CNC Machining Where is The Way Out?

A few days ago Kangding Engineering (the public number) wrote a "CNC machining cheap orders", which hurt himself, injured his counterparts and pitted customers! After I read it, I feel quite touched, and the industry has developed into the present. It must be desperate to fight than the unit price? There are more than one million CNC machining machines in China. If we can save 5% of the processing time, instead of reducing the unit price by 5%, this will greatly promote the development of the entire industry!

No change in raw materials, process innovation and improvement is not under the premise, CNC machining Where is the way out? Through online research and offline visits, the author finally found an amazing solution – the ultra-fast forging of UniForge!

The traditional CNC processing method is to buy aluminum extrusion material, the entire piece of aluminum extrusion material is clamped down in the fixture processing, this process everyone fight or can save:

1, aluminum extrusion material (can be cheaper? Can small piece points, save some material? Can you use recycled materials? Will there be an appearance problem after anodization? ...)

2, CNC machining time is shortened (optimized machining path? Reduce the number of tools? Feed too fast will the workpiece deformation? Is it too costly to process too fast a tool? Custom made tool? ...)

3, the tool to improve the yield (design to reduce the station process? Folder fixture design improvements? Processing temperature conditions control? Tool life management? ...)

However, the CNC processing industry has reached a bottleneck. The use of materials in the emerging new materials, such as ceramics, liquid metals, stainless steel, etc., but the cost has not declined, processing is not profitable, and even less easy. The emergence of UniForge is a revolutionary innovation and breakthrough in materials and processes!

Compared with the traditional hydraulic forging, the part to be machined is much less, and even the structure of the inner cavity is forged. This is not possible with conventional hydraulic forging. More importantly, the required raw materials are also reduced by 40% to 50%.

The original Unibody full CNC processing required about 8mm, because the need for clamping, length and width is significantly larger than the UniForge, and now use UniForge ultra-high speed forging materials only 4mm! Think again, usually to save just 3%, 5% to be with material suppliers compete for a long time. Using UniForge not only saves raw materials, but also reduces CNC machining time, which has a huge influence on the CNC processing industry.

It is understood that this UniForge ultra-high speed forging method is based on Pindar Technology in Taiwan. The process was not originally developed for use in the electronics industry, so mobile phone manufacturers know very little.

Many people have doubts, SUS316 stainless steel for iPhone X can be forged? can. According to the introduction of Pindar Technology, they have forged stainless steel! Yes, UniForge the original require several "forging + tempering" cumbersome process, Changed to a single process, UniForge can be forging to complete, A project? ! Yes, there is only one project, a set of molds will forge the following semi-finished products. The forging ratio is much better than traditional forging, which not only saves the amount of material used, but also shortens the CNC machining time! The author boldly speculated that if this UniForge can be used to forge a stainless steel frame, the cost should be at least lower than the traditional process.

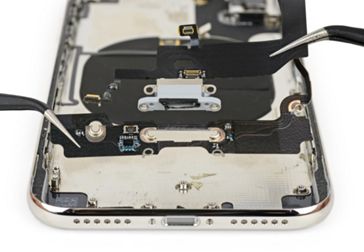

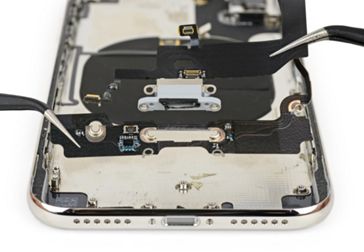

The processing cost of stainless steel is almost 2 times that of aluminum alloy machining because of the large loss of machining tools. Stainless steel has high toughness and a long processing time, so the processing cost has remained high. Therefore, although stainless steel has good structural performance and appearance characteristics, especially the middle frame, it has only been used in high-end models, such as iphone X. Iphone X box is made of SUS 316 stainless steel, then the middle plate is magnesium alloy injection molding, after the completion of these two and then rib combination, it is said that Apple stainless steel frame full processing and magnesium alloy injection plate price over 320RMB ! This has to allow the author to help people get ridiculed, if you can combine stainless steel UniForge + aluminum alloy plate, where is the need to use this price!

Establishing a place in the processing industry is a difficult task. As the market's cost pressures continue to rise, there must be a radical change before it is possible to obtain breathing space and room for growth. As the engineer said, the unit price will hurt himself, pit colleagues, pit customers! The UniForge ultra-fast forging seems to be a good solution.

Establishing a place in the processing industry is a difficult task. As the market's cost pressures continue to rise, there must be a radical change before it is possible to obtain breathing space and room for growth. As the engineer said, the unit price will hurt himself, pit colleagues, pit customers! The UniForge ultra-fast forging seems to be a good solution.

