Metal Parts Production Equipment

|

CNC machining center

CNC machining center is a high-efficiency automatic machine tool that is composed of mechanical equipment and numerical control system and is suitable for machining complex parts. CNC machining center is one of the most productive and widely used CNC machine tools in the world. CNC machining center is a high-efficiency automatic machine tool that is composed of mechanical equipment and numerical control system and is suitable for machining complex parts. CNC machining center is one of the most productive and widely used CNC machine tools in the world.Its comprehensive processing ability is strong, the workpiece can complete more processing content once it is clamped, and the processing precision is higher. For batch workpieces with medium processing difficulty, the efficiency is 5 to 10 times that of ordinary equipment. In particular, it can complete the processing that many common equipment can not complete. It is more suitable for single-piece processing with relatively complex shapes and high precision, or for multi-variety production with medium and small batch sizes. It combines functions such as milling, boring, drilling, tapping and thread cutting on one device and has a variety of technological means. Machining centers are classified according to the spatial position of the spindle machining: horizontal and vertical machining centers. According to the use of process classification: boring and milling machining center, composite machining center. According to the special classification of functions: Single workbench, Double worktable and multi worktable machining center. Single-axis, double-axis, three-axis, four-axis, five-axis and machining center with interchangeable headstock. |

|

Automatic Lathe

The automatic lathe is a high-performance, high-precision, low-noise, automatic knife-type lathe. It is an automatic processing machine that controls the machining program by the cam. In addition, there are some CNC automatic lathes, pneumatic automatic lathes and walking lathe. The basic core is that after a certain setting and tuning, they can automatically process the same product for a long time. Suitable for processing precision parts such as copper, aluminum, iron, plastics, etc. The automatic lathe is a high-performance, high-precision, low-noise, automatic knife-type lathe. It is an automatic processing machine that controls the machining program by the cam. In addition, there are some CNC automatic lathes, pneumatic automatic lathes and walking lathe. The basic core is that after a certain setting and tuning, they can automatically process the same product for a long time. Suitable for processing precision parts such as copper, aluminum, iron, plastics, etc.Applicable to instruments, watches, automobiles, motorcycles, bicycles, glasses, stationery, hardware and sanitary, electronic parts, connectors, computers, mobile phones, electrical and mechanical, military and other industries batch processing of small parts, especially the more complex parts. Our company's automatic lathes all use Taiwan Name Yang machine. Knife cutters are mainly based on 20 and 15 models. Production and processing of the largest diameter 20MM. walking lathe maximum working diameter 8MM. In the future, the company will further introduce the computer-style walking lathe. |

|

punch

Punch press is a stamping press. In the national production, the stamping process has the advantages of saving material and energy compared with traditional machining, high efficiency, and low technical requirements for operators. Through a variety of mold application processing, products that cannot be achieved by mechanical processing can be made. Therefore its use is more and more extensive. Punch press is a stamping press. In the national production, the stamping process has the advantages of saving material and energy compared with traditional machining, high efficiency, and low technical requirements for operators. Through a variety of mold application processing, products that cannot be achieved by mechanical processing can be made. Therefore its use is more and more extensive.Stamping production is mainly for sheet metal. Through the mould, blanking, punching, forming, deep drawing, dressing, fine blanking, shaping, riveting and extrusion can be made. It is widely used in various fields. For example, we use switch sockets, cups, cupboards, saucers, computer cases, and even missile planes. There are a lot of accessories that can be punched out with a punch press. |

|

Automatic feeding machine

We adopted an automatic feeder (enlarged drawing below) as the main feeding equipment, eliminating the need for artificial feeding and realizing full self-processing in the true sense. We adopted an automatic feeder (enlarged drawing below) as the main feeding equipment, eliminating the need for artificial feeding and realizing full self-processing in the true sense.The stability and cost-effectiveness of the products are correspondingly improved, which will bring more competitiveness to our company. We are using the automatic feeding machine of the Swiss brand LNS (Origin Suzhou). By the way, let's make an advertisement for them. This is the packaging when we enter the factory. We have the company's phone number on the package. Equipped with automatic delivery machines can increase productivity and reduce labor costs. In the past, an operator could look at five machines at the same time, but now he can see 10 or more machines, while also avoiding the feeding interval caused by artificial factors. |

|

Table Lathe

Auxiliary equipment used as a post-processing or secondary process Auxiliary equipment used as a post-processing or secondary processSome complicated work cannot be completed on the automatic lathe at one time, and it needs to be completed manually on this small lathe. |

|

Tooth rubbing machine

Thread Rolling is mainly for some external thread products such as yin and yang screws, knurling shafts, etc. Thread Rolling is mainly for some external thread products such as yin and yang screws, knurling shafts, etc.Click on the image to enlarge the picture, you can see that Tooth rubbing machine is Rolling a carbon steel hexagonal column |

|

Tooth rubbing machine

Ming Yang brand blade sharpening machine, auxiliary equipment, used for lathe tool making. Ming Yang brand blade sharpening machine, auxiliary equipment, used for lathe tool making. |

Our company's engineers are experts in the selection of high-level automatic lathes. At the same time pay attention to the operator's skills training. Our company's engineers are experts in the selection of high-level automatic lathes. At the same time pay attention to the operator's skills training.Every year, we strictly test and maintain our production and testing equipment. The picture shows debugging automatic lathe processing |

Our inspection equipment:

A good product cannot do without strict inspection. A good product cannot do without strict inspection.Each batch of products undergoes three tests at the factory: work detection/tour inspection/finished product inspection |

|

Secondary element optical microscope

Used to measure product chamfer, angle, tiny size, arc, R angle, and observe the appearance of products such as burrs, cracks, knife marks, pits and other defects. Used to measure product chamfer, angle, tiny size, arc, R angle, and observe the appearance of products such as burrs, cracks, knife marks, pits and other defects.Compared to the projector below, the optical microscope observes the product image itself instead of projection, so it is more intuitive. It can also be observed directly without a computer. Mainly used to measure micro-small products, such as hot-melt nuts |

|

Caliper, micrometer:

Our calipers and micrometers use MITUTOYO precision instruments. On the one hand, they are accurate for measurement. On the other hand, the MITUTOYO calipers are better for oil resistance. As with the above picture, we cannot avoid a lot of oil on our production line. Our calipers and micrometers use MITUTOYO precision instruments. On the one hand, they are accurate for measurement. On the other hand, the MITUTOYO calipers are better for oil resistance. As with the above picture, we cannot avoid a lot of oil on our production line. |

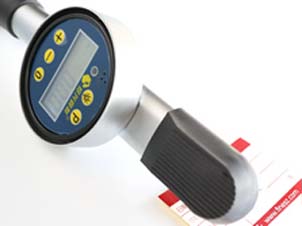

Torque wrench Torque wrenchMeasuring torque. |

|

projector

In order to ensure product quality and minor details, our company imports (SInstrument letter) quadratic element, three-D measuring instrument. Ensure R angle, solitary angle, chamfer, groove depth, parallelism, coaxiality, verticality and surface roughness. In order to ensure product quality and minor details, our company imports (SInstrument letter) quadratic element, three-D measuring instrument. Ensure R angle, solitary angle, chamfer, groove depth, parallelism, coaxiality, verticality and surface roughness. |

|

Salt fog tester

It is mainly used to detect the rust resistance of the product after electroplating It is mainly used to detect the rust resistance of the product after electroplating |