Process Analysis of Complex Titanium Alloy Parts Milled and Finished by Machining Center

Analysis of Milling Process Characteristics of Titanium Alloy

Due to the slow heat dissipation in the milling area, it is not conducive to heat balance. During the cutting process, the heat dissipation and cooling effects are very poor, and it is easy to form a high temperature in the cutting zone. The large deformation and rebound of the machined parts result in the increase of the cutting tool torque, the rapid wear and tear of the cutting edge, and the decrease of the durability. Secondly, the low thermal conductivity of titanium alloy makes the cutting heat accumulated in a small area near the cutting tool not easy to emit, the friction force on the rake face increases, the chip removal is not easy, the cutting heat is not easy to emit, and the tool wear is accelerated. Titanium alloy has high chemical activity, and it is easy to react with tool materials at high temperature to form dissolution and diffusion, which causes sticking, burning and breaking.

What is titanium alloy?

Titanium alloys include alloying elements in industrial pure titanium to improve the strength of titanium.

Titanium alloys can be divided into three types: a titanium alloy, b titanium alloy and a + b titanium alloy. Titanium alloy a+b is composed of a and B phases. This kind of alloy has stable structure, good high temperature deformation performance, toughness and plasticity. It can be quenched and aged to strengthen the alloy.

The performance characteristics of titanium alloy are mainly manifested in:

1) High heat resistance. Titanium alloy has good thermal stability, and its strength is about 10 times higher than that of aluminum alloy at 300-500 °C.

2) Large chemical activity. Titanium can react strongly with oxygen, nitrogen, carbon monoxide, water vapor and other substances in the air to form TiC and TiN hardened layers on the surface.

2) Poor thermal conductivity. The thermal conductivity of titanium alloy is poor. The thermal conductivity of titanium alloy TC4 at 200 °C is 16.8 W/m•°C, and the thermal conductivity is 0.036 cal/cm•sec•°C.

Case Study on Milling of Titanium Alloy in Machining Center

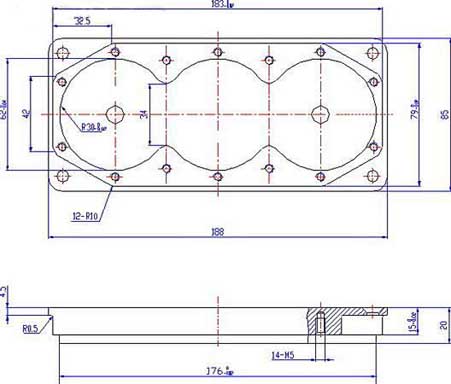

The structural form of the part is shown in Figure 1.

• The features of this part are as follows:

• The shape is complex and the precision is high.

• Multiple processes must be performed during processing.

• The tolerance range of parts must be strictly controlled.

• High prices and processing costs.

Tool material selection

Tool material selection should meet the following requirements:

• Sufficient hardness. The hardness of the tool must be much greater than the hardness of the titanium alloy.

• Sufficient strength and toughness. Since the tool is subjected to a large amount of torque and cutting force when cutting the titanium alloy, it must have sufficient strength and toughness.

• Sufficient wear resistance. Due to the good toughness of the titanium alloy and the sharpness of the cutting edge during machining, the tool material must have sufficient wear resistance to reduce work hardening. This is an important parameter for the selection of titanium alloy tools.

• Tool materials have a poor affinity with titanium alloys. Since the titanium alloy has high chemical activity, it is necessary to avoid the formation of alloys by melting and diffusion of the tool material and the titanium alloy, resulting in sticking and burning.

Tests on common tool materials and foreign tool materials in China show that the use of high-cobalt tools is ideal. The main role of cobalt can enhance the secondary hardening effect, improve the hardness of red hardness and heat treatment, and at the same time have high toughness, wear resistance and good heat dissipation.

Cutting parameter selection

Titanium alloy machining should choose a lower cutting speed, a suitable large feed, reasonable depth of cut and finishing, cooling should be sufficient.

• Cutting speed Vc Vc=30~50m/min

• Feed amount f Take a larger feed for roughing, and a moderate feed for finishing and semi-finishing.

• The cutting depth ap. ap = 1/3d is appropriate. The affinity of titanium alloy is good, the chip removal is difficult, and the cutting depth is too large, which will cause the tool to stick to the knife, burn the knife and break.

• The surface hardening layer of titanium alloy with moderate finishing allowance of alpha C is about 0.1-0.15 mm. If the cutting edge is cut on the hardened layer, the tool will wear easily. The hardened layer should be avoided, but the cutting allowance should not be too large.

Coolant

Titanium alloy processing does not use chlorine-containing coolant, avoiding the generation of toxic substances and causing hydrogen embrittlement, and also preventing high-temperature stress corrosion cracking of titanium alloy.

The synthetic water-soluble emulsion can be used, and the coolant can also be used.

The coolant should be sufficient during the cutting process, the coolant circulation speed should be fast, the cutting fluid flow rate and pressure should be large, and the machining center is equipped with a dedicated cooling nozzle, as long as the adjustment can achieve the desired effect.

Through the analysis of the characteristics of titanium alloy, the problems in the machining process of titanium alloy are solved; By compiling correct and scientific processing techniques, it is possible to reduce costs and increase production efficiency, and draw the following conclusions:

• Finishing titanium alloys with machining centers to meet the complex and high-precision requirements of parts, and multiple parts can be processed at the same time to improve production efficiency.

