Project

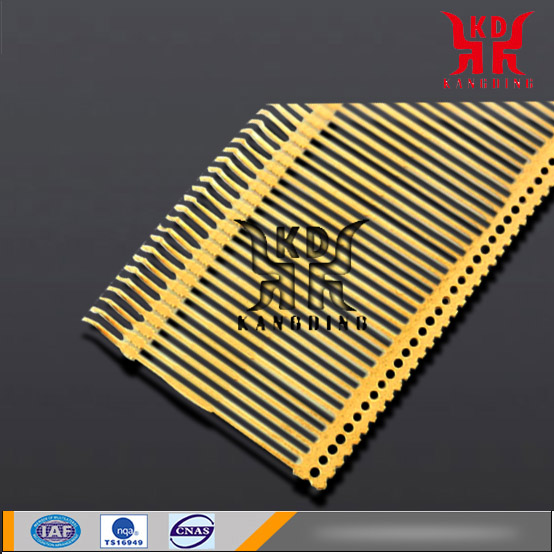

The metal shrapnel is a stamped part, the material is made of heat-treated stainless steel or manganese. It is an important part of the switch. With the continuity of the metal dome, it acts as a good switch between the operator and the product. at the same time, using the stable resilience of the metal dome (automatically returning after pressing), and long life, to provide operators with excellent tactile feedback.

Stamping shrapnel, lead stamping dies, metal shrapnel, connector shrapnel, switch shrapnel, metal shrapnel, terminal shrapnel, precision shrapnel, stainless steel shrapnel

Technology

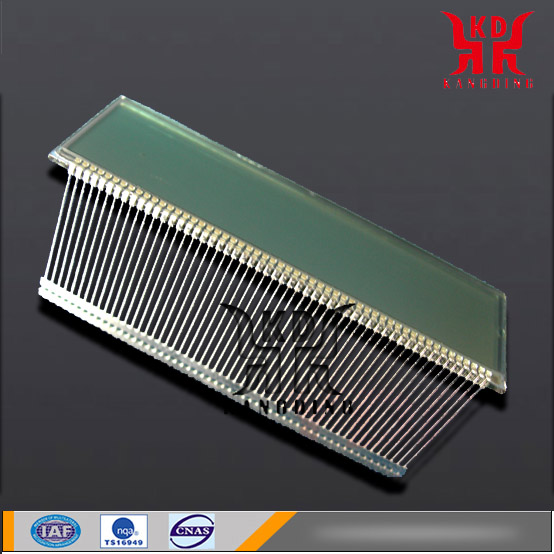

1, metal shrapnel is an important part of various electronic products (mobile phones, connectors, cars, etc.), made of copper, iron, stainless steel and other materials. Plating silver, nickel. Installation. When the battery shrapnel on the conductive film is pressed, The central point of the shrapnel touches the PCB board to form a loop. Current through. It has a strong conduction, good feel and so on.

2, Metal shrapnel production process:

A special process for processing metal materials into parts through cold stamping of stamping dies. Stamping, using the mold installed on the press to apply pressure on the material, causing it to separate or plastic deformation, so as to obtain a stamping method of the required shrapnel parts.

3, metal shrapnel as an important hardware component in the electronic system, has a large amount of use, and a wide variety of metal battery shrapnel production of the original hand-made, gradually moving toward mechanical automation, at the same time, metal shrapnel technology performance is also walking up the trend.

4, metal shrapnel heat treatment can improve the surface hardness, wear resistance and contact fatigue strength, improve the toughness of the core. Metal shrapnel heat treatment can be divided into surface quenching tempering heat treatment and chemical heat treatment two. Surface quenching and tempering heat treatment is usually performed by induction heating or flame heating. The chemical heat treatment is to make the surface of the workpiece penetrate one or more chemical elements of atoms, thereby changing the surface of the chemical composition, organization and performance. The main technical parameters are surface hardness, local hardness and effective hardened layer depth.

