The price impact of materials on custom high-precision camera housings

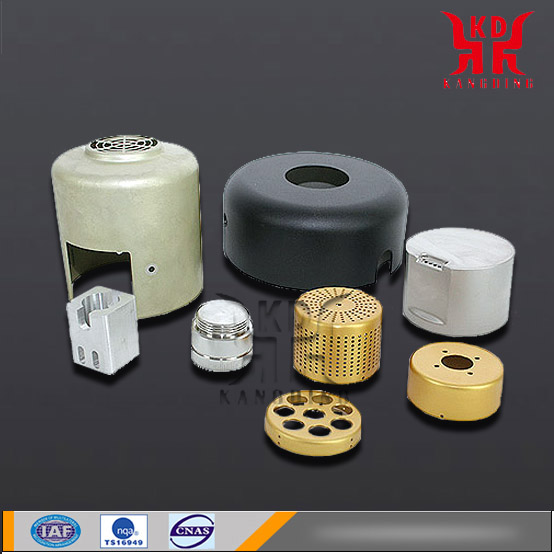

- PRODUCT DETAIL

Professionals know that the internal structure of the camera is infrared led fill light board + sensor chip + lens + cable + dsp processing chip only, very simple. But some cameras, especially HD cameras, have a very large casing. For electronic products, consumers feel that the product is small and beautiful, but is it true for cameras?

The size of the camera housing is affected by heat dissipation and protection. It is understood that the camera casing has a variety of styles, the same casing can hold different movements, different movement accessories are also different. The size of the casing is also made according to the size of the camera movement.

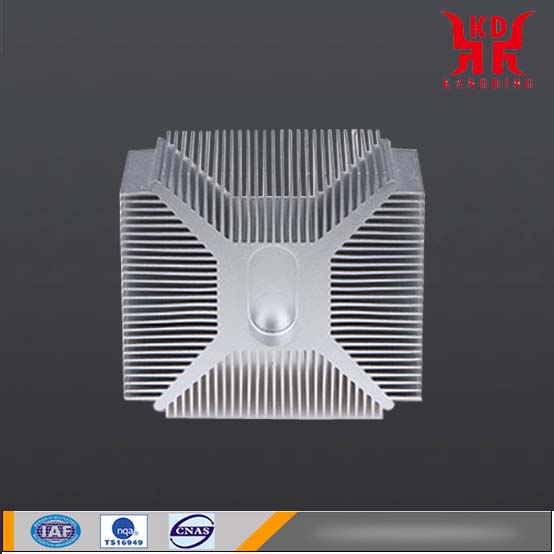

Different kinds of cameras, the material and size of the outer casing are also different. The larger the camera housing, the better the heat dissipation performance. Judging from the current domestic camera market, many domestic cameras are now made of plastic large casings. If the plastic case is to be made small, there is a problem with the heat dissipation of the camera. Because of the limited space, the infrared panel is large and generates a lot of heat; Only the outer shell of the metal can conduct heat to the outer casing to achieve heat dissipation; In the case of a plastic case, if the case is made small, the space is reduced, so that heat cannot be dissipated. For the camera, the heat dissipation of the infrared panel is very important. Because the infrared light board is very sensitive to heat, the temperature is too high, which will cause the LED wavelength to shift; The internal illumination point is permanently disabled; Encapsulation colloid deformation affects light efficiency and other issues. At present, the better heat dissipation is to connect the light board directly to the outer casing, and heat the led light board through the camera housing. And it is better to use the thermal design to analyze and evaluate the heat of the whole machine before designing the camera casing, to reduce the excessive temperature in the later stage and adjust the passive situation of the structure. At present, the low-end products in China still use more plastic shells, which is cheaper, but there is no guarantee in terms of quality. Most cameras sold in the Shenzhen Huaqiangbei professional market are plastic casings. If the plastic case is large, the heat cannot be completely dissipated. In this case, problems will occur in half a year to one year. ”

It is understood that the size of the camera housing not only has an impact on heat dissipation, but also has an important impact on the protection performance.

