Titanium flange is a kind of part made of nonferrous metal titanium or titanium alloy, which is convenient for connecting pipes.

There are holes in the titanium flange, and the bolts tighten the two flanges. The flanges are sealed with a gasket. Flanged pipe fittings are with (flange or socket).

It may be cast from, but also by screwing or welding together. A flange joint consists of a pair of flanges, a washer, and bolts and nuts. The gasket is placed between the sealing surfaces of the two flanges. After the nut is tightened, the specific pressure on the gasket surface is deformed after the specific pressure reaches a certain value, and the unevenness on the sealing surface is filled so that the connection is tightly sealed.

Press the connection part

The titanium flange connection is a detachable connection. According to the connected components can be divided into container titanium flange and pipe titanium flange.

Form of the structure

According to the structural type, there are integral titanium flange, butt welded titanium flange, loose titanium flange and threaded titanium flange.

Titanium flange standard

Titanium flange number:

TA0, TA1, TA2, TA3, TA4, TA5, TA6, TA7, TA9, TA10, TC1, TC2, TC3, TC4, TC6, TC11, Grade1 Grade2 Grade5 Grade7 Grade9 Grade12Ti6AL4V ELI, Ti6AL7Nb, Ti13Nb13Zr, Ti1533.

Titanium Flange Availability: R or M

Titanium flange specifications: titanium plate 0.03-20mm*1000mm*2000mm

Titanium foil, titanium band thickness 0.01 to 0.1mm.

Width 120mm. Spot 0.03mm to 0.8mm Width from 80 to 500mm

Titanium rod (light rod) 2mm-250mm*3000mm

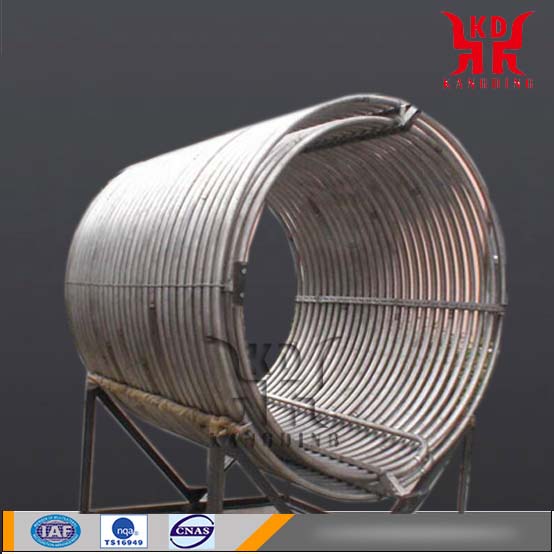

Titanium tube diameter 3 to 120mm

Wall thickness from 0.5 to 20mm.4-110mm*0.8-10mm*6000mm

Titanium wire 0.1-8.0mm

Titanium cake 50mm-500mm*50mm-1000mm

Titanium ring diameter 100 to 2020mm

Wall thickness from 10 to 300mm

Executive standard:

GB/T2965, GB/T228, GB/T2039, GB/T3620.1, GB/T3620.2, GB/T4338, GB/T4698, GB/T5168,

GB/T5193, GB/T8180, GB/T13810-2007, GB/T2965-2007, ASTM B348, ASTM B381, ASTM F67, ISO5832-2ASTM F136, ISO5832-3, AMS4928, MIL4911, ASTM F1713-08, ASTM F1295, ISO5832- 11

Status

Annealed (M) Hot Working (R) Cold Working (Y) (Annealing, Ultrasonic Testing)

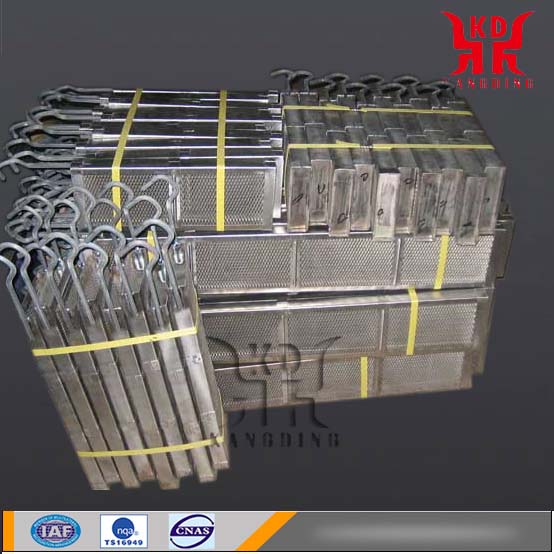

Surface treatment

Forged surface, rolled surface, Light surface, polished surface