China Rapid Prototyping Center

- PRODUCT DETAIL

Usually the newly developed or designed products need to be prototyped. Prototyping is the first step in verifying the feasibility of a product. It is the most direct and effective way to find out the defects, deficiencies, and disadvantages of a designed product. In this way, defects can be improved in a targeted manner until deficiencies cannot be identified from individual prototypes. At this point, usually a small amount of trial production is needed to find out the shortcomings in the batch to improve. Designed products are generally not perfect, or even unusable. Direct production will be scrapped once there are defects, greatly wasting manpower, material resources and time; The prototype is generally a small number of samples, the production cycle is short, the loss of manpower and material resources is small, and the shortcomings of product design are quickly found to improve and provide sufficient basis for product stereotypes and mass production.

Classification of rapid prototypes

Classification by means of productionPrototypes can be divided into manual prototypes and CNC prototypes according to the means of production:

(1) Manual prototype: The main workload is done by hand.

(2) CNC prototype: its main workload is completed with CNC machine tools. According to the different equipment used, it can be divided into laser rapid prototyping (RP, Rapid Prototyping) prototype and machining center (CNC) prototype.

A: SLA prototype: mainly a prototype produced by laser rapid prototyping technology.

B: CNC prototype: Mainly a prototype produced by a machining center.

Compared with the CNC prototype, the RP prototype has its own advantages:

The advantages of the RP prototype are mainly reflected in its rapidity, but it is mainly formed by stacking technology, so the RP prototype is generally relatively rough, and has certain requirements for the wall thickness of the product. For example, if the wall thickness is too thin, it cannot be produced.

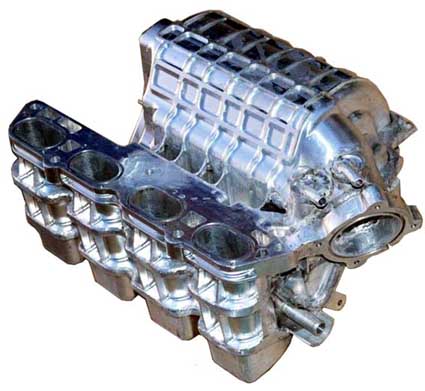

The advantages of the CNC prototype are that it can accurately reflect the information expressed in the drawings, and the surface quality of the CNC prototype is high, especially after the surface spraying and screen printing are completed, even more precise than the products produced after the mold is opened. Therefore, CNC prototype manufacturing is becoming more and more mainstream in prototype manufacturing.

Rapid prototypes are classified by the materials used

Prototypes can be divided into plastic prototypes, silicone prototypes, metal prototypes, and sludge prototypes according to the materials used in production:

(1) Plastic prototype: Its raw material is plastic, which is mainly the prototype of some plastic products, such as televisions, monitors, telephones, etc.

(2) Silicone prototype: Its raw material is silicone, which is mainly used to show the prototype of product design, such as cars, mobile phones, toys, crafts, daily necessities and so on.

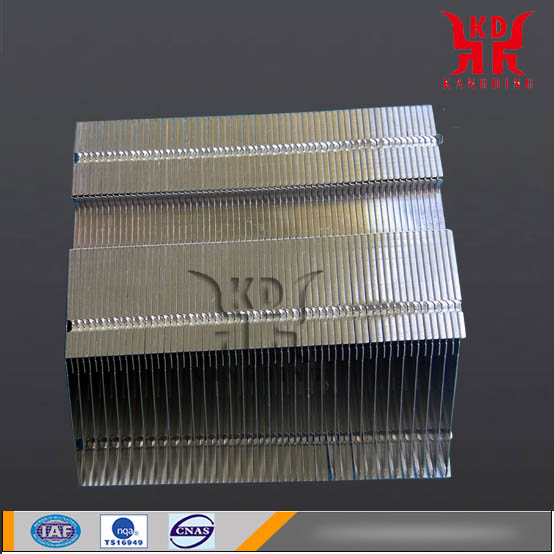

(3) Metal prototype: The raw material is aluminum-magnesium alloy and other metal materials, mainly the prototype of some high-end products, such as notebook computers, advanced single player, MP3 player, CD player and so on.

(4) Prototype of oil sludge:

The raw material is oil sludge, commonly known as mud sculpture prototype, which is mainly used for product design and development. In the early stage of product development, the master of clay sculpture used oil sludge as a model according to his imagination or pictures, and then determined the appearance based on the oil sludge model. However, the current sludge prototype has been replaced by freeform a lot.

C) By prototype level

According to the effect to be achieved, it can be divided into appearance prototype, structural prototype and functional prototype:

(1) Appearance prototype: Mainly inspect the appearance design of the product, which requires beautiful appearance, accurate color, and low requirements for internal treatment.

(2) Structural prototype: The structure of the main test products is reasonable, and the requirements for size are relatively high, and the requirements for appearance are relatively low. Foreign countries are particularly strict with such requirements.

(3) Functional prototype: It is required to achieve the same appearance, structure and function as the real product. It can be understood that the unfinished product is the most demanding and the most difficult type of prototype.

Rapid prototypes are classified by the materials used

Prototypes can be divided into plastic prototypes, silicone prototypes, metal prototypes, and sludge prototypes according to the materials used in production:

(1) Plastic prototype: Its raw material is plastic, which is mainly the prototype of some plastic products, such as televisions, monitors, telephones, etc.

(2) Silicone prototype: Its raw material is silicone, which is mainly used to show the prototype of product design, such as cars, mobile phones, toys, crafts, daily necessities and so on.

(3) Metal prototype: The raw material is aluminum-magnesium alloy and other metal materials, mainly the prototype of some high-end products, such as notebook computers, advanced single player, MP3 player, CD player and so on.

(4) Prototype of oil sludge:

The raw material is oil sludge, commonly known as mud sculpture prototype, which is mainly used for product design and development. In the early stage of product development, the master of clay sculpture used oil sludge as a model according to his imagination or pictures, and then determined the appearance based on the oil sludge model. However, the current sludge prototype has been replaced by freeform a lot.

C) By prototype level

According to the effect to be achieved, it can be divided into appearance prototype, structural prototype and functional prototype:

(1) Appearance prototype: Mainly inspect the appearance design of the product, which requires beautiful appearance, accurate color, and low requirements for internal treatment.

(2) Structural prototype: The structure of the main test products is reasonable, and the requirements for size are relatively high, and the requirements for appearance are relatively low. Foreign countries are particularly strict with such requirements.

(3) Functional prototype: It is required to achieve the same appearance, structure and function as the real product. It can be understood that the unfinished product is the most demanding and the most difficult type of prototype.

Prototyping process

Prototyping methods include hand-made prototypes and CNC prototypes. In the early days, there was no corresponding equipment, and the numerical control technology was backward. Prototyping was mainly done by hand, and the materials and processes had great limitations. There are very few pure hand prototypes. The NC prototype has high precision and high degree of automation, and the resulting prototype can reflect the effect of mass production of products. The later stage is supplemented by manual grinding and other processes of details, so most of the current prototype production is by CNC machining.

PREV:Electric Scooter, Bicycle Accessories CNC Machining

NEXT:NONE

NEXT:NONE