No change in raw materials, process innovation and improvement is not under the premise, CNC machining Where is the way out? Through online research and offline visits, the author finally found an amazing solution – the ultra-fast forging of UniForge!

The traditional CNC processing method is to buy aluminum extrusion material, the entire piece of aluminum extrusion material is clamped down in the fixture processing, this process everyone fight or can save:

1, aluminum extrusion material (can be cheaper? Can small piece points, save some material? Can you use recycled materials? Will there be an appearance problem after anodization? ...)

2, CNC machining time is shortened (optimized machining path? Reduce the number of tools? Feed too fast will the workpiece deformation? Is it too costly to process too fast a tool? Custom made tool? ...)

3, the tool to improve the yield (design to reduce the station process? Folder fixture design improvements? Processing temperature conditions control? Tool life management? ...)

However, the CNC processing industry has reached a bottleneck. The use of materials in the emerging new materials, such as ceramics, liquid metals, stainless steel, etc., but the cost has not declined, processing is not profitable, and even less easy. The emergence of UniForge is a revolutionary innovation and breakthrough in materials and processes!

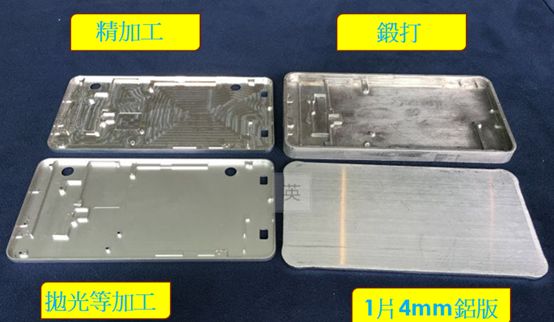

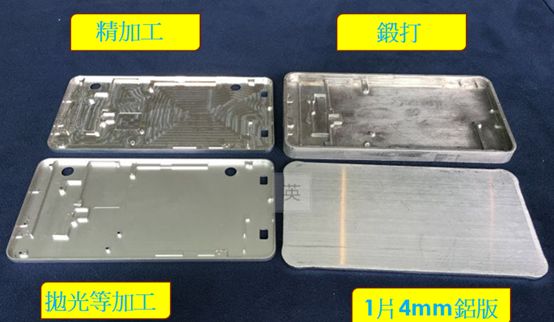

6063 material UniForge forging photo

Compared with the traditional hydraulic forging, the part to be machined is much less, and even the structure of the inner cavity is forged. This is not possible with conventional hydraulic forging. More importantly, the required raw materials are also reduced by 40% to 50%.

The original Unibody full CNC processing required about 8mm, because the need for clamping, length and width is significantly larger than the UniForge, and now use UniForge ultra-high speed forging materials only 4mm! Think again, usually to save just 3%, 5% to be with material suppliers compete for a long time. Using UniForge not only saves raw materials, but also reduces CNC machining time, which has a huge influence on the CNC processing industry.

It is understood that this UniForge ultra-high speed forging method is based on Pindar Technology in Taiwan. The process was not originally developed for use in the electronics industry, so mobile phone manufacturers know very little.

UniForge ultra-high speed forging a sample chart

The picture above is the aluminum alloy UniForge's mobile phone middle frame, seeing this many people will think of later 5G mobile phone use. It will be a mid-frame + double-sided glass structure, but as the thickness becomes thinner and thinner, strength will be a big challenge.Many people have doubts, SUS316 stainless steel for iPhone X can be forged? can. According to the introduction of Pindar Technology, they have forged stainless steel! Yes, UniForge the original require several "forging + tempering" cumbersome process, Changed to a single process, UniForge can be forging to complete, A project? ! Yes, there is only one project, a set of molds will forge the following semi-finished products. The forging ratio is much better than traditional forging, which not only saves the amount of material used, but also shortens the CNC machining time! The author boldly speculated that if this UniForge can be used to forge a stainless steel frame, the cost should be at least lower than the traditional process.

The processing cost of stainless steel is almost 2 times that of aluminum alloy machining because of the large loss of machining tools. Stainless steel has high toughness and a long processing time, so the processing cost has remained high. Therefore, although stainless steel has good structural performance and appearance characteristics, especially the middle frame, it has only been used in high-end models, such as iphone X. Iphone X box is made of SUS 316 stainless steel, then the middle plate is magnesium alloy injection molding, after the completion of these two and then rib combination, it is said that Apple stainless steel frame full processing and magnesium alloy injection plate price over 320RMB ! This has to allow the author to help people get ridiculed, if you can combine stainless steel UniForge + aluminum alloy plate, where is the need to use this price!