of the reflector group to generate a laser beam, cutting the material. Driven by a programmed servo motor, the cutting head moves according to a predetermined path to cut out various shapes of workpieces.

Laser machine common use: Blanking, cut shape, secondary cut, cut line, cut shaped hole

Laser machine processing accuracy: +/-0.1mm

LASER processing process and precautions:

1. When cutting the bottom hole of the metal part, it must be increased by 0.05mm. Because in the beginning and midpoint of the cut would have a tiny point.

For example: the bottom hole is φ5.4 should be cut into φ5.45.

Note: The bottom hole of metal parts is usually machined with NCT or die to ensure machining accuracy.

2. The width of the process hole is generally greater than 0.5mm, the smaller the burr, the more obvious.

3. In the secondary cutting from the plane to the convex hull face, the speed must be very slow, in fact similar to cutting thick materials.

4. LASER is hot processing, cutting mesh and thin material heat, it is easy to deform the workpiece.

5. If there is no special requirement on the acute angle of all workpieces, it must be rounded by R0.5mm when it is processed by LASER.

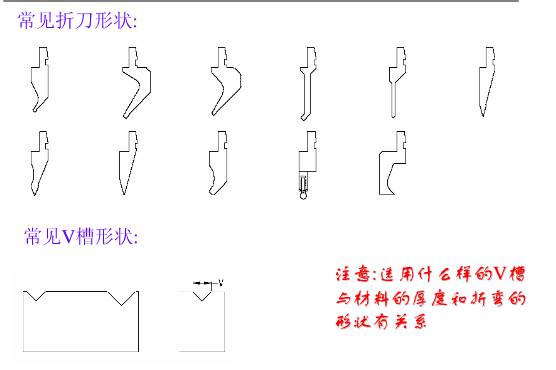

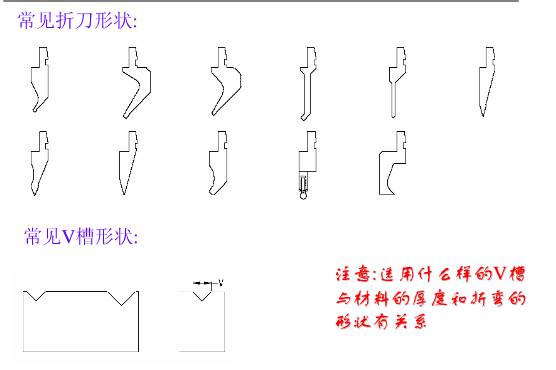

Bending processing principle

The upper and lower molds are respectively fixed on the upper and lower work platforms of the folding bed, and the relative movement of the worktable is driven by hydraulic transmission to combine the shapes of the upper and lower molds so as to realize the bending and bending forming of plate.

It is generally divided into up and down movements. The basic principle of the bending process sequence: bending from inside to outside. Bending from small to large.

First fold the special shape, then fold the general shape.

After the former process is formed, there is no interference with the subsequent process.

Bend processing accuracy:

One bending: +/-0.1mm

Two bending: +/-0.2mm

Tri-bending: +/-0.3mm

In the figure above, the dimension is the distance from the hole to the inner edge. If the distance is exceeded, the hole will be deformed. In this case, the deformation problem can be solved by other processing methods. If they are bent first and then cut with laser, or press cut line processing, or directly open the mold production, but this will increase the processing costs, as conditions allow, when designing to meet these minimum hole spacing.