16 Kinds Of Metal Stamping Drawing Processing Methods,Aluminum products,Stainless steel processing

The use of stamping equipment for the product's drawing forming process, Including: Stretch machining, Reverse drawing, Redrawing and ironing machining.

Stretch machining: Using a pressure plate device, using punch pressure, The flat plate material part or all of the pull-in recess-mold, so shaped as a container with a bottom. The side wall of the container is parallel to the drawing direction, It is a simple stretch processing. The stretching processing of cone (or pyramid)-shaped containers, hemispherical containers, parabolic surface containers, etc. also includes expansion processing.

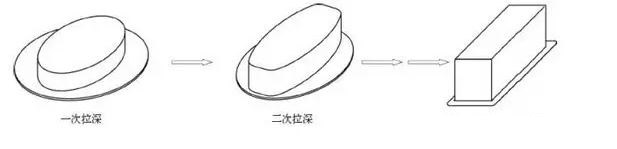

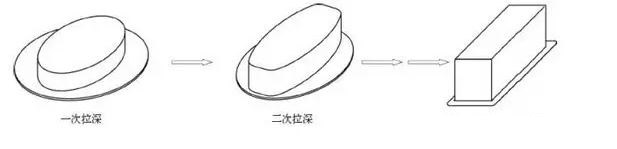

Redrawing: deep drawing products that cannot be completed by one-step drawing process. The shaped product needs to be re-stretched, To increase the depth of the forming container.

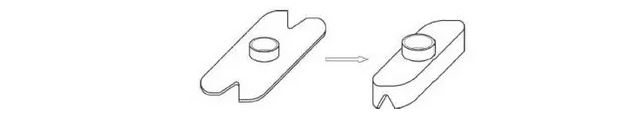

Reverse drawing: The workpiece is stretched first and then Reverse drawing, The inside of the workpiece becomes the outer side and the outer diameter becomes smaller.

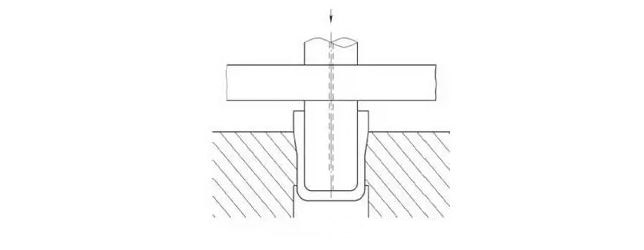

ironing machining: Using a punch to squeeze the formed container into a concave cavity slightly smaller than the outside diameter of the container, so that the outside diameter of the bottomed container becomes smaller, at the same time, the thinning of the wall thickness eliminates the deviation of the wall thickness and makes the surface of the container smooth.

The following 16 types are included in Stretch processing using a stamping device:

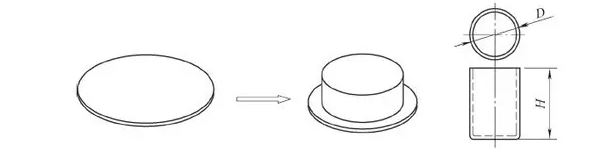

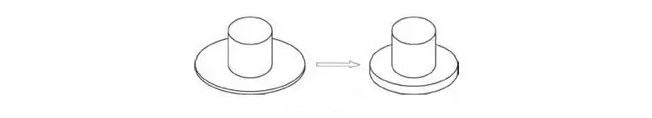

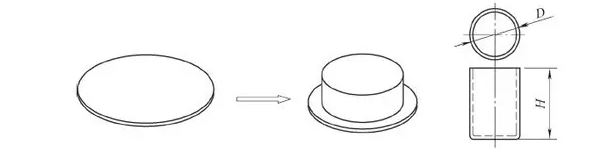

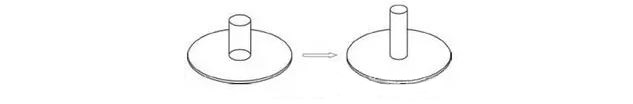

1, Round drawing:

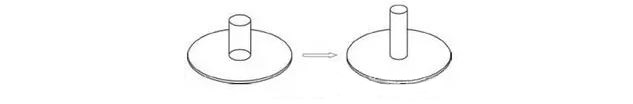

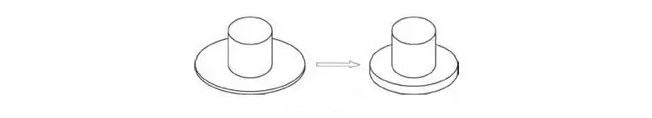

Stretching of flanged cylindrical products. The flange and the bottom are both in a plane shape. The cylindrical sidewall is axisymmetric. The deformation is evenly distributed on the same circumference, and the blank on the flange is deep-drawn and deformed.

