The titanium heat exchanger is a heat exchange device made of a high-quality titanium tube that transfers part of the heat of the hot fluid to the cold fluid. Titanium heat exchangers rely on the many advantages of industrial pure titanium, which is a common equipment for chemical, petroleum, power, food and many other industrial sectors, and occupies an important position in production.

Material properties

In practical application, the heat exchange effect of the heat exchanger has a great relationship with the material and process characteristics of the heat exchanger. Material during concentration, solute impurities often heated surface or deposition, to form a scale layer deposited crystals affect the heat transfer; Some solutes are heat-sensitive, and they are prone to deterioration when they stay at high temperatures for too long; Some more corrosive material having a higher viscosity or the like.

Physical properties

Titanium heat exchangers are made of high quality titanium tubes.

In terms of physical properties, titanium tubes have many advantages such as light weight and superior mechanical properties.

The strength of titanium is large, and the tensile strength of pure titanium can reach 180kg/mm2. Some steels have higher strength than titanium alloys, but titanium alloys have higher specific strength (ratio of tensile strength and density) than high-grade steels.

In addition, titanium alloys have good heat resistance, low temperature toughness, and fracture toughness. Titanium pipes perform two national standards in accordance with different requirements and performance:

GB/T3624-1995 GB/T3625-1995.

Supply grades: TA0, TA1, TA2, TA9, TA10

BT1-00, BT1-0

Gr1, Gr2

Chemical properties

In terms of chemical properties, titanium shows good stability and has good corrosion resistance in various industrial solutions. Industrial titanium is an excellent material for refrigeration equipment.

Industrial pure titanium can be widely used in organic compounds, alkali solutions, and salt solutions and other media, and is not easy to react with it, and excellent corrosion resistance; Pure titanium has good corrosion resistance to inorganic acids such as hydrochloric acid, sulfuric acid, and nitric acid at low temperatures at room temperature; However, with the increase of the concentration of the medium and the working temperature, the industrial pure titanium reacts easily with the above-mentioned inorganic acid, so that the corrosion resistance of titanium is reduced. Therefore, the concentration of the medium and the operating temperature should be paid attention to in the heat exchange process.

Industrial pure titanium has good corrosion resistance to organic acids such as formic acid, oxalic acid, and lactic acid at room temperature.

Titanium heat exchanger features

Titanium heat exchanger metal ions are not easy to lose. Therefore, this non-magnetic feature can be fully utilized and used as a heat exchanger for pharmaceutical and food applications.

Due to the strong corrosion resistance of titanium, the heat exchanger has a long service life and is less expensive to use. In addition, because of its small size, large heat transfer capacity and other advantages. The investment and operating costs of associated equipment (eg pumps) can also be reduced accordingly.

Application area

Titanium heat exchangers rely on a variety of excellent properties of industrial pure titanium, Widely used in: All kinds of seafood breeding, sea water heat exchanger, salt water heat exchanger, chemical industry, food, medicine, metallurgy, refrigeration, light industry, electroplating industry, aluminum oxide tank, salt production, papermaking, ultrasonic, electronic communication, central heating Other industries and fields.

specification

Alloying

Titanium alloys are alloys based on titanium added to other elements. Titanium has two different crystals:Below 882°C, close-packed hexagonal α-titanium, and above 882°C, body-centered cubic β-titanium. Alloying elements can be classified into three categories based on their influence on the phase transition temperature:

1. The element that stabilizes the α-phase and raises the phase transition temperature is an α-stabilizing element and includes aluminum, carbon, oxygen, and nitrogen.

Among them, aluminum is the main alloying element of titanium alloy. It has obvious effects on increasing the strength of the alloy at room temperature and high temperature, decreasing the specific gravity and increasing the elastic modulus.

2. The element that stabilizes the β phase and reduces the phase transition temperature is a β-stabilizing element, which can be divided into two types: isomorphous and eutectoid. The former products using titanium alloys include molybdenum, tantalum and vanadium; the latter include chromium, manganese, copper, iron and silicon.

