Mechanical Milling Processing Custom Part Titanium TC4

Keywords: Mechanical Processing, TC4 titanium parts, TC4 titanium physical properties, TC4 titanium chemical properties, TC4 titanium parts machining design, Custom Titanium Part, Custom TC4 Turning tool

First, processing characteristics:

TC4 has the following special physical/chemical properties:

1. The thermal conductivity of TC4 is low, which makes the workpiece and tool temperature higher during the machining process;

2, The low modulus of elasticity of TC4 causes a large rebound after deformation under load, which causes the machining error of the workpiece to increase, and the torque of the cutting tool increases, the cutting edge wears fast, and the durability decreases.

3, TC4 has low hardness and high chemical activity, which results in dissolution and diffusion between TC4 and cutting tools at high temperature, resulting in sticking knife, burning knife, breaking knife and other phenomena.

Based on the above analysis, the processing technology of TC4 should include the following principles:

1, Due to the low thermal conductivity of TC4, low plasticity and high work hardening tendency. In the processing, the cutting force is large, and the cutting temperature is high, which causes the tool to be easy to wear and the life is reduced. Therefore, the tool should choose materials with good wear resistance, high thermal hardness and enough toughness. YG8, YG8W and YG10H should be used in rough machining and YG8W or YP15 (YGRM) should be used in finish machining.

2. Optimizing cutting conditions, including machine tool-fixture-tool system rigidity is good.

3. Choose a reasonable amount of cutting. Under normal circumstances, the cutting speed should be low, the cutting depth should be large, and the cutting can not be stopped during the cutting process.

4. Improve chip control and ensure reliable chip breaking measures.

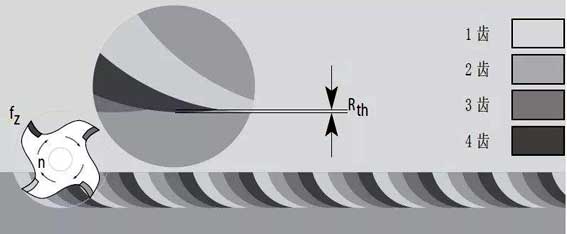

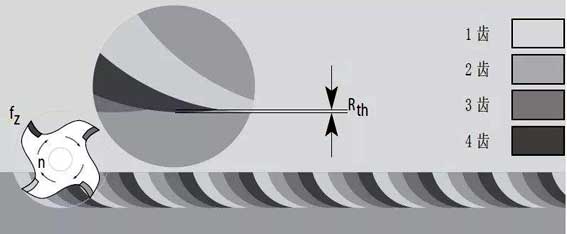

Second, the experimental design

Considering the above factors, this process studies the single-factor test and multi-factor orthogonal test to study the cutting process of TC4, and analyze the surface integrity of the processed samples.

The evaluation indicators mainly include: surface roughness, processing hardness, residual stress and microstructure.

(1) Single factor test:

Referring to the range of cutting parameters in actual production, the range of horizontal variation of each factor in this experiment is set as follows:

(1) The milling speed level is changed to 40, 80, 100, 120, 140 m/min, the feed rate is 50 mm/min, the axial milling depth is 1.5 mm, and the radial milling depth is 28 mm.

(2) The positive horizontal change of each tooth feed is 0.05, 0.07, 0.09, 0.11, 0.13mm, the milling speed is 40mm/min, the axial milling depth is 0.9mm, and the radial milling depth is 8mm;

(3) The axial milling depth changes to 0.4, 0.6, O.8, 1.0, 1.2, 1.5 mm, maintaining a milling speed of 40 mm/min, a feed rate of 40.7 mm/min, and a radial milling depth of 8 mm:

(4) The radial milling depth is changed to 4, 6, 8, 10, 12 5, 14, 16 mm, the milling speed is k=40 mm/min, the feed rate is 40.7 mm/min, and the axial milling depth is 1 mm.

Through the above tests, you can understand the influence of milling parameters on physical quantities such as milling force, milling temperature and surface quality.

