Titanium Alloy Sheet Metal Stamping Process

1, a titanium alloy sheet metal stamping process, characterized in that:

(1) The TC4 titanium alloy sheet blank that will need to be stamped is coated with a special glass protective agent for titanium alloy. Placed in a heating furnace (850 ~ 880) °C heating time (6 ~ 8) min;

(2) The forming mold is installed on a common punching machine, the mold is preheated (500-650)°C before stamping, and then the heated blank is rapidly placed into the mold for stamping and forming.

Titanium alloy sheet metal stamping process, which is characterized by:

1, titanium alloy blank heating temperature (850 ~ 880) °C, heating time (6 ~ 8) min.

2, mold preheat temperature (500 ~ 650) °C.

3, the special glass protective agent for surface coating titanium alloy is FR5.

Technical field

The invention relates to a method for manufacturing a titanium alloy sheet metal stamping process, and is particularly suitable for a stamping and deep drawing forming process of a thin-walled TC4 titanium alloy sheet with a thickness of about 1 mm.

Background technique

Titanium alloy sheet forming has always been a research topic for new materials and new processes at home and abroad. Because the titanium alloy is easy to crack when it is deformed, it is impossible to carry it out in the cold state, and it can only be shaped in the hot state. However, heat forming imposes higher requirements and problems on equipment, mold materials and structures, and production processes.

Titanium alloys developed rapidly at the end of the 20th century.

Titanium alloys are mainly used in aerospace applications. In the United States and Europe, titanium alloys are widely used in aircraft such as F-22, gusts, and Euro 2000. Among them, the superplastic forming/diffusing connection technology of titanium alloy is not only used for the manufacture of flaps, hatches, but also for leading edge slats, duck wings, and deceleration plates. China's advanced aircraft pelvic fins, flaps and engine rectifying blades and advanced missile missile components also use titanium alloy thin-walled structures.

Although there have been significant advances in superplastic forming, thermoforming technology, and chemical milling techniques for titanium alloys in China, However, most titanium alloy parts are still mainly machined, while fewer parts are stamped and formed. In addition, a hot creep forming process is required, and a special hot creep forming machine is required, which is expensive and costly.

Summary of the Invention

The technical problem to be solved by the present invention is to provide a titanium alloy sheet metal stamping forming process, which solves the problem that the titanium alloy sheet such as TC4 is expensive to pass through a thermal creep forming machine.

In order to solve the above problems, the present invention adopts the following technical solutions:

Description of the drawings

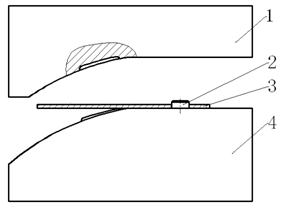

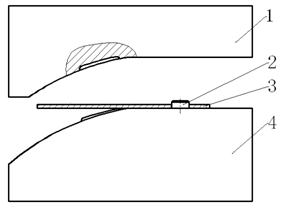

figure 1. Titanium alloy sheet forming, arm product schematic.

figure 2. Titanium alloy plate forming die diagram.

In Fig. 2, 1, upper mold, 2, positioning pin, 3, titanium alloy blank, 4, lower mold.

The mold is mounted on a universal punch and the heated titanium alloy blank is placed in the lower mold cavity. The punch press is started so that the upper and lower molds press the blank to form a part.

(1) The TC4 titanium alloy sheet blank that will need to be stamped is coated with a special glass protective agent for titanium alloy. Placed in a heating furnace (850 ~ 880) °C heating time (6 ~ 8) min;

(2) The forming mold is installed on a common punching machine, the mold is preheated (500-650)°C before stamping, and then the heated blank is rapidly placed into the mold for stamping and forming.

Titanium alloy sheet metal stamping process, which is characterized by:

1, titanium alloy blank heating temperature (850 ~ 880) °C, heating time (6 ~ 8) min.

2, mold preheat temperature (500 ~ 650) °C.

3, the special glass protective agent for surface coating titanium alloy is FR5.

Technical field

The invention relates to a method for manufacturing a titanium alloy sheet metal stamping process, and is particularly suitable for a stamping and deep drawing forming process of a thin-walled TC4 titanium alloy sheet with a thickness of about 1 mm.

Background technique

Titanium alloy sheet forming has always been a research topic for new materials and new processes at home and abroad. Because the titanium alloy is easy to crack when it is deformed, it is impossible to carry it out in the cold state, and it can only be shaped in the hot state. However, heat forming imposes higher requirements and problems on equipment, mold materials and structures, and production processes.

Titanium alloys developed rapidly at the end of the 20th century.

Titanium alloys are mainly used in aerospace applications. In the United States and Europe, titanium alloys are widely used in aircraft such as F-22, gusts, and Euro 2000. Among them, the superplastic forming/diffusing connection technology of titanium alloy is not only used for the manufacture of flaps, hatches, but also for leading edge slats, duck wings, and deceleration plates. China's advanced aircraft pelvic fins, flaps and engine rectifying blades and advanced missile missile components also use titanium alloy thin-walled structures.

Although there have been significant advances in superplastic forming, thermoforming technology, and chemical milling techniques for titanium alloys in China, However, most titanium alloy parts are still mainly machined, while fewer parts are stamped and formed. In addition, a hot creep forming process is required, and a special hot creep forming machine is required, which is expensive and costly.

Summary of the Invention

The technical problem to be solved by the present invention is to provide a titanium alloy sheet metal stamping forming process, which solves the problem that the titanium alloy sheet such as TC4 is expensive to pass through a thermal creep forming machine.

In order to solve the above problems, the present invention adopts the following technical solutions:

Description of the drawings

figure 1. Titanium alloy sheet forming, arm product schematic.

figure 2. Titanium alloy plate forming die diagram.

In Fig. 2, 1, upper mold, 2, positioning pin, 3, titanium alloy blank, 4, lower mold.

The mold is mounted on a universal punch and the heated titanium alloy blank is placed in the lower mold cavity. The punch press is started so that the upper and lower molds press the blank to form a part.