Chip Breaking Problem In CNC Turning

Whether the tool chip breaking is reliable or not has a major impact on normal production and operator safety. In the cutting process, the chipping of the chip will splash and hurt people, and it is easy to damage the machine tool; Long strips of swarf can be wound around the workpiece or the tool, which can easily scratch the workpiece, causing damage to the tool and even affecting worker safety. For automatic machining machines such as CNC machine tools (machining centers), due to the large number of tools and the close connection between the tool holder and the tool, the problem of chip breaking is even more important. As long as the chip breaking of one of the knives is unreliable, it may damage the automatic circulation of the machine tool or even destroy the normal operation of the entire automatic line. Therefore, when designing, selecting or sharpening the tool, the reliability of the chip breaking chip must be considered. For CNC machine tools (machining centers), etc., the following requirements should be met:

Chipping shall not be wound around the tool, the workpiece and its adjacent tools and equipment;

Chipping must not splash to ensure the safety of the operator and the observer;

During finishing, chipping shall not scratch the machined surface of the workpiece and affect the quality of the machined surface;

Ensure the predetermined durability of the tool, not prematurely wear and try to prevent it from being damaged;

When the chipping flows out, it does not hinder the injection of the cutting fluid;

Chipping does not scratch machine rails or other components.

On the basis of meeting the above requirements, different tools have different requirements for the chucking length. For example, the maximum chipping length of a general rough turning steel is about 100 mm; Fine turning should be a little longer. To avoid excessively comminution chipping, because it is easy to embed some important parts of the machine guide rail and tool device (such as the reference surface), which not only requires additional guards, but also brings certain difficulties in clearing the chipping.

One, Classification of chipping shapes

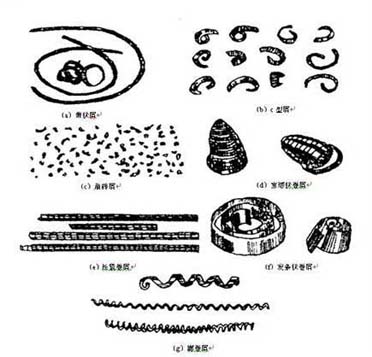

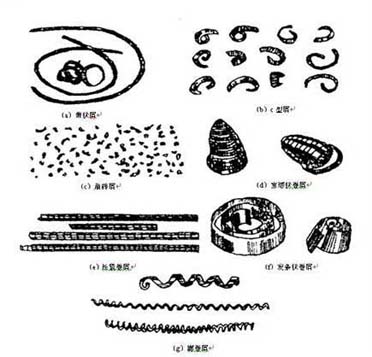

According to the specific conditions of the workpiece material, tool geometry and cutting amount, the chipping shape generally has: Strip-shaped chipping, C-shaped chipping, Chipping chipping, Pagoda volume chipping, Hair strip roll chipping, Long tight screw chipping, Spiral chipping, etc. (see Figure 1).

(1) Strip-shaped chips (see Figure 1a): When cutting plastic metal materials at high speed, if no chip breaking measures are taken, it is easy to form band-shaped chips, which are continuous and often wrap around the workpiece or tool, which is easy to scratch. The surface of the workpiece or the cutting edge of the tool is damaged, and even the person is injured. Therefore, it is necessary to avoid the formation of strip-shaped chips.

However, it is sometimes desirable to obtain strip-shaped chips so that Chipping can be discharged smoothly. For example, when blind holes are placed on a vertical trampoline.

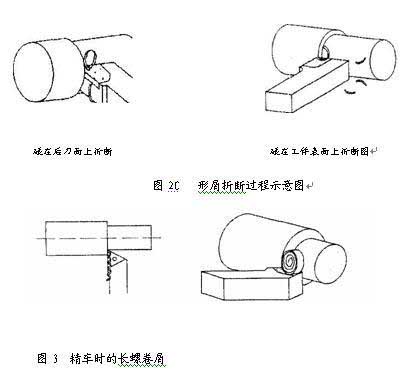

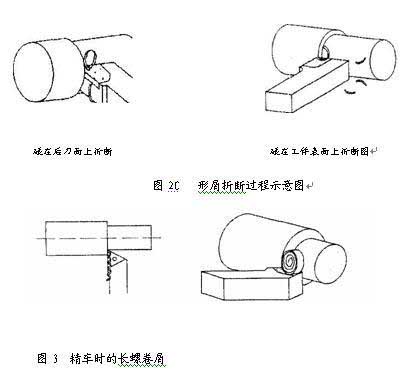

(2) C-shaped swarf (see Figure 1 b): When turning carbon steel and alloy steel materials, C-shaped swarf is easy to form if a turning tool with a chip breaker is used. C-shaped chips have no disadvantages of ribbon chips. However, most of the C-shaped chips are broken by collision with the flank of the turning tool or the surface of the workpiece (see Figure 2). Chipping high frequency breaks and breaks can affect the smoothness of the cutting process, thus affecting the roughness of the machined surface. Therefore, it is generally undesirable to obtain C-shaped chips during finishing. It is desirable to obtain long spiral swarf (see Figure 3) to make the cutting process smoother.

