Metal Parts Products UV Paint Curing Processing

Abbreviation for Ultraviolet Curing Paint, that is UV light curing paint, also called light-initiated paint, light-cured coating. It is applied to the surface of metal parts by automatic roller coating and shower coating. Under the irradiation of ultraviolet light, the initiator is decomposed to generate free radicals, initiate the resin reaction, and instantaneously cure the film. This is the most environmentally friendly paint.

A wear-resistant UV-curable coating made from the following parts by weight of raw materials:

Dicyclopentadiene 2-3,

Glycidyl methacrylate 3-4,

Urethane Acrylate 45-50,

Trimethylolpropane triacrylate 10-12,

Tetrabutylammonium bromide 2-5,

Yttrium oxide 1-2,

Trichloroethyl phosphate 2-3,

Resorcinol diglycidyl ether 1-2,

Isopropyl thioxanthone 3-4,

Benzoin Dimethylether 8-10,

Dispersion aids 4-5.

The present invention uses urethane acrylate as the main material, added cerium oxide, benzoin dimethyl ether, dicyclopentadiene and other plasticizing and reinforcing substances, The resulting coating has a strong adhesion and wear resistance, acid and alkali resistance, corrosion resistance; The UV coating is suitable for many occasions of friction, and can be used as a primer for hardware, zinc alloy, aluminum alloy, stainless steel, vacuum plating coating UV, the coating performance is long-lasting, and the curing speed is fast.

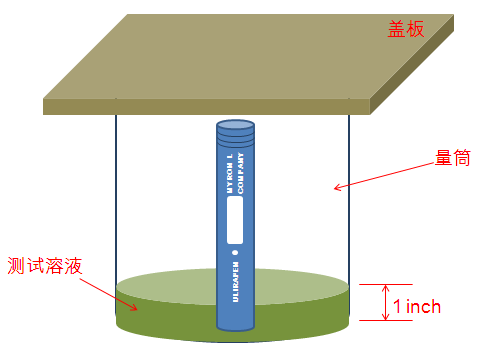

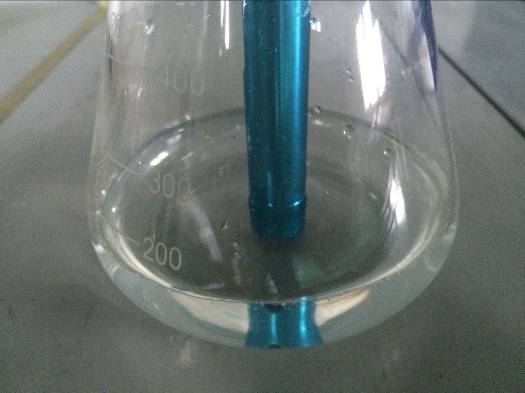

Unlike paints such as PU, PE, and NC, which are named after the film-forming substance, UV lacquers are named after the curing method of the paint. It is automatically roller coated onto the surface of metal parts by machine equipment. Under the irradiation of ultraviolet light (wavelength 320-390 nm), the initiator is caused to decompose, generate radicals, initiate the resin reaction, and instantaneously cure the film.

1 During the production process, the harmful substances in the board are decomposed and dried by a UV light curing machine to make the product more healthy and environmentally friendly.

2. UV paint film is a three-dimensional structure, hardness, good wear resistance, good transparency, product scratch resistance, friction resistance, stand the test of time.

3. The mechanized equipment overcomes the artificial factors in the manual operation, so that the product has small color difference and stable quality.

UV paint is widely used metal parts paint, the main features are:

After a strong UV light curing process, the color is stable, it is timeless and new, and it effectively solves the problem of oxidation fading and color aberration; The mirror effect of the metal product mirror is good, and the paint film is full without orange peel; it is one of the world's more environmentally friendly curing paints; scratch resistant, acid and alkali resistant, and not easily deformed.

UV paint advantages:

1, long pot life

2, excellent yellowing resistance

3, good hardness, high transparency

4, high solid content

5. One of the most environmentally friendly paints

6, high efficiency, low coating costs (normal is half of the conventional coating costs, is dozens of times the conventional coating efficiency).

1, requires UV coating production lines of various types of large equipment investment.

2, to have a sufficient supply of goods in order to meet their production needs. Continuous production can control its efficiency and cost control.

3. The effect of the roller-coating topcoat is slightly worse than that of the PU topcoat product.

4. The roller coating product requires the coated part to be flat.

5. When the number of customers is small, the machines also need to be run, causing a waste of machines and raw materials.