Application

Metal shrapnel stamping (also known as metaldome, snapdome), Typical materials are ultra-thin (0.05mm-0.1mm thickness) and ultra-thick (generally higher hardness) stainless steel 301 or 304.

Metal shrapnel stamping is an important part of the switch. Metal shrapnel stamping is mainly used in membrane switch, contact switch, PCB board, FPC board, medical equipment and other products.

General conventional metal shrapnel stamping, according to its different shapes are divided into: round metal shrapnel stamping, cross-shaped metal shrapnel stamping, triangular metal shrapnel stamping, oval metal shrapnel stamping. Diameters range from 3mm to 20mm and strengths from 100g to 600gf. Of course, if you have special requirements to make according to your drawings, there is no problem. Metal shrapnel has a wide range of applications, including mobile phone cards, mobile phone antennas, earphone voice receivers, patch cards, micro motors, sensors, automotive instrument touch switches, medical equipment, and PCB shields.

Material

Generally used copper, iron, stainless steel, manganese and other materials, the product's heat resistance, quenching, corrosion resistance, fatigue strength and elasticity limit and many other factors is the reference for selection of elastic sheet material.

1.excellent surface quality, good brightness

2. Has strong corrosion resistance

3. High tensile strength and fatigue resistance

4. Stable chemical composition, pure steel, low content of inclusions

applicability

1. Control the movement of machinery, such as the valve shrapnel in the internal combustion engine, the control shrapnel in the clutch and so on.

2. Absorb vibration and impact energy, such as buffer springs in cars, train cars, shock absorbing shrapnel in couplings, etc.

3. The storage and output of energy as a power, such as the shrapnel in the clock and the shrapnel in the firearm.

4. As a force measuring element, such as the force gauge, shrapnel in the shrapnel and so on.

Product Categories

Processing methods:

Stretching parts, Compression parts, Twisted pieces, Scroll parts, Spiral parts Etc.

Shapes are mostly S-type, C-type, round, Z-type, spoon-type, precision connectors, motor shrapnel, automotive terminals, medical terminals, shrapnel processing and other consumer electronics products.

The metal shrapnel is a stamped part, the material is made of heat-treated stainless steel or manganese. It is an important part of the switch. With the continuity of the metal dome, it acts as a good switch between the operator and the product. at the same time, using the stable resilience of the metal dome (automatically returning after pressing), and long life, to provide operators with excellent tactile feedback.

Stamping shrapnel, lead stamping dies, metal shrapnel, connector shrapnel, switch shrapnel, metal shrapnel, terminal shrapnel, precision shrapnel, stainless steel shrapnel

Technology

1, metal shrapnel is an important part of various electronic products (mobile phones, connectors, cars, etc.), made of copper, iron, stainless steel and other materials. Plating silver, nickel. Installation. When the battery shrapnel on the conductive film is pressed, The central point of the shrapnel touches the PCB board to form a loop. Current through. It has a strong conduction, good feel and so on.

2, Metal shrapnel production process:

A special process for processing metal materials into parts through cold stamping of stamping dies. Stamping, using the mold installed on the press to apply pressure on the material, causing it to separate or plastic deformation, so as to obtain a stamping method of the required shrapnel parts.

3, metal shrapnel as an important hardware component in the electronic system, has a large amount of use, and a wide variety of metal battery shrapnel production of the original hand-made, gradually moving toward mechanical automation, at the same time, metal shrapnel technology performance is also walking up the trend.

4, metal shrapnel heat treatment can improve the surface hardness, wear resistance and contact fatigue strength, improve the toughness of the core. Metal shrapnel heat treatment can be divided into surface quenching tempering heat treatment and chemical heat treatment two. Surface quenching and tempering heat treatment is usually performed by induction heating or flame heating. The chemical heat treatment is to make the surface of the workpiece penetrate one or more chemical elements of atoms, thereby changing the surface of the chemical composition, organization and performance. The main technical parameters are surface hardness, local hardness and effective hardened layer depth.

