Manufacturing Technology of Intelligent Frequency Conversion Electromagnetic Heating Oil Storage Tank

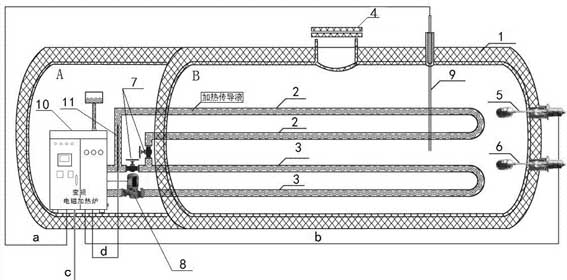

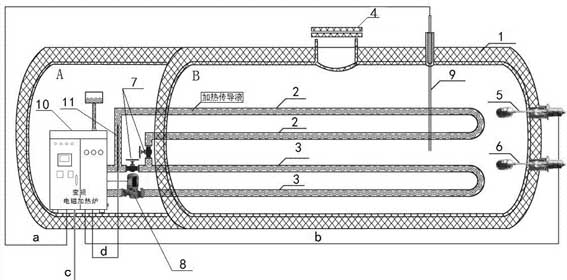

The patented technology of the utility model relates to an intelligent variable frequency electromagnetic heating oil storage tank, which comprises a tank body. The irrigation body is provided with at least one upper transmission liquid coil and one lower transmission liquid coil. At least one upper conductive liquid coil and one lower conductive liquid coil are disposed in the filling body. One end of the upper transfer liquid coil and the lower transfer liquid coil pass through the side of the pothole and are fixed by the side wall of the potter. The filling body is further provided with a first liquid level controller, a second liquid level controller and an oil temperature sensor. A high pressure valve is disposed between the upper transfer liquid coil and the lower transfer liquid coil, and a circulation pump is disposed on the lower transfer liquid coil. The upper transmission liquid coil and the lower transmission liquid coil are connected to an intelligent variable frequency electromagnetic heating furnace. The patented technology of the utility model has a simple and reasonable structure, and can realize the safety and reliability of the layered double temperature double control heating, and the heating and energy saving effect is good.

[Summary of technical implementation steps]

Intelligent variable frequency electromagnetic heating oil storage tank

The technology relates to an oil storage tank, in particular to an intelligent variable frequency electromagnetic heating oil storage tank.

Technology Introduction

In the northern part of China, most oil fields use single-well crude oil storage tanks.

Due to the weather, the temperature of the crude oil drops rapidly after entering the storage tank. As the temperature decreases, the viscosity of the crude oil increases, and the crude oil condenses, which brings great difficulties to the transportation and transportation of crude oil; In addition, the high-viscosity crude oil produced by some oil wells needs to be stored and heated in the well tank before being loaded. In order to solve the above problems, the original heating method has two kinds, one is to use coal burning crude oil method, and the other is to use electric heating heat conduction oil heating method. There are many shortcomings and deficiencies in the above two methods, which are manifested in:

First, the method of burning coal and burning crude oil is the most wasteful energy and a common heating method. The labor intensity of workers is high, the expenses incurred are large, the environment is polluted, the energy consumption is too large, and the maintenance costs are high.

Second, the electric heating heat transfer oil this heating method to a certain extent solves the problem of the waste of every 100 wells in the crude oil heating method, and solves the problem of high labor intensity of workers. The problem of large cost of burning coal-fired crude oil is solved, and automatic control heating is realized.

However, this heating method has the problems of polluting the environment, excessive energy consumption, and high maintenance costs. The far-infrared radiant heating device of the oil storage tank with the patent number 201020220522.X solves the problems of the prior art mentioned above to some extent. However, there are still certain shortcomings and deficiencies, which are manifested in:

1. Since the crude oil extracted from the well is mixed with a certain amount of water, it will form stratification after entering the oil storage tank, the upper layer is crude oil and the lower layer is water. The original structure only heats the mixture of crude oil and water at the same time, and can not achieve stratified heating with seasonal changes, resulting in repeated heating and waste of electric energy.