(B), multi-factor orthogonal test.

This process research uses orthogonal design L16 to study the milling process of TC4. The specific parameters are as follows:

The milling parameters and horizontal coding are:

Orthogonal test table:

Through the above orthogonal test, the degree of influence of each processing parameter on the surface integrity of the machine can be understood, and the best processing technology can be obtained.

Third, analysis and evaluation:

The surface roughness is measured by a white light interferometer on the machined surface. Each of the tests was carried out by taking 5 places in the milling direction.

The addition of hardening is the result of the combined effect of the thermal coupling non-uniform stress field on the machined surface of the workpiece during the cutting process, which is related to the cutting conditions and the mechanical properties of the workpiece. In this work, the influence of milling factors on work hardening and hardening law were studied by measuring the hardness of the surface layer after TC4 milling. The hardness of the machined surface was measured by a Vickers microhardness tester, and the degree of work hardening was obtained by comparing the surface hardness with the hardness of the unmachined surface. 5 samples per milling direction for measurement.

The TC4 material is very sensitive to stress conditions, especially the residual stress of the machined surface and its distribution state is very important for the rational use of the component.

The residual stress of the machined surface has the difference between the residual tensile stress and the residual compressive stress. The residual tensile stress reduces the fatigue strength and service life of the part, and the residual compressive stress sometimes improves the fatigue strength and service life of the part. The uneven distribution of residual stress on each part of the machined surface will also cause deformation of the workpiece, affecting the shape and dimensional accuracy of the workpiece. Therefore, the research work uses X-ray method to study the surface residual stress and its distribution of TC4TC4 material at high speed milling. The microstructure is cut by wire cutting method, and the cross section of the vertical feeding direction is the observation surface. After polishing, the appropriate etching solution was selected for surface corrosion and observed by SEM.

First, processing characteristics:

TC4 has the following special physical/chemical properties:

1. The thermal conductivity of TC4 is low, which makes the workpiece and tool temperature higher during the machining process;

2, The low modulus of elasticity of TC4 causes a large rebound after deformation under load, which causes the machining error of the workpiece to increase, and the torque of the cutting tool increases, the cutting edge wears fast, and the durability decreases.

3, TC4 has low hardness and high chemical activity, which results in dissolution and diffusion between TC4 and cutting tools at high temperature, resulting in sticking knife, burning knife, breaking knife and other phenomena.

Based on the above analysis, the processing technology of TC4 should include the following principles:

1, Due to the low thermal conductivity of TC4, low plasticity and high work hardening tendency. In the processing, the cutting force is large, and the cutting temperature is high, which causes the tool to be easy to wear and the life is reduced. Therefore, the tool should choose materials with good wear resistance, high thermal hardness and enough toughness. YG8, YG8W and YG10H should be used in rough machining and YG8W or YP15 (YGRM) should be used in finish machining.

2. Optimizing cutting conditions, including machine tool-fixture-tool system rigidity is good.

3. Choose a reasonable amount of cutting. Under normal circumstances, the cutting speed should be low, the cutting depth should be large, and the cutting can not be stopped during the cutting process.

4. Improve chip control and ensure reliable chip breaking measures.

Second, the experimental design

Considering the above factors, this process studies the single-factor test and multi-factor orthogonal test to study the cutting process of TC4, and analyze the surface integrity of the processed samples.

The evaluation indicators mainly include: surface roughness, processing hardness, residual stress and microstructure.

(1) Single factor test:

Referring to the range of cutting parameters in actual production, the range of horizontal variation of each factor in this experiment is set as follows:

(1) The milling speed level is changed to 40, 80, 100, 120, 140 m/min, the feed rate is 50 mm/min, the axial milling depth is 1.5 mm, and the radial milling depth is 28 mm.

