China is the center of frozen processing of aquatic products in the world. As the world’s largest exporter of aquatic products, China’s aquatic products require more efficient and energy-saving technology updates.

At present, the freezer boxes on the market are made of plastic, stainless steel materials, and galvanized iron plating. The freezer boxes made of stainless steel and plastic materials have poor thermal conductivity, and have large energy consumption and low thermal efficiency during use.

In the case of low-temperature freezing, the freezing of aquatic products creates tremendous pressure and often causes the plastic freeze-box to burst; The stainless steel freeze box uses stainless steel with a thickness of 0.8-1.0 mm in use, which is very thin. In use, pits are likely to occur, and the difficulty of removing the ice is increased. It is necessary to remove the ice after washing in hot water. However, in the process of rinsing with hot water, the ice cubes melt and do not reach the required weight, so the operation is very difficult.

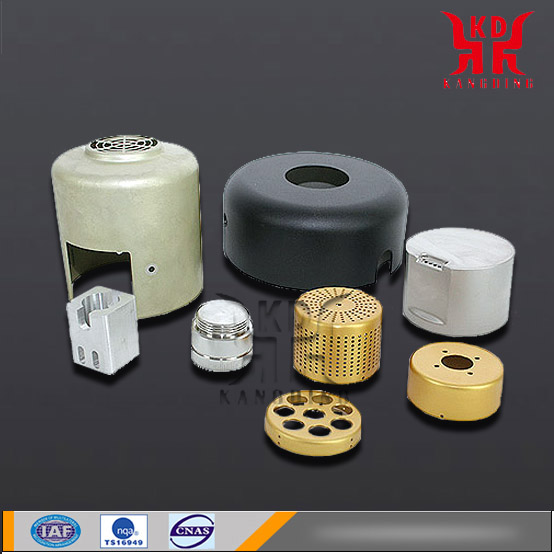

The purpose of the present invention is to overcome the shortcomings of the prior art and provide a new type of aluminum freeze box which is made by stretching an entire aluminum plate and consists of a lower container and a box cover. An oxidizing solution is applied to the box body and the lid, and a projection is provided around the lid of the lid. There are six holes in the plane of the lid to increase the contact with the outside world, so that the temperature drops rapidly, and when it needs to be closed, it is closed with the lid; When not closed, the lower container can be used alone.

Its advantages are: due to the use of aluminum plate tensile production, so that the frozen box is not easy to break, the internal is not easy to appear protruding, Make demoulding easy, freezing time is about 20 minutes faster than other freezers, which can increase work efficiency more. Moreover, this product has a very high environmental performance. Waste aluminum alloy freezers can be recycled and reused, and they can be recycled to make other products.

Stretching, manual freezing box specifications can be customized according to customer needs.

The application of the freezer box: The independently developed aluminum alloy freezer box is made of high-quality aluminum sheet and aluminum sheet. It has the advantages of long service life, good heat transfer effect, and high demoulding speed. The Asian seafood (Zhanjiang) company, Maoming Xinzhou company, Beihai Hongtai company, etc. have all gained good reputation.This product is widely used in frozen processing industries such as aquatic products, seafood, meat products, agricultural and sideline products, and frozen foods.

At present, the freezer boxes on the market are made of plastic, stainless steel materials, and galvanized iron plating. The freezer boxes made of stainless steel and plastic materials have poor thermal conductivity, and have large energy consumption and low thermal efficiency during use.

In the case of low-temperature freezing, the freezing of aquatic products creates tremendous pressure and often causes the plastic freeze-box to burst; The stainless steel freeze box uses stainless steel with a thickness of 0.8-1.0 mm in use, which is very thin. In use, pits are likely to occur, and the difficulty of removing the ice is increased. It is necessary to remove the ice after washing in hot water. However, in the process of rinsing with hot water, the ice cubes melt and do not reach the required weight, so the operation is very difficult.

The purpose of the present invention is to overcome the shortcomings of the prior art and provide a new type of aluminum freeze box which is made by stretching an entire aluminum plate and consists of a lower container and a box cover. An oxidizing solution is applied to the box body and the lid, and a projection is provided around the lid of the lid. There are six holes in the plane of the lid to increase the contact with the outside world, so that the temperature drops rapidly, and when it needs to be closed, it is closed with the lid; When not closed, the lower container can be used alone.

Its advantages are: due to the use of aluminum plate tensile production, so that the frozen box is not easy to break, the internal is not easy to appear protruding, Make demoulding easy, freezing time is about 20 minutes faster than other freezers, which can increase work efficiency more. Moreover, this product has a very high environmental performance. Waste aluminum alloy freezers can be recycled and reused, and they can be recycled to make other products.

Stretching, manual freezing box specifications can be customized according to customer needs.

The application of the freezer box: The independently developed aluminum alloy freezer box is made of high-quality aluminum sheet and aluminum sheet. It has the advantages of long service life, good heat transfer effect, and high demoulding speed. The Asian seafood (Zhanjiang) company, Maoming Xinzhou company, Beihai Hongtai company, etc. have all gained good reputation.This product is widely used in frozen processing industries such as aquatic products, seafood, meat products, agricultural and sideline products, and frozen foods.