2. It is impossible to realize segmented intelligent heating control based on liquid level, so that the intelligent temperature control of the oil storage tank cannot be

[Technical Protection Point]

An intelligent variable frequency electromagnetic heating oil storage tank, characterized in that:

The oil storage tank includes a filling body, At least one upper conductive liquid coil is disposed in the middle portion of the filling body, and at least one lower conductive liquid circulating coil is disposed near the bottom of the filling body. One end of the upper conductive liquid coil and the lower conductive liquid coil pass through the side of the pot and are fixed by the side wall of the pot. a corresponding liquid level controller is disposed at a corresponding portion of the conductive liquid coil on the side of the filling body, and a second liquid level control is disposed between the conductive liquid coil and the lower conductive liquid coil on the side of the filling body Device. A high pressure valve is disposed between the upper conductive liquid coil and the lower conductive liquid coil, and a circulation pump is disposed on the lower conductive liquid coil. An oil temperature sensor is also disposed on a side of the upper oil inlet of the filling body. The upper conductive liquid coil and the lower conductive liquid coil are connected to an intelligent variable frequency electromagnetic heating furnace. An end of the upper conductive fluid coil is provided with a furnace temperature sensor.

[Summary of technical implementation steps]

Intelligent variable frequency electromagnetic heating oil storage tank

The technology relates to an oil storage tank, in particular to an intelligent variable frequency electromagnetic heating oil storage tank.

Technology Introduction

In the northern part of China, most oil fields use single-well crude oil storage tanks.

Due to the weather, the temperature of the crude oil drops rapidly after entering the storage tank. As the temperature decreases, the viscosity of the crude oil increases, and the crude oil condenses, which brings great difficulties to the transportation and transportation of crude oil; In addition, the high-viscosity crude oil produced by some oil wells needs to be stored and heated in the well tank before being loaded. In order to solve the above problems, the original heating method has two kinds, one is to use coal burning crude oil method, and the other is to use electric heating heat conduction oil heating method. There are many shortcomings and deficiencies in the above two methods, which are manifested in:

First, the method of burning coal and burning crude oil is the most wasteful energy and a common heating method. The labor intensity of workers is high, the expenses incurred are large, the environment is polluted, the energy consumption is too large, and the maintenance costs are high.

Second, the electric heating heat transfer oil this heating method to a certain extent solves the problem of the waste of every 100 wells in the crude oil heating method, and solves the problem of high labor intensity of workers. The problem of large cost of burning coal-fired crude oil is solved, and automatic control heating is realized.

However, this heating method has the problems of polluting the environment, excessive energy consumption, and high maintenance costs. The far-infrared radiant heating device of the oil storage tank with the patent number 201020220522.X solves the problems of the prior art mentioned above to some extent. However, there are still certain shortcomings and deficiencies, which are manifested in:

1. Since the crude oil extracted from the well is mixed with a certain amount of water, it will form stratification after entering the oil storage tank, the upper layer is crude oil and the lower layer is water. The original structure only heats the mixture of crude oil and water at the same time, and can not achieve stratified heating with seasonal changes, resulting in repeated heating and waste of electric energy.

2. It is impossible to realize segmented intelligent heating control based on liquid level, so that the intelligent temperature control of the oil storage tank cannot be

[Technical Protection Point]

An intelligent variable frequency electromagnetic heating oil storage tank, characterized in that:

The oil storage tank includes a filling body, At least one upper conductive liquid coil is disposed in the middle portion of the filling body, and at least one lower conductive liquid circulating coil is disposed near the bottom of the filling body. One end of the upper conductive liquid coil and the lower conductive liquid coil pass through the side of the pot and are fixed by the side wall of the pot. a corresponding liquid level controller is disposed at a corresponding portion of the conductive liquid coil on the side of the filling body, and a second liquid level control is disposed between the conductive liquid coil and the lower conductive liquid coil on the side of the filling body Device. A high pressure valve is disposed between the upper conductive liquid coil and the lower conductive liquid coil, and a circulation pump is disposed on the lower conductive liquid coil. An oil temperature sensor is also disposed on a side of the upper oil inlet of the filling body. The upper conductive liquid coil and the lower conductive liquid coil are connected to an intelligent variable frequency electromagnetic heating furnace. An end of the upper conductive fluid coil is provided with a furnace temperature sensor.