Purity

Purity is one of the main performance indicators of titanium targets, because the purity of the titanium target has a great influence on the performance of the film. However, in practical applications, the purity requirements for titanium targets are not the same. For example, with the rapid development of the microelectronics industry, silicon wafer sizes have grown from 6”, 8” to 12”, and the wiring width has been reduced from 0.5um to 0.25um, 0.18um, or even 0.13um. The purity of 99.995% of the titanium target can meet the 0.35umIC process requirements, and the purity of the 0.18um line for the titanium target requires 99.999% or even 99.9999%.

Impurity content

Impurities in the titanium target solids and oxygen and moisture in the pores are the major sources of contamination of the deposited film. Titanium targets with different uses have different requirements for the content of different impurities. For example, pure aluminum and aluminum alloy titanium targets used in the semiconductor industry have special requirements for alkali metal content and radioactive element content.

Density

In order to reduce the porosity in the titanium target solids and improve the performance of the sputtered film, titanium targets are generally required to have a higher density. The density of the titanium target not only affects the sputtering rate, but also affects the electrical and optical properties of the film. The higher the titanium target density, the better the film performance. In addition, increasing the density and strength of the titanium target allows the titanium target to better withstand thermal stresses during the sputtering process. Density is also one of the key performance indicators of titanium targets.

Grain size and grain size distribution

Usually the titanium target is a polycrystalline structure, and the grain size can range from micrometers to millimeters. For the same type of titanium target, the fine-grained target has a higher sputtering rate than the coarse-grained target. For target sputtering with a small difference in grain size (uniform distribution), the thickness distribution of the deposited film is more uniform.

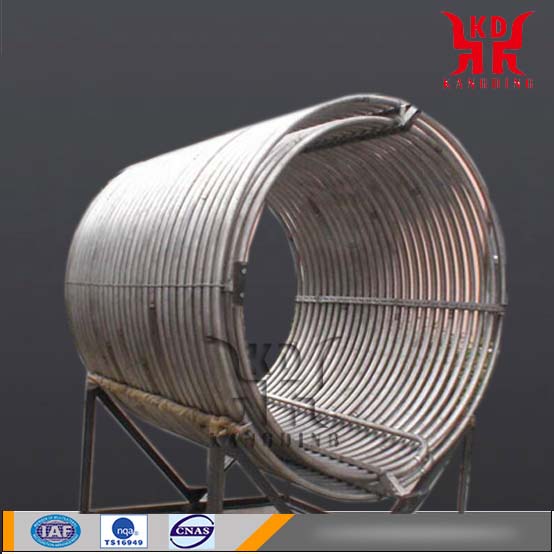

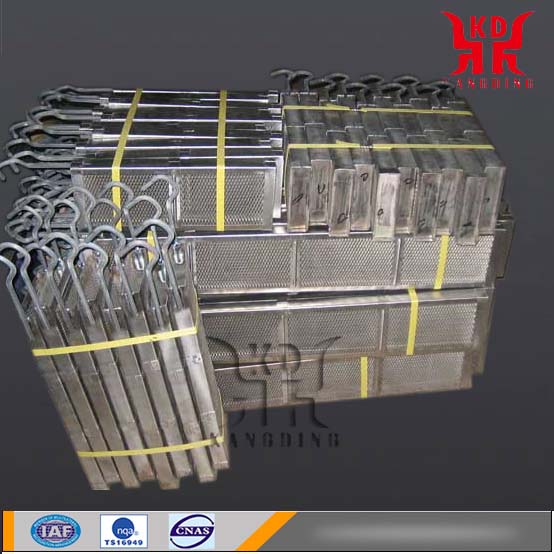

W-Ti target

The dimensions are:

Rectangular target: L800mm×W200mm×H Customer's optional thickness. (Maximum size of similar products in the world)

Round Target: Ф460mm×H Customer's Optional Thickness (Maximum Size of International Similar Products)

Density ≥ 99.9%TD,

Purity ≥ 99.995%

The above three indicators are the highest level of domestic products, the international advanced level

Application

Tungsten-titanium (W-Ti) films and tungsten-titanium (W-Ti)-based alloy films are superalloy films with a series of irreplaceable excellent properties. Tungsten has properties such as high melting point, high strength, and low thermal expansion coefficient. W/Ti alloys have low resistivity, good thermal stability and oxidation resistance. For example, Al, Cu, and Ag have been widely used and researched for various devices that require conductive metal wiring. However, the wiring metal itself is easily oxidized, easily reacts with the surrounding environment, has poor adhesion to the dielectric layer, and easily diffuses into substrate materials such as Si and SiO2. At lower temperatures, compounds of metal and Si are formed, which act as impurities, which greatly degrades device performance. The W-Ti alloy is easily used as a wiring diffusion barrier due to its stable thermo-mechanical properties, low electron mobility, high corrosion resistance, and chemical stability, and is particularly suitable for use in environments with high currents and temperatures.

