Metal Products Rust Causes And Solutions

According to statistics, the loss caused by metal corrosion is very alarming each year. The amount of metal lost in the world due to corrosion each year accounts for about 10% of the annual production. In foreign countries, the annual loss of metal rust accounts for about 2-4% of the national economy's total output value; China's metal rust loss is also close to 10 billion RMB per year.

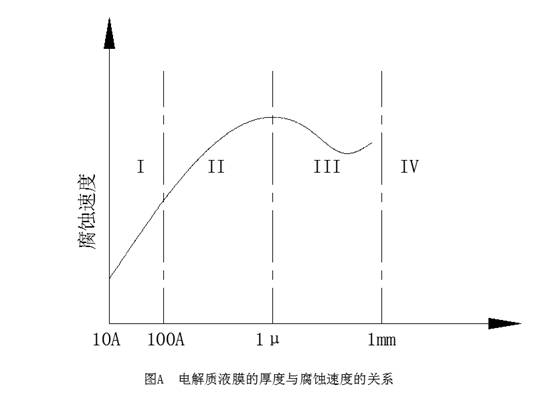

Figure A Relationship between electrolyte thickness and corrosion rate

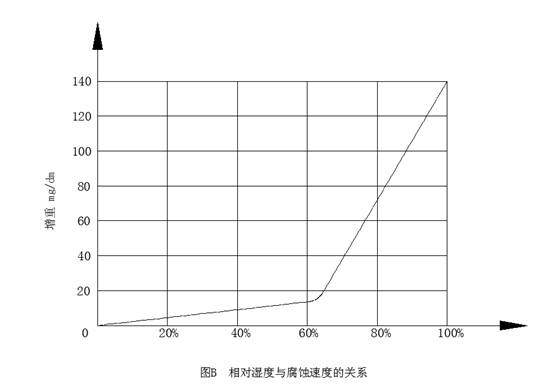

Figure B. Relationship between relative humidity and corrosion degree

Thus, in the management of the temperature and humidity of the inventory metal equipment, as long as the humidity is managed below the critical humidity of the metal (65-70%), the corrosion of the metal can be basically prevented.

If the humidity is not properly controlled in the inventory management, the relative humidity rises above the critical humidity of metal corrosion, and metal equipment is stored in such an environment and it is prone to rust. After rusting metal equipment, the resulting rust is more likely to absorb moisture and accelerate rust.

Therefore, the relative humidity of the warehouse where the metal equipment is stored must be controlled within the critical humidity of the metal, so as to delay the corrosion of the metal. Atmospheric temperature also has a great influence on the corrosion of metals, especially when there is a large change in temperature, hot and humid air encounters cold metals, causing condensation on the metal surface, which will greatly accelerate metal corrosion. Therefore, in high temperature and high humidity areas, metals are particularly susceptible to rust. To sum up, doing a good job of temperature and humidity management is of great significance for preventing and delaying metal corrosion.

Storage of metal equipment

General principles for selecting suitable custody

a) Choosing a suitable storage place

The place where the metal equipment is stored shall be clean and dry, besides the inside of the warehouse, away from factories and workshops that produce harmful gases and dust, and not be mixed with acids, alkalis, salts, gases, dust, etc. To sort, batch storage; When different types of metal equipment are stored in the same place, there must be a clear separation distance to prevent contact corrosion. General steel, pipe, etc. can be stored in sheds or twisted mats; All ferroalloys, small steel sheets, steel strips, precision tubes, metal products and non-ferrous metal materials should be stored in warehouses. Conditional metal warehouses should be reserved for special warehouses.

b) Keep the warehouse dry

To ensure that the relative humidity of the warehouse is below the critical humidity, the relative humidity should generally be controlled at about 70%. Manage the warehouse's temperature and humidity, keep abreast of weather changes, avoid typhoons, heavy rain, and use ventilation methods to cool down and reduce tides. Industrial dehumidifiers and desiccants can also be used to reduce moisture.

Keeping the warehouse dry is an important condition for safeguarding storage hardware equipment to prevent or reduce corrosion.

c) Proper palletizing, Mat mat and sealing

Proper palletizing and matting are also one of the links for moisture protection and loss prevention of hardware equipment.

The pallets are required to be reasonable, firm, quantitative, tidy and space-saving.

The seal isolates the metal material from the outside air to reduce the effect of moisture on the rust.