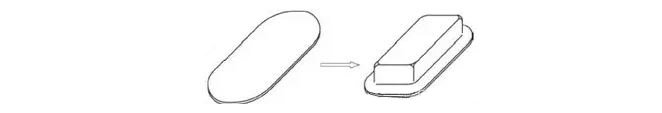

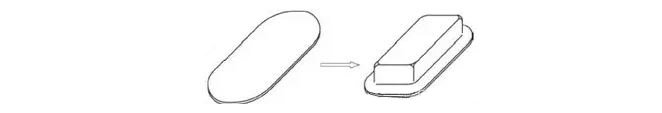

2, Ellipse drawing: The deformation of the blank on the flange is tensile deformation, but the deformation amount and deformation ratio change correspondingly along the contour shape. The greater the curvature, the greater the plastic deformation of the blank. Conversely, the smaller the curvature, the smaller the plastic deformation of the blank.

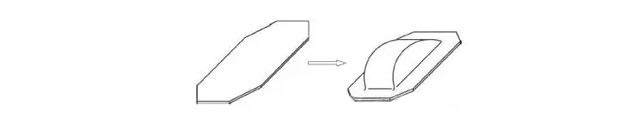

3, Rectangular drawing: One-step stretch forming, low rectangular pieces. When stretched, the stretch resistance at the corner of the flange deformation zone is greater than the stretch resistance at the straight edge, and the deformation at the rounded corner is greater than the deformation at the straight edge.

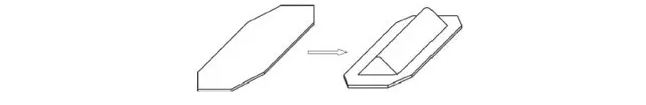

4, Hill drawing: When the side wall of the stamped part is inclined, the side wall is vacant during the stamping process and is not die-attached. The mold is not attached until the end of the forming. The deformation characteristics of the different parts of the sidewalls are not exactly the same.

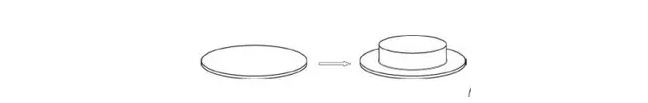

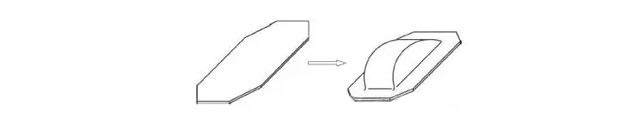

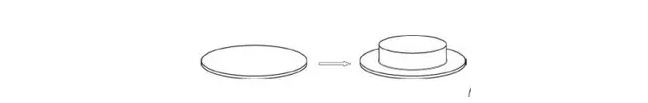

5. Hill drawing: The deformation of the blank in the forming process of the dome-shaped lid member is not a simple tensile deformation, but a combined forming in which stretching and bulging deformation simultaneously exist. The deformation of the blank on the pressing surface is tensile deformation (tensile stress in the radial direction and compressive stress in the tangential direction), while the deformation of the blank inside the contour (especially in the central area) is bulging deformation (both radial and tangential For tensile stress).

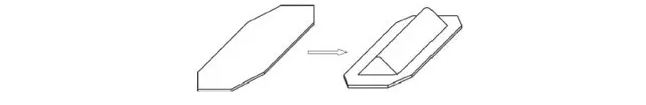

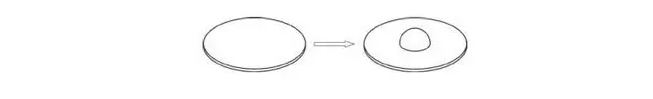

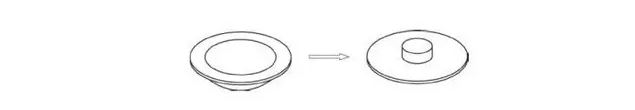

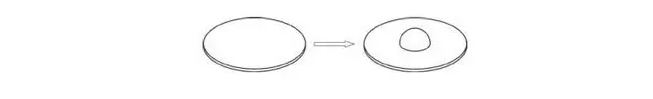

6, With flange hemisphere drawing: When the ball is stretched, the blank is in partial contact with the spherical top of the punch, and most of the rest is in a free, unconstrained, free state. Therefore, the main process problems of such spherical parts are: It is due to the severe thinning of the local contact portion or the wrinkling of the curved surface portion.

8, Flange drawing: For the flanges of the pre-stretched product, perform angular re-stretching. This kind of processing requires the material to have good plasticity.

9, deep drawing: Extruded products that exceed the limit of the stretching process must be completed after two or more stretchings. After the first stretching station in the depth direction of the product, re-stretching in the depth direction. Wide flange extensions, stretched to the required flange diameter when stretched the previous time. When it is stretched again, the flange diameter remains unchanged.