(3) Spring roll Chipping (see Figure 1f):

On a heavy-duty lathe, the steel is cut with a large depth of cut and a large feed. The chipping is wide and thick. If C-shaped chips are formed, it is easy to damage the cutting edge and even splash and injure people. Therefore, the arc radius of the groove bottom of the chip breaker is usually increased, so that the chipping into a spring (see FIG. 4) collides and breaks on the machined surface, and falls by its own weight.

(4) long wound up Chipping (See Figure 1e):

The formation process of long tight-rolled chips is relatively stable, and the cleaning is also convenient, which is a good chip shape on a common lathe.

(5) Pagoda roll Chipping [See Figure 1d):

This type of chip is desirable for CNC machining, machine tools, or automatic wire machining because such chipping does not wrap around the tool and workpiece. And cleaning is also convenient.

Chipping shall not be wound around the tool, the workpiece and its adjacent tools and equipment;

Chipping must not splash to ensure the safety of the operator and the observer;

During finishing, chipping shall not scratch the machined surface of the workpiece and affect the quality of the machined surface;

Ensure the predetermined durability of the tool, not prematurely wear and try to prevent it from being damaged;

When the chipping flows out, it does not hinder the injection of the cutting fluid;

Chipping does not scratch machine rails or other components.

On the basis of meeting the above requirements, different tools have different requirements for the chucking length. For example, the maximum chipping length of a general rough turning steel is about 100 mm; Fine turning should be a little longer. To avoid excessively comminution chipping, because it is easy to embed some important parts of the machine guide rail and tool device (such as the reference surface), which not only requires additional guards, but also brings certain difficulties in clearing the chipping.

One, Classification of chipping shapes

According to the specific conditions of the workpiece material, tool geometry and cutting amount, the chipping shape generally has: Strip-shaped chipping, C-shaped chipping, Chipping chipping, Pagoda volume chipping, Hair strip roll chipping, Long tight screw chipping, Spiral chipping, etc. (see Figure 1).

(1) Strip-shaped chips (see Figure 1a): When cutting plastic metal materials at high speed, if no chip breaking measures are taken, it is easy to form band-shaped chips, which are continuous and often wrap around the workpiece or tool, which is easy to scratch. The surface of the workpiece or the cutting edge of the tool is damaged, and even the person is injured. Therefore, it is necessary to avoid the formation of strip-shaped chips.

However, it is sometimes desirable to obtain strip-shaped chips so that Chipping can be discharged smoothly. For example, when blind holes are placed on a vertical trampoline.

(2) C-shaped swarf (see Figure 1 b): When turning carbon steel and alloy steel materials, C-shaped swarf is easy to form if a turning tool with a chip breaker is used. C-shaped chips have no disadvantages of ribbon chips. However, most of the C-shaped chips are broken by collision with the flank of the turning tool or the surface of the workpiece (see Figure 2). Chipping high frequency breaks and breaks can affect the smoothness of the cutting process, thus affecting the roughness of the machined surface. Therefore, it is generally undesirable to obtain C-shaped chips during finishing. It is desirable to obtain long spiral swarf (see Figure 3) to make the cutting process smoother.

(3) Spring roll Chipping (see Figure 1f):

On a heavy-duty lathe, the steel is cut with a large depth of cut and a large feed. The chipping is wide and thick. If C-shaped chips are formed, it is easy to damage the cutting edge and even splash and injure people. Therefore, the arc radius of the groove bottom of the chip breaker is usually increased, so that the chipping into a spring (see FIG. 4) collides and breaks on the machined surface, and falls by its own weight.

(4) long wound up Chipping (See Figure 1e):

The formation process of long tight-rolled chips is relatively stable, and the cleaning is also convenient, which is a good chip shape on a common lathe.

(5) Pagoda roll Chipping [See Figure 1d):

This type of chip is desirable for CNC machining, machine tools, or automatic wire machining because such chipping does not wrap around the tool and workpiece. And cleaning is also convenient.