Prospects

Tungsten-titanium targets have recently been developed as photovoltaic cell coating materials. It is the best choice for third-generation solar cell barriers.

Due to the excellent performance of W-Ti series thin films, the application volume has increased dramatically in recent years. In 2008, the world usage of W-Ti target has reached 400t. With the development of photovoltaic industry, the demand for such targets will increase. The bigger. The industry predicts that there will be a large increase in its usage.The international solar cell market has grown at a rate of 100%. At present, more than 30 companies in the world participate in the further development of the solar energy market, and existing company products are put into the market. The oversized, high-density, high-purity W-Ti target developed by China is a new type of ion sputtering target material. Can be widely used in the display of the barrier layer or toning layer, the decorative layer of notebook computers, battery packaging, solar (photovoltaic) battery barrier, has a very good market prospects and economic benefits. On the other hand, it can also promote the upgrading of tungsten products in China and obtain higher added value.

Purity is one of the main performance indicators of titanium targets, because the purity of the titanium target has a great influence on the performance of the film. However, in practical applications, the purity requirements for titanium targets are not the same. For example, with the rapid development of the microelectronics industry, silicon wafer sizes have grown from 6”, 8” to 12”, and the wiring width has been reduced from 0.5um to 0.25um, 0.18um, or even 0.13um. The purity of 99.995% of the titanium target can meet the 0.35umIC process requirements, and the purity of the 0.18um line for the titanium target requires 99.999% or even 99.9999%.

Impurity content

Impurities in the titanium target solids and oxygen and moisture in the pores are the major sources of contamination of the deposited film. Titanium targets with different uses have different requirements for the content of different impurities. For example, pure aluminum and aluminum alloy titanium targets used in the semiconductor industry have special requirements for alkali metal content and radioactive element content.

Density

In order to reduce the porosity in the titanium target solids and improve the performance of the sputtered film, titanium targets are generally required to have a higher density. The density of the titanium target not only affects the sputtering rate, but also affects the electrical and optical properties of the film. The higher the titanium target density, the better the film performance. In addition, increasing the density and strength of the titanium target allows the titanium target to better withstand thermal stresses during the sputtering process. Density is also one of the key performance indicators of titanium targets.

Grain size and grain size distribution

Usually the titanium target is a polycrystalline structure, and the grain size can range from micrometers to millimeters. For the same type of titanium target, the fine-grained target has a higher sputtering rate than the coarse-grained target. For target sputtering with a small difference in grain size (uniform distribution), the thickness distribution of the deposited film is more uniform.

W-Ti target

The dimensions are:

Rectangular target: L800mm×W200mm×H Customer's optional thickness. (Maximum size of similar products in the world)

Round Target: Ф460mm×H Customer's Optional Thickness (Maximum Size of International Similar Products)

Density ≥ 99.9%TD,

Purity ≥ 99.995%

The above three indicators are the highest level of domestic products, the international advanced level

Application

Tungsten-titanium (W-Ti) films and tungsten-titanium (W-Ti)-based alloy films are superalloy films with a series of irreplaceable excellent properties. Tungsten has properties such as high melting point, high strength, and low thermal expansion coefficient. W/Ti alloys have low resistivity, good thermal stability and oxidation resistance. For example, Al, Cu, and Ag have been widely used and researched for various devices that require conductive metal wiring. However, the wiring metal itself is easily oxidized, easily reacts with the surrounding environment, has poor adhesion to the dielectric layer, and easily diffuses into substrate materials such as Si and SiO2. At lower temperatures, compounds of metal and Si are formed, which act as impurities, which greatly degrades device performance. The W-Ti alloy is easily used as a wiring diffusion barrier due to its stable thermo-mechanical properties, low electron mobility, high corrosion resistance, and chemical stability, and is particularly suitable for use in environments with high currents and temperatures.

Prospects

Tungsten-titanium targets have recently been developed as photovoltaic cell coating materials. It is the best choice for third-generation solar cell barriers.

Due to the excellent performance of W-Ti series thin films, the application volume has increased dramatically in recent years. In 2008, the world usage of W-Ti target has reached 400t. With the development of photovoltaic industry, the demand for such targets will increase. The bigger. The industry predicts that there will be a large increase in its usage.The international solar cell market has grown at a rate of 100%. At present, more than 30 companies in the world participate in the further development of the solar energy market, and existing company products are put into the market. The oversized, high-density, high-purity W-Ti target developed by China is a new type of ion sputtering target material. Can be widely used in the display of the barrier layer or toning layer, the decorative layer of notebook computers, battery packaging, solar (photovoltaic) battery barrier, has a very good market prospects and economic benefits. On the other hand, it can also promote the upgrading of tungsten products in China and obtain higher added value.