Application

Metal shrapnel stamping (also known as metaldome, snapdome), Typical materials are ultra-thin (0.05mm-0.1mm thickness) and ultra-thick (generally higher hardness) stainless steel 301 or 304.

Metal shrapnel stamping is an important part of the switch. Metal shrapnel stamping is mainly used in membrane switch, contact switch, PCB board, FPC board, medical equipment and other products.

General conventional metal shrapnel stamping, according to its different shapes are divided into: round metal shrapnel stamping, cross-shaped metal shrapnel stamping, triangular metal shrapnel stamping, oval metal shrapnel stamping. Diameters range from 3mm to 20mm and strengths from 100g to 600gf. Of course, if you have special requirements to make according to your drawings, there is no problem. Metal shrapnel has a wide range of applications, including mobile phone cards, mobile phone antennas, earphone voice receivers, patch cards, micro motors, sensors, automotive instrument touch switches, medical equipment, and PCB shields.

Material

Generally used copper, iron, stainless steel, manganese and other materials, the product's heat resistance, quenching, corrosion resistance, fatigue strength and elasticity limit and many other factors is the reference for selection of elastic sheet material.

1.excellent surface quality, good brightness

2. Has strong corrosion resistance

3. High tensile strength and fatigue resistance

4. Stable chemical composition, pure steel, low content of inclusions

applicability

1. Control the movement of machinery, such as the valve shrapnel in the internal combustion engine, the control shrapnel in the clutch and so on.

2. Absorb vibration and impact energy, such as buffer springs in cars, train cars, shock absorbing shrapnel in couplings, etc.

3. The storage and output of energy as a power, such as the shrapnel in the clock and the shrapnel in the firearm.

4. As a force measuring element, such as the force gauge, shrapnel in the shrapnel and so on.

Product Categories

Processing methods:

Stretching parts, Compression parts, Twisted pieces, Scroll parts, Spiral parts Etc.

Shapes are mostly S-type, C-type, round, Z-type, spoon-type, precision connectors, motor shrapnel, automotive terminals, medical terminals, shrapnel processing and other consumer electronics products.

