Application of Hot Stamping Forming Technology in Automobile Manufacturing Industry

With the rapid development of the automobile industry and the increase in the number of holdings, the increase in fuel consumption and CO2 emissions is very rapid. Therefore, the energy conservation and emission reduction of the automotive industry cannot be delayed. The fuel consumption of a car is linearly related to the weight of the car. Take a passenger car as an example. Every 10% drop in car weight, fuel consumption and emissions fall by 6% to 8%. Automobile lightweighting is an important means of energy conservation and emission reduction.

Another issue with the development of the automotive industry is safety. In order to ensure the safety of automobiles, high collision energy absorbing materials or thicker materials must be used to increase the quality of the car. Although this can improve safety, there are contradictions with the fuel consumption regulations and energy conservation and emission reduction. It is necessary to reduce the weight and ensure the safety of vehicles. An effective means is the application of high-strength steel and ultra-high-strength steel. However, the application of high-strength steel has brought difficulties in forming, low mold life, and large rebound. Hot stamping is an effective technique for obtaining ultra-high strength components, which can effectively reduce springback and ensure die life and reasonable price. When the tensile strength is high, forming techniques such as stamping and roll pressing are difficult to form. With ultra-high strength components with tensile strengths above 1200 MPa, hot stamping is almost the only viable technology path. It is in this context that hot stamping technology has rapidly expanded its application in the automotive industry along with the development of the automotive industry and the strict implementation of various regulations.

At present, hot stamping forming materials mainly use 22MnB5. China Automotive Engineering Research Institute and Laiwu Iron and Steel Co., Ltd. have developed components of carbon (C: 0.22% to 0.25%), manganese (Mn: 0.8% to 1.2%), molybdenum (Mo: 0.10% to 0.12%), and boron (B≥ 0.005%) hot stamping steel. The critical cooling rate of the steel is significantly reduced, which is conducive to the implementation of the process. The steel has good oxidation resistance and also has good toughness matching.

Hot stamping began to develop in China since 2000, but initially the equipment of the production line was mostly imported from abroad. After 2010, Chinese universities, such as Huazhong University of Science and Technology, began to establish independent hot stamping test production lines.

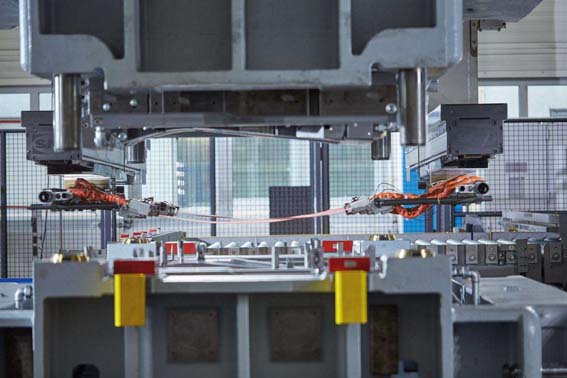

The China Automotive Engineering Research Institute and Huazhong University of Science and Technology adopted a multi-layer box furnace heating method in the introduction line. The use of fast robots to transfer the workpiece, fast hydraulic press hot stamping, the annual production of up to 1 million punches or more, currently running well.

Huazhong University of Science and Technology and China Automotive Engineering Research Institute have established a hot stamping production line with independent intellectual property rights based on independent research and development achievements. The production line features high-efficiency, energy-saving and flexible intelligence. The electric servo press is used for the first time, and the accuracy and accuracy of the action is higher than that of the hydraulic press. The heating furnace used is a multi-layer box furnace, and its manufacturing process level and structure are superior to the advanced level in foreign countries. This production line has the characteristics of small area, small investment, and high cost performance, and has the advantages of energy saving and emission reduction, and has broad application prospects.

At present, the total number of hot stamping production lines in the world exceeds 180. In contrast, China still has a big gap. With the continuous development of hot stamping technology, the number of domestic hot stamping production lines will surely increase. It can be imagined that, with the development of lightweight cars in China, hot stamping production lines will have a lot of room for development in China.