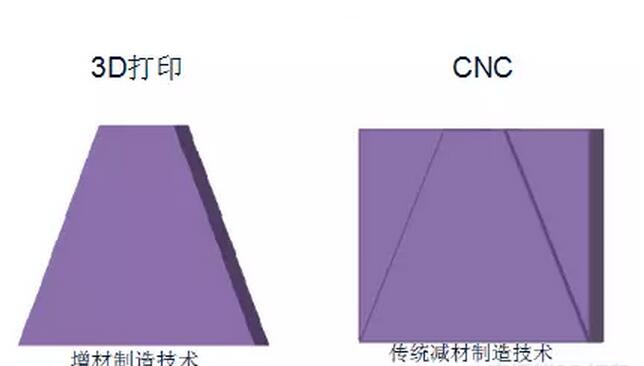

Comparison of 3D Printing and CNC Machining Prototype

In recent years, prototypes of 3D printing products have become more and more popular. So what is the difference between 3D printing and traditional processing giant CNC machining?

Next, Kangding compares the specific differences between two different processing methods for everyone.

3D printing principle

The principle of 3D printing is through the use of special materials, layer by layer, "stacked," commonly known as "additive manufacturing."

In simple terms, the principle of CNC machining is to cut and process the whole piece of material into the specified shape of the product, which is also called “reduce material manufacturing”.

Different materials

General hand material CNC can be processed:

1, plastic hand board material: ABS, PC, POM, PP, acrylic (PMMA), nylon, Bakelite, Teflon, PBT, PPS, PEET, polyurethane foam, etc.;

2, hardware Shouban materials are: aluminum, aluminum-magnesium alloy, aluminum-zinc alloy, copper, steel, iron, titanium alloy, etc;

Current 3D printing (SLA) processing materials: ABS, PC type materials, PLA, nylon, photosensitive resin, rubber materials

The 3D printed metal powder materials mainly include titanium alloys, cobalt-chromium alloys, stainless steels, and aluminum alloy materials. In addition, there are also precious metal powder materials for printing jewelry such as gold and silver.

Other 3D printing materials: Colored gypsum materials, artificial bone powder, cell biological raw materials, and sugar and other materials.

Material utilization is different

3D printing, due to its unique additive manufacturing, material utilization is extremely high.

CNC machining, due to the need to reduce the entire material, and then get the final product, so the utilization of CNC machining materials is not high.

Processing comparison

Programming:

3D printing: comes with driver software that automatically calculates printing time and supplies.

CNC Machining: Professional programmers and operating personnel are required.

Processing number:

3D Printing: As long as the tray is sufficient, multiple parts can be printed at one time without manual attendance.

CNC: Only one part can be machined at a time.

Processing time:

3D printing: Since 3D printing is a single molding, the printing time is fast.

CNC machining: programming, processing takes longer than 3D printing.

Process complexity (surface and heterostructure)

3D printing: Machinable complex surfaces, and heterostructure parts, can be molded in one go

CNC Machining: Parts with complex surfaces and heterostructures need to be programmed multiple times, disassembled and processed.

Accuracy and success rate are different

3D Printing: WYSIWYG, high print accuracy, high success rate.

CNC Machining: There is a situation in which a human operation error or a defective jig causes a machining failure.

Complex surface body, different product availability

3D printing: Molded products have disadvantages such as low strength and less wear resistance.

CNC Machining: Molded products have the advantages of high strength and wear resistance.

Why is CNC still the company's first choice?

In the above comparison, 3D printing seems to have more advantages than CNC machining, but in actual circumstances, why is CNC machining still the company's preferred process? The reason is as follows:

1. Economic advantages.

When processing large and heavy parts, CNC machining is much cheaper than 3D printing.

2. Processing standards.

After a long period of development, CNC machining has already formed a complete set of standards in the industry, including spindles, tools and control systems. However, 3D printing does not currently have such a molding standard.

3. Recognition.

Many companies are completely unfamiliar with 3D printing. Because they are unfamiliar with and do not trust this process, they often choose CNC machining that they are familiar with and understand.