High-precision machining and grinding of large-diameter thin-walled sleeves

In the towed concrete pump truck, there is a typical large diameter thin walled part - the intermediate sleeve. The inner hole has a diameter of 202 mm, an outer diameter of 212 mm, and a wall thickness of only 5 mm. Moreover, the positional accuracy between the dimensions of the part is required to be high, the outer surface roughness Ra is required to be 0.4 μm, and the outer circularness error is required to be less than 0.010 mm. Due to the thin wall thickness of the part, when the outer circle is ground, if the measures are not taken, the workpiece will often be deformed greatly due to the clamping force, the grinding force, the grinding heat, the internal stress and the like. The quality of the part cannot be guaranteed to reduce the deformation of the part.

The Japanese NVGII series of twin-spindle CNC vertical composite grinding machines provided by KangDIng provides a good solution.

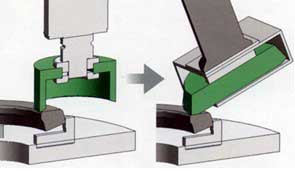

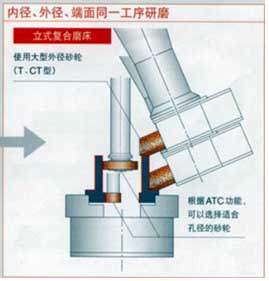

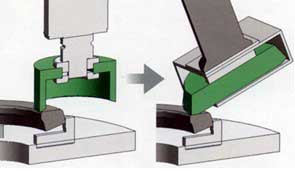

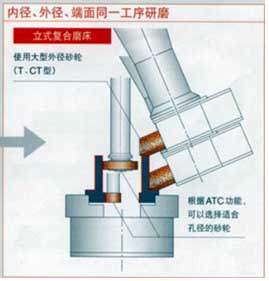

1. The inner diameter, outer diameter and end surface can be completed in one clamping.

2, high precision.

Roundness Φ120mm inner diameter: 0.65μm;

Φ160mm outer diameter: 0.45μm;

Φ170mm outer diameter: 0.55μm.

Cylindricity Φ120mm inner diameter: 1.5μm;

Φ170mm outer diameter: 1.5μm.

Coaxiality Φ120mm, Φ170mm: 0.85μm.

Surface roughness 120mm inner diameter: 1.16μm Rz;

Φ170mm outer diameter: 1.80μm Rz.

3, high efficiency

Equipped with a turret type grinding wheel, it can be driven in 3 positions by large coupling and servo motor drive. By using a high-rigidity external grinding spindle, stable and superior grinding performance can be achieved, and the bevel grinding wheel greatly improves the efficiency of end face machining.

The Japanese NVGII series of twin-spindle CNC vertical composite grinding machines provided by KangDIng provides a good solution.

1. The inner diameter, outer diameter and end surface can be completed in one clamping.

2, high precision.

Roundness Φ120mm inner diameter: 0.65μm;

Φ160mm outer diameter: 0.45μm;

Φ170mm outer diameter: 0.55μm.

Cylindricity Φ120mm inner diameter: 1.5μm;

Φ170mm outer diameter: 1.5μm.

Coaxiality Φ120mm, Φ170mm: 0.85μm.

Surface roughness 120mm inner diameter: 1.16μm Rz;

Φ170mm outer diameter: 1.80μm Rz.

3, high efficiency

Equipped with a turret type grinding wheel, it can be driven in 3 positions by large coupling and servo motor drive. By using a high-rigidity external grinding spindle, stable and superior grinding performance can be achieved, and the bevel grinding wheel greatly improves the efficiency of end face machining.