Lathe Turning Parts Set Groove

Set the groove on the part.

First, in order to facilitate the subsequent processing, such as lathe turning thread undercut, grinding over-traveling groove, etc.;

The second is to ensure the accuracy of the axial positioning of the parts during assembly, such as the shoulder groove;

The third is a T-shaped groove and a dovetail groove for freely moving or fastening;

The fourth is to set different types of lubrication grooves on the mating surfaces that move with each other, as well as sealing grooves and dust grooves for sealing or dustproofing. The structure of the groove has a rectangular groove, a forming groove, a slanting tank and an end groove. According to the groove portion, it can be divided into an outer groove and an inner groove. Cutting of rectangular grooves: When turning rectangular groove, the geometric parameters and installation method of the slot cutter are similar to those of the cutter. They also have two symmetrical tool tips, sub-deflection angle and sub-rear angle. The main cutting edge is parallel to the axis of the workpiece.

The basic method of cutting a rectangular slot is:

1) When cutting a narrow rectangular groove, the width of the main cutting edge is equal to the width of the groove, the length of the cutter head is slightly larger than the groove depth, and the turning tool is straight in and out.

2) Turning a wide rectangular groove, you can use a narrow grooving knife to divide the boring tool several times, and leave a margin on the bottom and sides of the groove.

Cutting of the forming groove:

The forming groove includes a circular arc groove, a trapezoidal groove, and the like.

1) The narrow arc groove or trapezoidal groove is used to grind the rim blade into the same shape and size as the forming groove, and the vehicle is fed in one horizontal direction.

2) The wider and deeper forming groove, especially the forming groove of the inner hole, is restricted by the rigidity of the turning tool.

There are two ways to do this:

1> Cut in two steps. Generally, the grooving cutter is used to drive out the straight groove, and then it is formed by turning with a forming knife.

2> Left or right sickle feed or oblique feed.

When the lathe is extremely wide and deep, the small skateboard can be shaken while the middle slide is being moved laterally, so that the turning tool can be moved to the left or right to form a left and right boring tool for single-sided cutting;

Or while the middle slide is fed laterally, the small slide is shaken to make the single-sided oblique feed of the turning tool in one direction. After the rough car, the balance is left, and then the car is used to the size.

Cutting of the oblique groove:

1) Use a straight groove in the end face to cut the knife and feed it longitudinally. Turn the straight end groove.

2) Use the elbow right grooving knife instead of the straight hole in the car. Turn the outer groove.

3) Turn the slot cutter to the left side groove with the elbow.

(3) The steps and methods of the dovetail slot of the car swallowtail slot are basically the same as the method of cutting the T-slot. It is also carried out in three steps using three turning knives. That is, after turning the straight groove of the end face, the left and right bevel forming knives are respectively used to form the dovetail groove.

When turning the T-slot and the dovetail groove, the cutting edge on the outside of the turning should also be sharpened according to the principle of the inner hole turning tool.

The lathe is also limited by the width of the straight groove on the end face. The left and right elbow grooving knives and the left and right slant forming knives are thinner and the strength of the cutter head is poor. Therefore, the feed rate should be appropriately reduced, and the chip removal condition should be observed at any time and cleared in time.

When using a high-speed steel turning tool, the lathe should also reduce the cutting speed and fill the cutting fluid.

First, in order to facilitate the subsequent processing, such as lathe turning thread undercut, grinding over-traveling groove, etc.;

The second is to ensure the accuracy of the axial positioning of the parts during assembly, such as the shoulder groove;

The third is a T-shaped groove and a dovetail groove for freely moving or fastening;

The fourth is to set different types of lubrication grooves on the mating surfaces that move with each other, as well as sealing grooves and dust grooves for sealing or dustproofing. The structure of the groove has a rectangular groove, a forming groove, a slanting tank and an end groove. According to the groove portion, it can be divided into an outer groove and an inner groove. Cutting of rectangular grooves: When turning rectangular groove, the geometric parameters and installation method of the slot cutter are similar to those of the cutter. They also have two symmetrical tool tips, sub-deflection angle and sub-rear angle. The main cutting edge is parallel to the axis of the workpiece.

The basic method of cutting a rectangular slot is:

1) When cutting a narrow rectangular groove, the width of the main cutting edge is equal to the width of the groove, the length of the cutter head is slightly larger than the groove depth, and the turning tool is straight in and out.

2) Turning a wide rectangular groove, you can use a narrow grooving knife to divide the boring tool several times, and leave a margin on the bottom and sides of the groove.

Cutting of the forming groove:

The forming groove includes a circular arc groove, a trapezoidal groove, and the like.