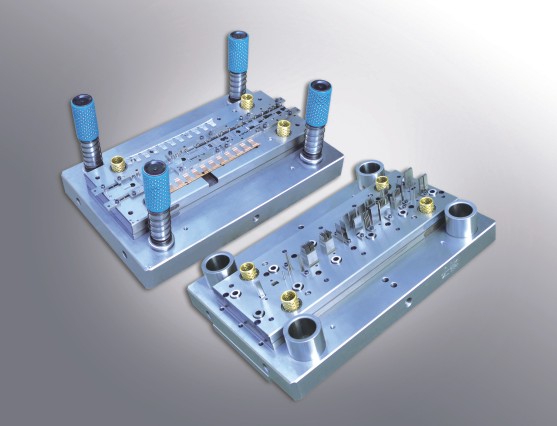

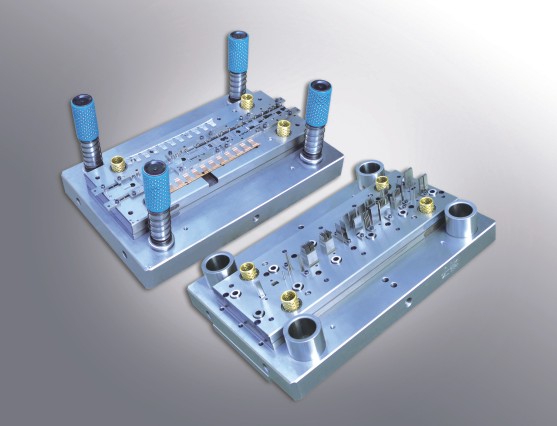

Shrapnel die design example

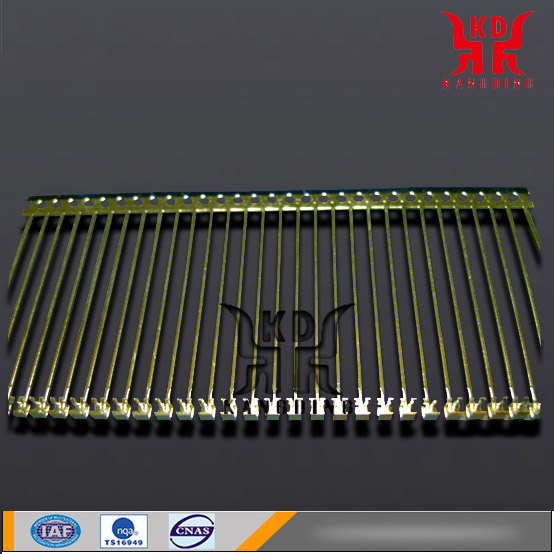

Card line shrapnel is a commonly used metal component in automobiles.

It is mainly used to centrally clamp together the wires scattered in the car. The structure of the snap-in spring is integrally formed, and the cross-section is in a U-shape. The bottom of the U-shape is a straight section and the left and right arms are wavy.

At present, the method for producing a snap-in spring is to first roll both sides of a straight-line snap-shot blank into a wavy shape, and then the operator then bends the blank into a "U" shape; The disadvantage of the above operation method is that it is easy for the finished product to fail to meet the product standards due to the improper operation of the worker. Resulting in an increased need to manually trim the size of those do not meet the requirements of the product, this not only improves the work intensity of workers, It also increases the company's production costs.

The punching die of the wire spring is composed of an upper die holder and a lower die holder, and a lower template fixed on the top of the lower die holder and provided with a chamber in the middle. A punch that is fixed to the bottom of the upper die holder and can extend into the chamber, in the bottom of the cavity of the lower die seat, there are two lower mold inserts arranged symmetrically in left and right sides.

There is an internal release between the two die inserts.The inner upper and lower sides of the inner hinge are respectively hinged with a movable die. The outer side of the movable die abuts the lower mold insert on the same side as the movable die.

The inner detachment moves up and down between the two lower mold inserts by the ejector mechanism, in the open state, The inner surface of the inner part is located above the chamber in the lower template. And the inner surface of the inner detachment and the tops of the movable dies on both sides together form a workpiece placement surface; When the inside descends down to the bottom of the chamber in the lower template, The inner surface of the inner release and the inner side of the movable concave film on the left and right sides together define a molding cavity.

It is mainly used to centrally clamp together the wires scattered in the car. The structure of the snap-in spring is integrally formed, and the cross-section is in a U-shape. The bottom of the U-shape is a straight section and the left and right arms are wavy.

At present, the method for producing a snap-in spring is to first roll both sides of a straight-line snap-shot blank into a wavy shape, and then the operator then bends the blank into a "U" shape; The disadvantage of the above operation method is that it is easy for the finished product to fail to meet the product standards due to the improper operation of the worker. Resulting in an increased need to manually trim the size of those do not meet the requirements of the product, this not only improves the work intensity of workers, It also increases the company's production costs.

The punching die of the wire spring is composed of an upper die holder and a lower die holder, and a lower template fixed on the top of the lower die holder and provided with a chamber in the middle. A punch that is fixed to the bottom of the upper die holder and can extend into the chamber, in the bottom of the cavity of the lower die seat, there are two lower mold inserts arranged symmetrically in left and right sides.

There is an internal release between the two die inserts.The inner upper and lower sides of the inner hinge are respectively hinged with a movable die. The outer side of the movable die abuts the lower mold insert on the same side as the movable die.

The inner detachment moves up and down between the two lower mold inserts by the ejector mechanism, in the open state, The inner surface of the inner part is located above the chamber in the lower template. And the inner surface of the inner detachment and the tops of the movable dies on both sides together form a workpiece placement surface; When the inside descends down to the bottom of the chamber in the lower template, The inner surface of the inner release and the inner side of the movable concave film on the left and right sides together define a molding cavity.