12, Surface forming: Curved surface forming, The outer flange portion of the metal flat blank is reduced and the inner flange portion is elongated. A stamping method for a hollow-shaped product with a non-straight wall/non-flat bottom.

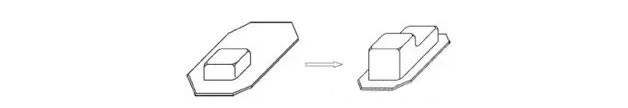

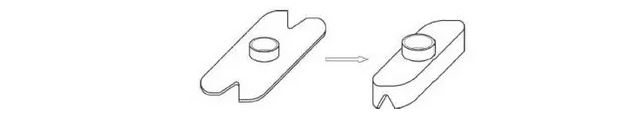

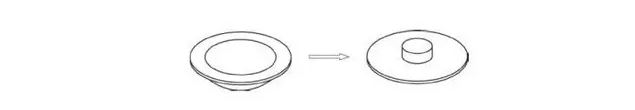

13, Step drawing: The left initial stretched product is re-stretched to form a stepped bottom on the right side. The deeper portion is deformed at the initial stage of stretch forming, and the shallower portion is deformed at the later stage of stretching. The side wall of the stepped portion is susceptible to deformation induced by shear stress.

14, Reverse drawing: The workpiece that is stretched in the previous process is reverse-stretched and is a type of re-stretching. The reverse stretching method can increase the radial tensile stress and can receive better results in preventing wrinkling. It is also possible to improve the tensile coefficients are stretched.

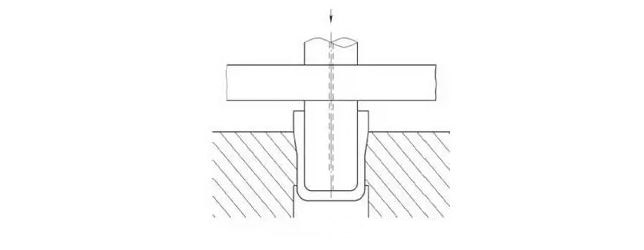

15, ironing: Different from ordinary stretching, Ironing mainly changes the thickness of the wall of the stretching part during stretching. The gap between convex and concave dies is less than the thickness of the blank. The straight wall part of the blank is under a large uniform compressive stress when passing through the gap, and the wall thickness is thinned during the stretching process. Eliminate container wall thickness deviation, increase the smoothness of the container surface, improve accuracy and strength.

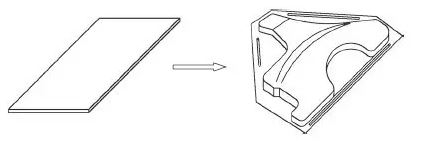

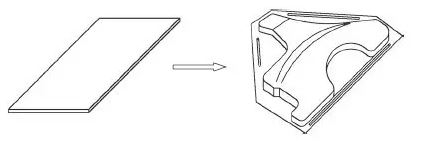

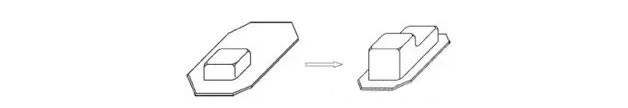

16, Panel drawing: Panel products are sheet stampings with complex surface shapes. In the stretching process, the blank is deformed in a complicated manner, and its forming property is not a simple stretching forming but a composite forming in which drawing and bulging simultaneously exist.

Stretch machining: Using a pressure plate device, using punch pressure, The flat plate material part or all of the pull-in recess-mold, so shaped as a container with a bottom. The side wall of the container is parallel to the drawing direction, It is a simple stretch processing. The stretching processing of cone (or pyramid)-shaped containers, hemispherical containers, parabolic surface containers, etc. also includes expansion processing.

Redrawing: deep drawing products that cannot be completed by one-step drawing process. The shaped product needs to be re-stretched, To increase the depth of the forming container.

Reverse drawing: The workpiece is stretched first and then Reverse drawing, The inside of the workpiece becomes the outer side and the outer diameter becomes smaller.

ironing machining: Using a punch to squeeze the formed container into a concave cavity slightly smaller than the outside diameter of the container, so that the outside diameter of the bottomed container becomes smaller, at the same time, the thinning of the wall thickness eliminates the deviation of the wall thickness and makes the surface of the container smooth.

The following 16 types are included in Stretch processing using a stamping device:

1, Round drawing:

Stretching of flanged cylindrical products. The flange and the bottom are both in a plane shape. The cylindrical sidewall is axisymmetric. The deformation is evenly distributed on the same circumference, and the blank on the flange is deep-drawn and deformed.