1) The narrow arc groove or trapezoidal groove is used to grind the rim blade into the same shape and size as the forming groove, and the vehicle is fed in one horizontal direction.

2) The wider and deeper forming groove, especially the forming groove of the inner hole, is restricted by the rigidity of the turning tool.

There are two ways to do this:

1> Cut in two steps. Generally, the grooving cutter is used to drive out the straight groove, and then it is formed by turning with a forming knife.

2> Left or right sickle feed or oblique feed.

When the lathe is extremely wide and deep, the small skateboard can be shaken while the middle slide is being moved laterally, so that the turning tool can be moved to the left or right to form a left and right boring tool for single-sided cutting;

Or while the middle slide is fed laterally, the small slide is shaken to make the single-sided oblique feed of the turning tool in one direction. After the rough car, the balance is left, and then the car is used to the size.

Cutting of the oblique groove:

The oblique groove is an overrun groove for simultaneously grinding the cylindrical surface and the end surface, and forms an empty knife in both the cylindrical surface and the end surface.

The oblique grooves are linear and circular, with a general inclination of 45. The lathe grooving cutter has the characteristics of the inner hole turning tool. It should be ground into the corresponding arc back angle according to the size of the groove arc.

When cutting, turn the small slide to 450 and cut it with a small slide.

Cutting of the face groove:

The grooving knife for cutting the end face groove has the comprehensive characteristics of the outer turning tool and the inner hole turning tool. Two cutting edges inside and outside, one is equivalent to an outer turning tool, and the other is equivalent to an inner hole turning tool. Lathes should therefore be based on their respective cutting characteristics. Sharpen the grooving knife.

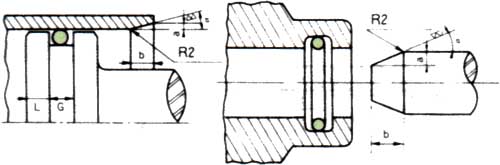

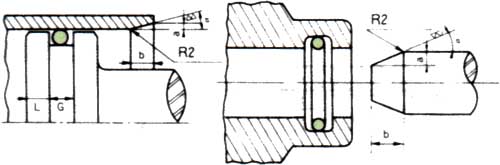

(1) The geometry of the straight groove grooving cutter on the end face of the straight end face of the vehicle. The outer edge of the lathe cutter. It is equivalent to turning the inner hole, so the rear side of the pair should be ground according to the size of the arc of the end face, and the corresponding arc-shaped sub-back angle R is ground to prevent the rear side from colliding with the outer groove surface.

(2) The T-slot of the T-slot truck, which is applied in three steps using three turning tools:

The oblique grooves are linear and circular, with a general inclination of 45. The lathe grooving cutter has the characteristics of the inner hole turning tool. It should be ground into the corresponding arc back angle according to the size of the groove arc.

When cutting, turn the small slide to 450 and cut it with a small slide.

Cutting of the face groove:

The grooving knife for cutting the end face groove has the comprehensive characteristics of the outer turning tool and the inner hole turning tool. Two cutting edges inside and outside, one is equivalent to an outer turning tool, and the other is equivalent to an inner hole turning tool. Lathes should therefore be based on their respective cutting characteristics. Sharpen the grooving knife.

(1) The geometry of the straight groove grooving cutter on the end face of the straight end face of the vehicle. The outer edge of the lathe cutter. It is equivalent to turning the inner hole, so the rear side of the pair should be ground according to the size of the arc of the end face, and the corresponding arc-shaped sub-back angle R is ground to prevent the rear side from colliding with the outer groove surface.

(2) The T-slot of the T-slot truck, which is applied in three steps using three turning tools:

2) Use the elbow right grooving knife instead of the straight hole in the car. Turn the outer groove.

3) Turn the slot cutter to the left side groove with the elbow.

(3) The steps and methods of the dovetail slot of the car swallowtail slot are basically the same as the method of cutting the T-slot. It is also carried out in three steps using three turning knives. That is, after turning the straight groove of the end face, the left and right bevel forming knives are respectively used to form the dovetail groove.

When turning the T-slot and the dovetail groove, the cutting edge on the outside of the turning should also be sharpened according to the principle of the inner hole turning tool.

The lathe is also limited by the width of the straight groove on the end face. The left and right elbow grooving knives and the left and right slant forming knives are thinner and the strength of the cutter head is poor. Therefore, the feed rate should be appropriately reduced, and the chip removal condition should be observed at any time and cleared in time.

When using a high-speed steel turning tool, the lathe should also reduce the cutting speed and fill the cutting fluid.