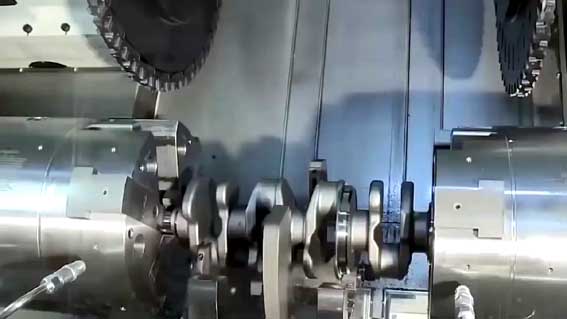

How to machining the camshaft?

The camshaft is generally machined: It is divided into cam surface roughing, cam surface finishing, etc. The machining stage is divided during the machining process, and the machining process is analyzed. If there is a quality problem in the processing of the camshaft, it should be resolved in time. The above is explained below.

Processing stage:

roughing: Each support journal, timing gear journal and threaded journal outer circle, car cam, eccentric wheel, and the like.

Semi-finishing: Rough grinding cam, eccentric wheel, etc.

finishing: Fine grinding timing pin journal and thrust surface, four bearing journal outer circle, fine grinding cam, eccentric wheel.

Finishing: Polished support journals, cams and eccentrics.

2. Cam surface roughing

Positioning: Positioning with a bearing journal end face as an axial direction; Using a timing gear and a support shaft outer circle as a positioning reference; A roller-type auxiliary support is used in the machining.

3. Cam surface finishing

Double cam grinding machine: The machine has two sets of masters, which are automatically replaced by the master. The accuracy of the cam profile is improved by controlling the diameter of the grinding wheel.

Double cycle cam grinder: The entire cam on the camshaft can be continuously coarsely ground after one installation. First, coarsely grind all the cams at a high feed rate of 60 m/s, and finish grinding all the cams at a grinding speed of 30 m/s, and correct them after finishing.

4. Analysis of camshaft machining process

(1) The cubic boron nitride grinding wheel is used to improve the life, reduce the wear of the grinding wheel and improve the precision.

(2) CNC cam grinder: Apply computer to NC programming to get rid of the influence of the accuracy of the cam on the cam precision.(3) use of electric - hydraulic control head frame pulse motor, a wheel frame synchronization.

(4) High-speed grinding using multiple grinding wheels and high-strength grinding wheels.

(5) The grinding wheel shaft swinging device is used to reduce the surface roughness of the cam surface.

(6) Pre-selection devices such as pre-selected coarse and fine grinding allowances are used.

(7) Adopt active measuring device.

(8) Adopt automatic compensation, automatic trimming and other devices.

5. Quality problems and solutions that are prone to occur in camshaft machining

(1) After finishing the axle, the grinding wheel is not round

Possible problems: Processing with a single-board machine, the program is chaotic, the processing size is unstable, and the beating is super poor.

solution: Replace the bearing journal turning device, the change control system, SBC regular inspection.

(2) Cam lift tolerance

Possible problems: The machine tool is worn by the die and the accuracy of the die is reduced.

solution: Regular inspection, trimming, and timely replacement of the master. When grinding the cam surface, a method of changing the direction of rotation of the workpiece is used to improve the shape accuracy of the cam curve.

(3) Cam base bounce is out of tolerance

Possible problems: The machine tool is worn by the die and the accuracy of the die is reduced.

solution: Regular inspection, trimming, and even replacement of the master and coupling guide shaft.

Processing stage:

roughing: Each support journal, timing gear journal and threaded journal outer circle, car cam, eccentric wheel, and the like.

Semi-finishing: Rough grinding cam, eccentric wheel, etc.

finishing: Fine grinding timing pin journal and thrust surface, four bearing journal outer circle, fine grinding cam, eccentric wheel.

Finishing: Polished support journals, cams and eccentrics.

2. Cam surface roughing

Positioning: Positioning with a bearing journal end face as an axial direction; Using a timing gear and a support shaft outer circle as a positioning reference; A roller-type auxiliary support is used in the machining.

3. Cam surface finishing

Double cam grinding machine: The machine has two sets of masters, which are automatically replaced by the master. The accuracy of the cam profile is improved by controlling the diameter of the grinding wheel.

Double cycle cam grinder: The entire cam on the camshaft can be continuously coarsely ground after one installation. First, coarsely grind all the cams at a high feed rate of 60 m/s, and finish grinding all the cams at a grinding speed of 30 m/s, and correct them after finishing.

4. Analysis of camshaft machining process

(1) The cubic boron nitride grinding wheel is used to improve the life, reduce the wear of the grinding wheel and improve the precision.

(2) CNC cam grinder: Apply computer to NC programming to get rid of the influence of the accuracy of the cam on the cam precision.(3) use of electric - hydraulic control head frame pulse motor, a wheel frame synchronization.

(4) High-speed grinding using multiple grinding wheels and high-strength grinding wheels.

(5) The grinding wheel shaft swinging device is used to reduce the surface roughness of the cam surface.

(6) Pre-selection devices such as pre-selected coarse and fine grinding allowances are used.

(7) Adopt active measuring device.

(8) Adopt automatic compensation, automatic trimming and other devices.

5. Quality problems and solutions that are prone to occur in camshaft machining

(1) After finishing the axle, the grinding wheel is not round

Possible problems: Processing with a single-board machine, the program is chaotic, the processing size is unstable, and the beating is super poor.

solution: Replace the bearing journal turning device, the change control system, SBC regular inspection.

(2) Cam lift tolerance

Possible problems: The machine tool is worn by the die and the accuracy of the die is reduced.

solution: Regular inspection, trimming, and timely replacement of the master. When grinding the cam surface, a method of changing the direction of rotation of the workpiece is used to improve the shape accuracy of the cam curve.

(3) Cam base bounce is out of tolerance

Possible problems: The machine tool is worn by the die and the accuracy of the die is reduced.

solution: Regular inspection, trimming, and even replacement of the master and coupling guide shaft.