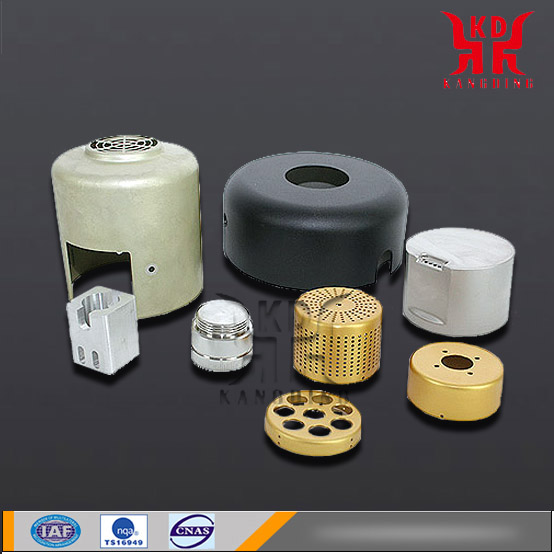

Aluminum fishing tackle assembly CNC machining

- PRODUCT DETAIL

The machining of CNC fishing tackle components adopts aluminum alloy as raw material. After accurate calculation of advanced CNC processing equipment systems, the CNC can customize the processed products from fishing tackle components to the micro-millimeter unit.

Kangding has advanced CNC processing equipment, can produce non-standard precision parts NC processing, processing of various aluminum alloy products in accordance with customer requirements.

In particular, in the custom processing of CNC fishing tackle components, the company has a professional technical production team and advanced production and processing equipment, and promises to deliver high-precision, high-quality products on time.

Name: Fishing tackle assembly

Application: Various fishing tackles, fishing rods

Product material: aluminum alloy

Product process: CNC machining, sandblasting 120# emery, oxidized gray

Product use: fishing gear, fishing rod

Suppliers & Manufacturers

Graph customization

Processing accuracy: 0.005mm

Processing cycle: 7-14 days

Proofing cycle: 1-5 days

Surface roughness: according to customer needs

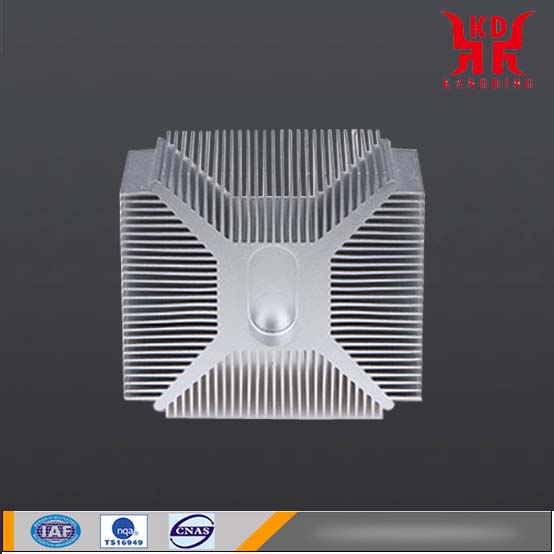

Kangding has advanced CNC processing equipment, can produce non-standard precision parts NC processing, processing of various aluminum alloy products in accordance with customer requirements.

In particular, in the custom processing of CNC fishing tackle components, the company has a professional technical production team and advanced production and processing equipment, and promises to deliver high-precision, high-quality products on time.

Name: Fishing tackle assembly

Application: Various fishing tackles, fishing rods

Product material: aluminum alloy

Product process: CNC machining, sandblasting 120# emery, oxidized gray

Product use: fishing gear, fishing rod

Suppliers & Manufacturers

Graph customization

Processing accuracy: 0.005mm

Processing cycle: 7-14 days

Proofing cycle: 1-5 days

Surface roughness: according to customer needs