(2) The positive horizontal change of each tooth feed is 0.05, 0.07, 0.09, 0.11, 0.13mm, the milling speed is 40mm/min, the axial milling depth is 0.9mm, and the radial milling depth is 8mm;

(3) The axial milling depth changes to 0.4, 0.6, O.8, 1.0, 1.2, 1.5 mm, maintaining a milling speed of 40 mm/min, a feed rate of 40.7 mm/min, and a radial milling depth of 8 mm:

(4) The radial milling depth is changed to 4, 6, 8, 10, 12 5, 14, 16 mm, the milling speed is k=40 mm/min, the feed rate is 40.7 mm/min, and the axial milling depth is 1 mm.

Through the above tests, you can understand the influence of milling parameters on physical quantities such as milling force, milling temperature and surface quality.

(B), multi-factor orthogonal test.

This process research uses orthogonal design L16 to study the milling process of TC4. The specific parameters are as follows:

The milling parameters and horizontal coding are:

|

Milling depth (mm) |

Milling speed (m/min) |

Feed per tooth (mm) |

Milling width (mm) |

|

| Upper Level (3) | 1.4 | 120 | 0.14 | 14 |

| Subordinate level (1) | 1 | 100 | 0.1 | 11 |

| Next level (-1) | 0.6 | 80 | 0.06 | 18 |

| Lower level (3) | 0.2 | 60 | 0.02 | 5 |

Orthogonal test table:

|

Milling depth (mm) |

Milling speed (m/min) |

Feed per tooth (mm) |

Milling width (mm) |

|

| 1 | 1.4 | 100 | 0.06 | 11 |

| 2 | 1.4 | 80 | 0.14 | 5 |

| 3 | 1.4 | 120 | 0.02 | 8 |

| 4 | 1.4 | 60 | 0.1 | 14 |

| 5 | 1 | 60 | 0.06 | 8 |

| 6 | 1 | 120 | 0.14 | 14 |

| 7 | 1 | 80 | 0.02 | 11 |

| 8 | 1 | 100 | 0.1 | 5 |

| 9 | 0.6 | 60 | 0.14 | 11 |

| 10 | 0.6 | 120 | 0.06 | 5 |

| 11 | 0.6 | 80 | 0.1 | 8 |

| 12 | 0.6 | 100 | 0.02 | 14 |

| 13 | 0.2 | 100 | 0.14 | 8 |

| 14 | 0.2 | 80 | 0.06 | 14 |

| 15 | 0.2 | 120 | 0.1 | 11 |

| 16 | 0.2 | 60 | 0.02 | 5 |

Through the above orthogonal test, the degree of influence of each processing parameter on the surface integrity of the machine can be understood, and the best processing technology can be obtained.

Third, analysis and evaluation:

The surface roughness is measured by a white light interferometer on the machined surface. Each of the tests was carried out by taking 5 places in the milling direction.

The addition of hardening is the result of the combined effect of the thermal coupling non-uniform stress field on the machined surface of the workpiece during the cutting process, which is related to the cutting conditions and the mechanical properties of the workpiece. In this work, the influence of milling factors on work hardening and hardening law were studied by measuring the hardness of the surface layer after TC4 milling. The hardness of the machined surface was measured by a Vickers microhardness tester, and the degree of work hardening was obtained by comparing the surface hardness with the hardness of the unmachined surface. 5 samples per milling direction for measurement.

The TC4 material is very sensitive to stress conditions, especially the residual stress of the machined surface and its distribution state is very important for the rational use of the component.

The residual stress of the machined surface has the difference between the residual tensile stress and the residual compressive stress. The residual tensile stress reduces the fatigue strength and service life of the part, and the residual compressive stress sometimes improves the fatigue strength and service life of the part. The uneven distribution of residual stress on each part of the machined surface will also cause deformation of the workpiece, affecting the shape and dimensional accuracy of the workpiece. Therefore, the research work uses X-ray method to study the surface residual stress and its distribution of TC4TC4 material at high speed milling. The microstructure is cut by wire cutting method, and the cross section of the vertical feeding direction is the observation surface. After polishing, the appropriate etching solution was selected for surface corrosion and observed by SEM.