Metal materials that are kept sealed must not have been exposed to moisture before sealing, and the quality is good.

d) Oil injection rust prevention

In the humid and hot regions of the South, open storage of metal equipment, using only the lid can not achieve the desired anti-rust purposes, you can also spray oil and rust. However, this method cannot be adopted for construction steel bars and cold-rolled and cold drawn steels that are not suitable for injection.

e) Protective layer and packaging of protective equipment

In order to prevent rusting of metal products, rust-prevention treatment is generally performed at the factory, such as chemical treatment to form a protective film, coating rust inhibitor or rust-proof packaging, etc. In the operations of handling, loading and unloading, and storage, it is necessary to prevent damage to the rust-proof outer layer and the package so that it will not be damaged, scratched or deformed under pressure. Damaged packaging should be repaired or replaced. The damp product should be dried, and the rust-proof oil dirty or dried should be removed and re-oiled.

f) Keep the warehouse and equipment clean

Metal equipment in warehouses and depositories should always be kept clean. In particular, after seaborne equipment, such as contaminated with sea water, dirt is generally not put into stock, but should be promptly cleaned up, quickly put into production use. Metal equipment stained with sweat will rust and corrosion, so as far as possible to avoid hand sweat and contamination of hardware products. Storage equipment should not be in contact with dirt and groceries, and dust should be deposited.

g) Strengthen the inspection system and find problems in time

During the custody of hardware equipment, it is necessary to implement an inspection system and carry out routine, regular and irregular inspections so that problems can be detected in a timely manner and handled in a timely manner. All kinds of anti-rust measures for hardware equipment can only play a role in corrosion inhibition, so the storage should have a certain period of time, and the principles of first-in, first-out, and rotating delivery should be implemented.

The above methods are simple to say, and they are really simple to do. However, they are more tedious and careful, and they require more patience. Too many factors affect metal rust, making it difficult to prevent them. Modern people prefer to have a once and forever method that can completely eliminate metal rust. Dehumidifiers, especially industrial dehumidifiers suitable for workshops and warehouses, can solve the problem of excessive humidity. Strict requirements on the temperature and humidity steel special steel, of course, using a constant temperature and humidity machine is better, from the two aspects of temperature and humidity, to prevent metal rust corrosion!

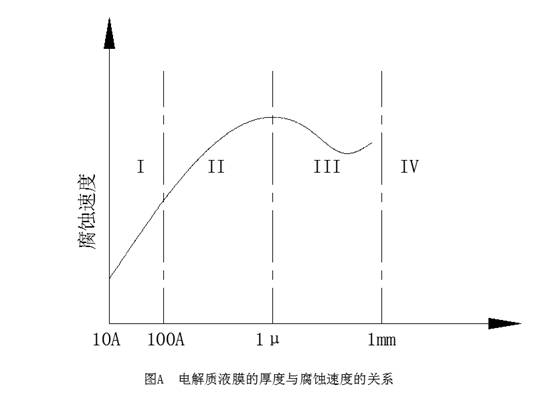

Figure A Relationship between electrolyte thickness and corrosion rate

The thickness of the liquid film in regions III and IV reaches the level visible to the naked eye. However, with the thickening of the liquid film, the diffusion of oxygen slows and the corrosion rate decreases. In materials warehouses, corrosion of metal equipment is generally carried out in areas I and II. This shows that the degree of moisture is quite serious for metal corrosion.

In the warehouse temperature and humidity management, in order to quantitatively describe the corrosion rate, it is often measured by the relative humidity of the air.

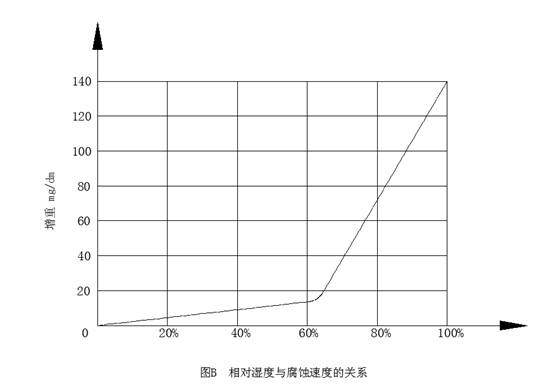

The relative humidity of the air. It has a great influence on the corrosion rate of metal in the atmosphere. Experience has shown that under certain temperature conditions, if the relative humidity of air is kept below 70%, the corrosion to metal is very slight. If the relative humidity increases above the critical humidity of metal corrosion, the corrosion rate of the metal begins to increase rapidly. Figure B shows the relationship between the corrosion rate of iron and the relative humidity of air. That is, the relationship between corrosion rate and relative humidity of iron in air (containing 0.01% SO2) at a temperature of 25°C after 55 days. The figure shows that below the critical humidity, the metal surface is difficult to form a primary battery due to the lack of a water film, and is subject to chemical corrosion, and the corrosion rate is very slow. When the critical humidity is high, due to the formation of a water film, chemical corrosion is converted into electrochemical corrosion, which accelerates the corrosion rate.

In the warehouse temperature and humidity management, in order to quantitatively describe the corrosion rate, it is often measured by the relative humidity of the air.

The relative humidity of the air. It has a great influence on the corrosion rate of metal in the atmosphere. Experience has shown that under certain temperature conditions, if the relative humidity of air is kept below 70%, the corrosion to metal is very slight. If the relative humidity increases above the critical humidity of metal corrosion, the corrosion rate of the metal begins to increase rapidly. Figure B shows the relationship between the corrosion rate of iron and the relative humidity of air. That is, the relationship between corrosion rate and relative humidity of iron in air (containing 0.01% SO2) at a temperature of 25°C after 55 days. The figure shows that below the critical humidity, the metal surface is difficult to form a primary battery due to the lack of a water film, and is subject to chemical corrosion, and the corrosion rate is very slow. When the critical humidity is high, due to the formation of a water film, chemical corrosion is converted into electrochemical corrosion, which accelerates the corrosion rate.

