Application range and technical parameters of diamond turning

Early diamond turning is mainly used for processing non-ferrous metals such as uranium membered oxygen or an aluminum alloy. Its main products are mirrors in various optical systems, such as the main mirror of radio telescopes, mirrors in LiDA (laser detection) systems, and mirrors in laser cutting machines. During the arms race between the East and the West, the demand for various infrared optical components has soared. Diamond turning can process various infrared optical materials such as germanium, silicon, ZnS and ZnSe. The shape of the workpiece is mostly aspherical, which greatly reduces the number of optical components. Because of the low transmittance of the infrared material, fewer components can improve the light transmission performance of the optical system, and also save expensive infrared materials.

In everyday consumer products, diamond turning is often used to process plexiglass and various plastics. Examples of applications include large projection television screens, plastic lenses for cameras, and resin contact lens lenses.

In mass-produced products, optical components are often formed by extrusion or injection molding. The cavity used for forming is mostly done by diamond turning. In addition to ultra-high strength nickel steel, the cavity material also has tool steel and ceramics. Ultra-high-strength nickel steel is the most widely used material in press forming because it meets the hardness requirements of the mold and can be used to cut the best shape accuracy and surface quality. When machining tool steel with diamond tools, the tool is prone to chemical wear because the carbon in the tool steel reacts with the diamond. Therefore, an ultrasonic vibration device should be attached to the tool holder at this time, or a cubic boron nitride tool should be used for processing.

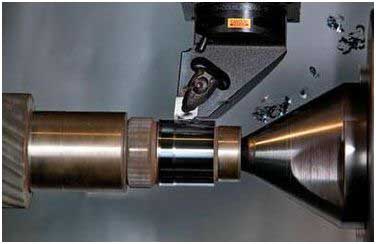

When a workpiece having a diameter of 100 mm or less is turned by diamond, the shape error can be controlled to be 0.1 μm or less. In addition to the cutting parameters and machine characteristics, the surface roughness of the workpiece depends on the characteristics of the material. The surface roughness of most diamond-turnable materials can reach Rq1 ~ 5nm.

The parameters of a diamond turned tool are similar to mirror milling. Metal materials are often processed with zero-degree rake angle tools, and infrared materials and brittle materials are processed with negative rake angle tools.

The cutting parameters for diamond turning are based on the material of the workpiece and the characteristics of the machine. Usually the spindle speed is lower than 2000r/min, and individual can reach 5000r/min. Contact