3. The elements that have little effect on the phase transition temperature are neutral elements such as zirconium and tin. Oxygen, nitrogen, carbon and hydrogen are the main impurities of titanium alloys. Oxygen and nitrogen have greater solubility in the α phase, which has a significant strengthening effect on the titanium alloy, but it decreases the plasticity. It is generally specified that the oxygen and nitrogen contents in titanium are respectively 0.15 to 0.2% and 0.04 to 0.05%. The solubility of hydrogen in the alpha phase is very small, and too much dissolved hydrogen in the titanium alloy will produce hydrides, making the alloy brittle. Generally, the hydrogen content in the titanium alloy is controlled below 0.015%. The dissolution of hydrogen in titanium is reversible and can be removed by vacuum annealing.

Material properties

In practical application, the heat exchange effect of the heat exchanger has a great relationship with the material and process characteristics of the heat exchanger. Material during concentration, solute impurities often heated surface or deposition, to form a scale layer deposited crystals affect the heat transfer; Some solutes are heat-sensitive, and they are prone to deterioration when they stay at high temperatures for too long; Some more corrosive material having a higher viscosity or the like.

Physical properties

Titanium heat exchangers are made of high quality titanium tubes.

In terms of physical properties, titanium tubes have many advantages such as light weight and superior mechanical properties.

The strength of titanium is large, and the tensile strength of pure titanium can reach 180kg/mm2. Some steels have higher strength than titanium alloys, but titanium alloys have higher specific strength (ratio of tensile strength and density) than high-grade steels.

In addition, titanium alloys have good heat resistance, low temperature toughness, and fracture toughness. Titanium pipes perform two national standards in accordance with different requirements and performance:

GB/T3624-1995 GB/T3625-1995.

Supply grades: TA0, TA1, TA2, TA9, TA10

BT1-00, BT1-0

Gr1, Gr2

Chemical properties

In terms of chemical properties, titanium shows good stability and has good corrosion resistance in various industrial solutions. Industrial titanium is an excellent material for refrigeration equipment.

Industrial pure titanium can be widely used in organic compounds, alkali solutions, and salt solutions and other media, and is not easy to react with it, and excellent corrosion resistance; Pure titanium has good corrosion resistance to inorganic acids such as hydrochloric acid, sulfuric acid, and nitric acid at low temperatures at room temperature; However, with the increase of the concentration of the medium and the working temperature, the industrial pure titanium reacts easily with the above-mentioned inorganic acid, so that the corrosion resistance of titanium is reduced. Therefore, the concentration of the medium and the operating temperature should be paid attention to in the heat exchange process.

Industrial pure titanium has good corrosion resistance to organic acids such as formic acid, oxalic acid, and lactic acid at room temperature.

Titanium heat exchanger features

Titanium heat exchanger metal ions are not easy to lose. Therefore, this non-magnetic feature can be fully utilized and used as a heat exchanger for pharmaceutical and food applications.

Due to the strong corrosion resistance of titanium, the heat exchanger has a long service life and is less expensive to use. In addition, because of its small size, large heat transfer capacity and other advantages. The investment and operating costs of associated equipment (eg pumps) can also be reduced accordingly.

Application area

Titanium heat exchangers rely on a variety of excellent properties of industrial pure titanium, Widely used in: All kinds of seafood breeding, sea water heat exchanger, salt water heat exchanger, chemical industry, food, medicine, metallurgy, refrigeration, light industry, electroplating industry, aluminum oxide tank, salt production, papermaking, ultrasonic, electronic communication, central heating Other industries and fields.