• High cobalt tool material is the ideal machining tool for titanium alloys.

• Selecting reasonable tool geometry, cutting parameters, and coolant can extend the life of the cutting tool and increase production efficiency.

• Arranging reasonable and scientific process procedures is the best way to improve efficiency and save costs.

Due to the slow heat dissipation in the milling area, it is not conducive to heat balance. During the cutting process, the heat dissipation and cooling effects are very poor, and it is easy to form a high temperature in the cutting zone. The large deformation and rebound of the machined parts result in the increase of the cutting tool torque, the rapid wear and tear of the cutting edge, and the decrease of the durability. Secondly, the low thermal conductivity of titanium alloy makes the cutting heat accumulated in a small area near the cutting tool not easy to emit, the friction force on the rake face increases, the chip removal is not easy, the cutting heat is not easy to emit, and the tool wear is accelerated. Titanium alloy has high chemical activity, and it is easy to react with tool materials at high temperature to form dissolution and diffusion, which causes sticking, burning and breaking.

What is titanium alloy?

Titanium alloys include alloying elements in industrial pure titanium to improve the strength of titanium.

Titanium alloys can be divided into three types: a titanium alloy, b titanium alloy and a + b titanium alloy. Titanium alloy a+b is composed of a and B phases. This kind of alloy has stable structure, good high temperature deformation performance, toughness and plasticity. It can be quenched and aged to strengthen the alloy.

The performance characteristics of titanium alloy are mainly manifested in:

1) High heat resistance. Titanium alloy has good thermal stability, and its strength is about 10 times higher than that of aluminum alloy at 300-500 °C.

2) Large chemical activity. Titanium can react strongly with oxygen, nitrogen, carbon monoxide, water vapor and other substances in the air to form TiC and TiN hardened layers on the surface.

2) Poor thermal conductivity. The thermal conductivity of titanium alloy is poor. The thermal conductivity of titanium alloy TC4 at 200 °C is 16.8 W/m•°C, and the thermal conductivity is 0.036 cal/cm•sec•°C.

Case Study on Milling of Titanium Alloy in Machining Center

The structural form of the part is shown in Figure 1.

Figure 1. Shape dimensions of parts

• The features of this part are as follows:

• The shape is complex and the precision is high.

• Multiple processes must be performed during processing.

• The tolerance range of parts must be strictly controlled.

• High prices and processing costs.

Characteristics of Titanium Alloy Processing by Machining Center

Tool material selection

Tool material selection should meet the following requirements:

• Sufficient hardness. The hardness of the tool must be much greater than the hardness of the titanium alloy.

• Sufficient strength and toughness. Since the tool is subjected to a large amount of torque and cutting force when cutting the titanium alloy, it must have sufficient strength and toughness.

• Sufficient wear resistance. Due to the good toughness of the titanium alloy and the sharpness of the cutting edge during machining, the tool material must have sufficient wear resistance to reduce work hardening. This is an important parameter for the selection of titanium alloy tools.

• Tool materials have a poor affinity with titanium alloys. Since the titanium alloy has high chemical activity, it is necessary to avoid the formation of alloys by melting and diffusion of the tool material and the titanium alloy, resulting in sticking and burning.

Tests on common tool materials and foreign tool materials in China show that the use of high-cobalt tools is ideal. The main role of cobalt can enhance the secondary hardening effect, improve the hardness of red hardness and heat treatment, and at the same time have high toughness, wear resistance and good heat dissipation.

Cutting parameter selection

Titanium alloy machining should choose a lower cutting speed, a suitable large feed, reasonable depth of cut and finishing, cooling should be sufficient.

• Cutting speed Vc Vc=30~50m/min

• Feed amount f Take a larger feed for roughing, and a moderate feed for finishing and semi-finishing.

• The cutting depth ap. ap = 1/3d is appropriate. The affinity of titanium alloy is good, the chip removal is difficult, and the cutting depth is too large, which will cause the tool to stick to the knife, burn the knife and break.

• The surface hardening layer of titanium alloy with moderate finishing allowance of alpha C is about 0.1-0.15 mm. If the cutting edge is cut on the hardened layer, the tool will wear easily. The hardened layer should be avoided, but the cutting allowance should not be too large.

Coolant

Titanium alloy processing does not use chlorine-containing coolant, avoiding the generation of toxic substances and causing hydrogen embrittlement, and also preventing high-temperature stress corrosion cracking of titanium alloy.

The synthetic water-soluble emulsion can be used, and the coolant can also be used.

The coolant should be sufficient during the cutting process, the coolant circulation speed should be fast, the cutting fluid flow rate and pressure should be large, and the machining center is equipped with a dedicated cooling nozzle, as long as the adjustment can achieve the desired effect.

Through the analysis of the characteristics of titanium alloy, the problems in the machining process of titanium alloy are solved; By compiling correct and scientific processing techniques, it is possible to reduce costs and increase production efficiency, and draw the following conclusions:

• Finishing titanium alloys with machining centers to meet the complex and high-precision requirements of parts, and multiple parts can be processed at the same time to improve production efficiency.

• High cobalt tool material is the ideal machining tool for titanium alloys.

• Selecting reasonable tool geometry, cutting parameters, and coolant can extend the life of the cutting tool and increase production efficiency.

• Arranging reasonable and scientific process procedures is the best way to improve efficiency and save costs.