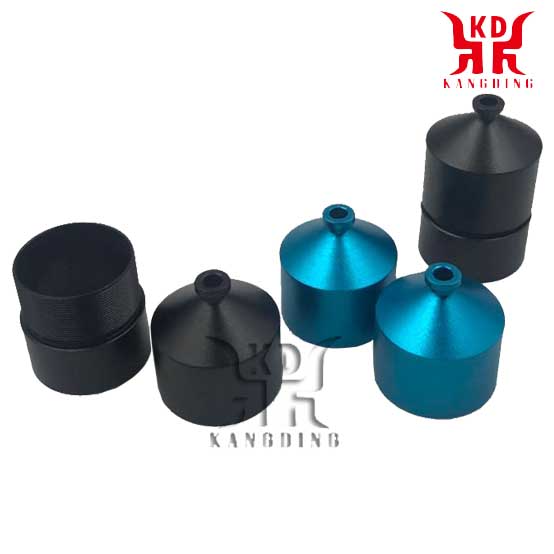

The higher the camera effect, the greater the heat dissipation. The heat dissipation performance of the aluminum alloy is relatively good. If it is used outdoors, the material protection grade of the aluminum alloy is relatively high, and the stability of the large outer casing is also better. And there are many types of cameras, including high-speed balls, one-piece machines, hemispheres, and so on. The size of the outer casing needs to be set according to the type and use. It can be seen that the housing requirements of the camera are different indoors and outdoors. Taking a high-speed dome as an example, if it is used outdoors, the volume of the casing is generally relatively large; If it is a household, it will generally choose a smaller mini camera. Because it is necessary to consider waterproofing, heat dissipation, etc. when installing outdoors, there are relatively few factors considered in the room. In addition, a good shell design, in addition to meet the needs of waterproofing, heat dissipation, but also to deal with infrared leakage and reflection problems. Previously, infrared cameras often showed normal daytime images and no images were seen late. In addition to the infrared light caused by the camera installation environment, the infrared light is directly reflected back into the outer casing; there is a gap around the inside of the outer casing; The glass is not designed with double-ring glass; The sunshade is not blacked out, etc., causing infrared light leakage; Reflecting directly into the casing causes image whitening problems. Therefore, the infrared camera night vision effect is not only limited by the infrared light board, chip, etc., but also affected by the mechanism, which needs to attract enough attention.

0 degree, 12 degree wide angle monitor mini camera housing LED light night vision wide angle camera hardware shell

Waterproof miniature coaxial camera housing for fish detector Front and rear camera housing for the car (18.5mm)

The size of the camera housing is affected by heat dissipation and protection. It is understood that the camera casing has a variety of styles, the same casing can hold different movements, different movement accessories are also different. The size of the casing is also made according to the size of the camera movement.

Different kinds of cameras, the material and size of the outer casing are also different. The larger the camera housing, the better the heat dissipation performance. Judging from the current domestic camera market, many domestic cameras are now made of plastic large casings. If the plastic case is to be made small, there is a problem with the heat dissipation of the camera. Because of the limited space, the infrared panel is large and generates a lot of heat; Only the outer shell of the metal can conduct heat to the outer casing to achieve heat dissipation; In the case of a plastic case, if the case is made small, the space is reduced, so that heat cannot be dissipated. For the camera, the heat dissipation of the infrared panel is very important. Because the infrared light board is very sensitive to heat, the temperature is too high, which will cause the LED wavelength to shift; The internal illumination point is permanently disabled; Encapsulation colloid deformation affects light efficiency and other issues. At present, the better heat dissipation is to connect the light board directly to the outer casing, and heat the led light board through the camera housing. And it is better to use the thermal design to analyze and evaluate the heat of the whole machine before designing the camera casing, to reduce the excessive temperature in the later stage and adjust the passive situation of the structure. At present, the low-end products in China still use more plastic shells, which is cheaper, but there is no guarantee in terms of quality. Most cameras sold in the Shenzhen Huaqiangbei professional market are plastic casings. If the plastic case is large, the heat cannot be completely dissipated. In this case, problems will occur in half a year to one year. ”

It is understood that the size of the camera housing not only has an impact on heat dissipation, but also has an important impact on the protection performance.

The higher the camera effect, the greater the heat dissipation. The heat dissipation performance of the aluminum alloy is relatively good. If it is used outdoors, the material protection grade of the aluminum alloy is relatively high, and the stability of the large outer casing is also better. And there are many types of cameras, including high-speed balls, one-piece machines, hemispheres, and so on. The size of the outer casing needs to be set according to the type and use. It can be seen that the housing requirements of the camera are different indoors and outdoors. Taking a high-speed dome as an example, if it is used outdoors, the volume of the casing is generally relatively large; If it is a household, it will generally choose a smaller mini camera. Because it is necessary to consider waterproofing, heat dissipation, etc. when installing outdoors, there are relatively few factors considered in the room. In addition, a good shell design, in addition to meet the needs of waterproofing, heat dissipation, but also to deal with infrared leakage and reflection problems. Previously, infrared cameras often showed normal daytime images and no images were seen late. In addition to the infrared light caused by the camera installation environment, the infrared light is directly reflected back into the outer casing; there is a gap around the inside of the outer casing; The glass is not designed with double-ring glass; The sunshade is not blacked out, etc., causing infrared light leakage; Reflecting directly into the casing causes image whitening problems. Therefore, the infrared camera night vision effect is not only limited by the infrared light board, chip, etc., but also affected by the mechanism, which needs to attract enough attention.

0 degree, 12 degree wide angle monitor mini camera housing LED light night vision wide angle camera hardware shell

Waterproof miniature coaxial camera housing for fish detector Front and rear camera housing for the car (18.5mm)

PREV:Aluminum Alloy Toolbox

NEXT:NONE

NEXT:NONE