specification

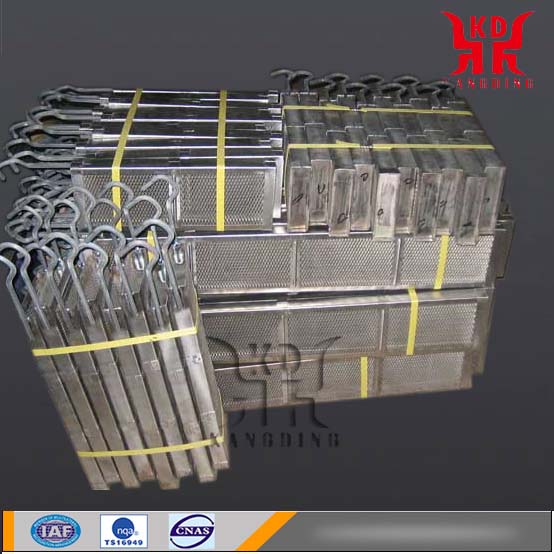

| Heat exchanger fixed tube plate type: TA1 TA2 TA3 Q235-A titanium/steel composite plate |

| Cooler floating head type: TA9 Ta10 Q235-A |

| Condenser U-tube type: Zr0 Zr2 16MnR Zirconium/steel composite plate |

| Network evaporator filler formula: TA1 TA2 20G tantalum / steel composite plate |

|

Heater all-titanium: N2 N4 N6 1Cr18Ni9 Nickel/steel composite plate (Ta1 TA2 TA3 TA9 TA10) |

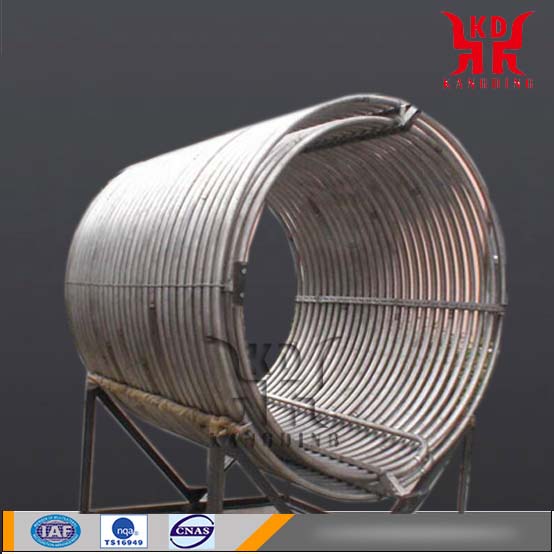

| Heater coil Ta1 TA2 TA3 |

|

Serpentine condenser TA9 Ta10 Zr0 Zr2 TA1 TA2 N2 N4 N6 |

Alloying

Titanium alloys are alloys based on titanium added to other elements. Titanium has two different crystals:Below 882°C, close-packed hexagonal α-titanium, and above 882°C, body-centered cubic β-titanium. Alloying elements can be classified into three categories based on their influence on the phase transition temperature:

1. The element that stabilizes the α-phase and raises the phase transition temperature is an α-stabilizing element and includes aluminum, carbon, oxygen, and nitrogen.

Among them, aluminum is the main alloying element of titanium alloy. It has obvious effects on increasing the strength of the alloy at room temperature and high temperature, decreasing the specific gravity and increasing the elastic modulus.

2. The element that stabilizes the β phase and reduces the phase transition temperature is a β-stabilizing element, which can be divided into two types: isomorphous and eutectoid. The former products using titanium alloys include molybdenum, tantalum and vanadium; the latter include chromium, manganese, copper, iron and silicon.

3. The elements that have little effect on the phase transition temperature are neutral elements such as zirconium and tin. Oxygen, nitrogen, carbon and hydrogen are the main impurities of titanium alloys. Oxygen and nitrogen have greater solubility in the α phase, which has a significant strengthening effect on the titanium alloy, but it decreases the plasticity. It is generally specified that the oxygen and nitrogen contents in titanium are respectively 0.15 to 0.2% and 0.04 to 0.05%. The solubility of hydrogen in the alpha phase is very small, and too much dissolved hydrogen in the titanium alloy will produce hydrides, making the alloy brittle. Generally, the hydrogen content in the titanium alloy is controlled below 0.015%. The dissolution of hydrogen in titanium is reversible and can be removed by vacuum annealing.