Stamping shrapnel: Widely used in machinery and equipment manufacturing, electronics, electrical appliances, computers, mobile phone cards, mobile phone antenna, earphone voice socket, Inserting piece, micro motors, sensors, automotive instrument touch switches, medical equipment, PCB shields, etc.

(2) can be stored and to output energy as a driving force, for example, mobile phone card shrapnel and mobile phone antenna shrapnel and so on.

(3) Energy that can absorb vibration and impact, for example, the buffer shrapnel in the car and the train compartment and the shock shrapnel in the coupling.

(4) As a component of force measurement, for example, dynamometers and steelyard shrapnel and so on.

The ratio of the load and deformation of the shrapnel is called the stiffness of the shrapnel. The greater the stiffness, the harder the shrapnel.

According to the nature of stress, shrapnel can be divided into compressed shrapnel, curved shrapnel, and so on.

If divided by shape, it can be divided into shapes such as S type, C type, round type, Z type, scoop type and so on.

Hardware shrapnel use matters needing attention

1, in order to avoid repeated impact damage, please use the initial amount of compression.

2, metal shrapnel use, because the contact surface is not stable, more likely to produce bending.

3, when the metal shrapnel nests inside and outside,

Springs are damaged by wear caused by internal and external disturbances.

4, a combination of load, when the difference between the relatively low stiffness of the spring stress concentration occurs, can reduce the life of the product.

5. The hardware spring mounting surface should be very smooth and perpendicular to the spring axis of the mounting surface to avoid localized loads.

What is the function of metal stamping shrapnel?

(1) It is possible to control mechanical movements, such as valve shrapnel in internal combustion engines and control shrapnel in clutches.(2) can be stored and to output energy as a driving force, for example, mobile phone card shrapnel and mobile phone antenna shrapnel and so on.

(3) Energy that can absorb vibration and impact, for example, the buffer shrapnel in the car and the train compartment and the shock shrapnel in the coupling.

(4) As a component of force measurement, for example, dynamometers and steelyard shrapnel and so on.

The ratio of the load and deformation of the shrapnel is called the stiffness of the shrapnel. The greater the stiffness, the harder the shrapnel.

According to the nature of stress, shrapnel can be divided into compressed shrapnel, curved shrapnel, and so on.

If divided by shape, it can be divided into shapes such as S type, C type, round type, Z type, scoop type and so on.

|

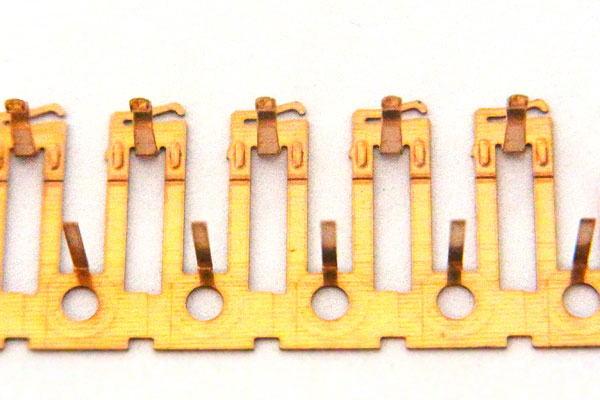

Stamped gold plated shrapnel

[Specifications] 21.2*6.8*0.2MM [Specifications] 21.2*6.8*0.2MM[Material] Stainless steel [process] blanking - bending - forming - plating - inspection packaging [Scope of application] charger, remote control [Custom processing] Yes [surface treatment] gold plating |

|

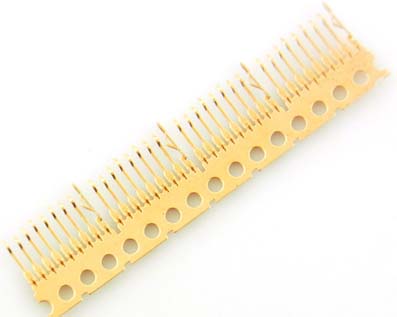

Stamped battery shrapnel

[Specifications] 9.8*10*8.5*0.3mm [Specifications] 9.8*10*8.5*0.3mm[material] iron [Technology] Blanking - Bending - Forming - Rivet Springs - Plating - Inspection Packaging [surface treatment] nickel plating [Applicable range] Remote controller [Custom processing] Yes |

|

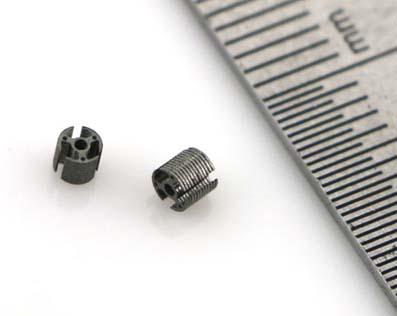

Mobile phone motor shrapnel

[Specifications] 11.2*6.8*0.2MM [Specifications] 11.2*6.8*0.2MM[Material] Stainless steel [process] blanking - bending - forming - plating - inspection packaging [Scope of application] motor shrapnel, mobile phone [Custom processing] Yes [surface treatment] gold plating |

|

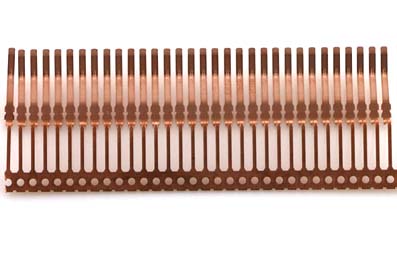

Stamping switch shrapnel

Specifications: 15.1*51.3*1.0(mm) Specifications: 15.1*51.3*1.0(mm)Material: Electrolysis board Process: Blanking - Bending - Forming - Cleaning - Inspection Packaging Scope of application: Industrial power supply Manufacturing detailed parameters: 1, the demand for metal shrapnel color. 2, the demand for metal shrapnel impedance. 3, to determine the shape of the chosen metal shrapnel, the diameter, the raw material, the intensity and the number and needs of life feel. 4, the need for metal shrapnel size tolerances (die tolerance is usually within 0.1MM, laser public service is usually about 0.2MM). |

Hardware shrapnel use matters needing attention

1, in order to avoid repeated impact damage, please use the initial amount of compression.

2, metal shrapnel use, because the contact surface is not stable, more likely to produce bending.

3, when the metal shrapnel nests inside and outside,

Springs are damaged by wear caused by internal and external disturbances.

4, a combination of load, when the difference between the relatively low stiffness of the spring stress concentration occurs, can reduce the life of the product.

5. The hardware spring mounting surface should be very smooth and perpendicular to the spring axis of the mounting surface to avoid localized loads.