2, Ellipse drawing: The deformation of the blank on the flange is tensile deformation, but the deformation amount and deformation ratio change correspondingly along the contour shape. The greater the curvature, the greater the plastic deformation of the blank. Conversely, the smaller the curvature, the smaller the plastic deformation of the blank.

3, Rectangular drawing: One-step stretch forming, low rectangular pieces. When stretched, the stretch resistance at the corner of the flange deformation zone is greater than the stretch resistance at the straight edge, and the deformation at the rounded corner is greater than the deformation at the straight edge.

4, Hill drawing: When the side wall of the stamped part is inclined, the side wall is vacant during the stamping process and is not die-attached. The mold is not attached until the end of the forming. The deformation characteristics of the different parts of the sidewalls are not exactly the same.

6, With flange hemisphere drawing: When the ball is stretched, the blank is in partial contact with the spherical top of the punch, and most of the rest is in a free, unconstrained, free state. Therefore, the main process problems of such spherical parts are: It is due to the severe thinning of the local contact portion or the wrinkling of the curved surface portion.

7, Flange drawing: The stretched product of the flange portion, the shallow drawing process. Its stress and strain conditions are similar to those of compression flanges. Due to tangential compressive stress, wrinkles are likely to occur, so the forming limit is mainly limited by the compression wrinkles.

8, Flange drawing: For the flanges of the pre-stretched product, perform angular re-stretching. This kind of processing requires the material to have good plasticity.

9, deep drawing: Extruded products that exceed the limit of the stretching process must be completed after two or more stretchings. After the first stretching station in the depth direction of the product, re-stretching in the depth direction. Wide flange extensions, stretched to the required flange diameter when stretched the previous time. When it is stretched again, the flange diameter remains unchanged.

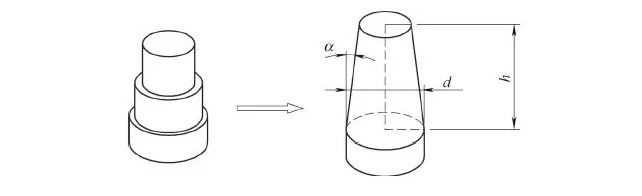

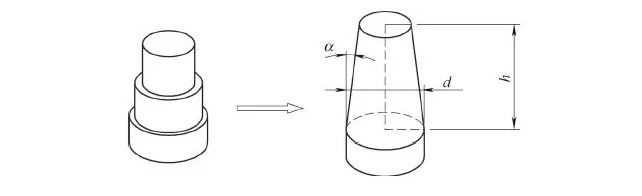

10,Taper drawin: For deep cones with h/d>0.8 and α =10° to 30°, the deformation of the blank is greater due to the greater depth. Reliance on the local area of the billet in contact with the punch to transfer the forming force can easily cause local over-thinning and cracking of the billet, which requires multiple transitions to gradually form. The step stretching method is to first stretch the blank into a step transition piece, Its stepped shape is tangent to the inner shape of the tapered part and bulges later to form a taper. The number of stretching steps, processes, etc. of the step transition piece are the same as those of the step cylindrical piece.

11, Rectangular redrawing: Multiple stretch forming, high rectangular pieces, the deformation is not only different from the stretching of the deep cylindrical member but also very different from the deformation of the low box member. Multi-station automatic presses for high rectangular box processing In the multiple drawing process, the shape and size of the part change with the height of the stretching.

12, Surface forming: Curved surface forming, The outer flange portion of the metal flat blank is reduced and the inner flange portion is elongated. A stamping method for a hollow-shaped product with a non-straight wall/non-flat bottom.

13, Step drawing: The left initial stretched product is re-stretched to form a stepped bottom on the right side. The deeper portion is deformed at the initial stage of stretch forming, and the shallower portion is deformed at the later stage of stretching. The side wall of the stepped portion is susceptible to deformation induced by shear stress.

14, Reverse drawing: The workpiece that is stretched in the previous process is reverse-stretched and is a type of re-stretching. The reverse stretching method can increase the radial tensile stress and can receive better results in preventing wrinkling. It is also possible to improve the tensile coefficients are stretched.

15, ironing: Different from ordinary stretching, Ironing mainly changes the thickness of the wall of the stretching part during stretching. The gap between convex and concave dies is less than the thickness of the blank. The straight wall part of the blank is under a large uniform compressive stress when passing through the gap, and the wall thickness is thinned during the stretching process. Eliminate container wall thickness deviation, increase the smoothness of the container surface, improve accuracy and strength.

16, Panel drawing: Panel products are sheet stampings with complex surface shapes. In the stretching process, the blank is deformed in a complicated manner, and its forming property is not a simple stretching forming but a composite forming in which drawing and bulging simultaneously exist.