Figure B. Relationship between relative humidity and corrosion degree

Thus, in the management of the temperature and humidity of the inventory metal equipment, as long as the humidity is managed below the critical humidity of the metal (65-70%), the corrosion of the metal can be basically prevented.

If the humidity is not properly controlled in the inventory management, the relative humidity rises above the critical humidity of metal corrosion, and metal equipment is stored in such an environment and it is prone to rust. After rusting metal equipment, the resulting rust is more likely to absorb moisture and accelerate rust.

Therefore, the relative humidity of the warehouse where the metal equipment is stored must be controlled within the critical humidity of the metal, so as to delay the corrosion of the metal. Atmospheric temperature also has a great influence on the corrosion of metals, especially when there is a large change in temperature, hot and humid air encounters cold metals, causing condensation on the metal surface, which will greatly accelerate metal corrosion. Therefore, in high temperature and high humidity areas, metals are particularly susceptible to rust. To sum up, doing a good job of temperature and humidity management is of great significance for preventing and delaying metal corrosion.

Storage of metal equipment

General principles for selecting suitable custody

a) Choosing a suitable storage place

The place where the metal equipment is stored shall be clean and dry, besides the inside of the warehouse, away from factories and workshops that produce harmful gases and dust, and not be mixed with acids, alkalis, salts, gases, dust, etc. To sort, batch storage; When different types of metal equipment are stored in the same place, there must be a clear separation distance to prevent contact corrosion. General steel, pipe, etc. can be stored in sheds or twisted mats; All ferroalloys, small steel sheets, steel strips, precision tubes, metal products and non-ferrous metal materials should be stored in warehouses. Conditional metal warehouses should be reserved for special warehouses.

b) Keep the warehouse dry

To ensure that the relative humidity of the warehouse is below the critical humidity, the relative humidity should generally be controlled at about 70%. Manage the warehouse's temperature and humidity, keep abreast of weather changes, avoid typhoons, heavy rain, and use ventilation methods to cool down and reduce tides. Industrial dehumidifiers and desiccants can also be used to reduce moisture.

Keeping the warehouse dry is an important condition for safeguarding storage hardware equipment to prevent or reduce corrosion.

c) Proper palletizing, Mat mat and sealing

Proper palletizing and matting are also one of the links for moisture protection and loss prevention of hardware equipment.

The pallets are required to be reasonable, firm, quantitative, tidy and space-saving.

The seal isolates the metal material from the outside air to reduce the effect of moisture on the rust.

Metal materials that are kept sealed must not have been exposed to moisture before sealing, and the quality is good.

d) Oil injection rust prevention

In the humid and hot regions of the South, open storage of metal equipment, using only the lid can not achieve the desired anti-rust purposes, you can also spray oil and rust. However, this method cannot be adopted for construction steel bars and cold-rolled and cold drawn steels that are not suitable for injection.

e) Protective layer and packaging of protective equipment

In order to prevent rusting of metal products, rust-prevention treatment is generally performed at the factory, such as chemical treatment to form a protective film, coating rust inhibitor or rust-proof packaging, etc. In the operations of handling, loading and unloading, and storage, it is necessary to prevent damage to the rust-proof outer layer and the package so that it will not be damaged, scratched or deformed under pressure. Damaged packaging should be repaired or replaced. The damp product should be dried, and the rust-proof oil dirty or dried should be removed and re-oiled.

f) Keep the warehouse and equipment clean

Metal equipment in warehouses and depositories should always be kept clean. In particular, after seaborne equipment, such as contaminated with sea water, dirt is generally not put into stock, but should be promptly cleaned up, quickly put into production use. Metal equipment stained with sweat will rust and corrosion, so as far as possible to avoid hand sweat and contamination of hardware products. Storage equipment should not be in contact with dirt and groceries, and dust should be deposited.

g) Strengthen the inspection system and find problems in time

During the custody of hardware equipment, it is necessary to implement an inspection system and carry out routine, regular and irregular inspections so that problems can be detected in a timely manner and handled in a timely manner. All kinds of anti-rust measures for hardware equipment can only play a role in corrosion inhibition, so the storage should have a certain period of time, and the principles of first-in, first-out, and rotating delivery should be implemented.

The above methods are simple to say, and they are really simple to do. However, they are more tedious and careful, and they require more patience. Too many factors affect metal rust, making it difficult to prevent them. Modern people prefer to have a once and forever method that can completely eliminate metal rust. Dehumidifiers, especially industrial dehumidifiers suitable for workshops and warehouses, can solve the problem of excessive humidity. Strict requirements on the temperature and humidity steel special steel, of course, using a constant temperature and humidity machine is better, from the two aspects of temperature and humidity, to prevent metal rust corrosion!