LED Aluminum Heat Dissipation Board Technology

The thermal conductivity of led Al base board is related to the insulation layer in the middle of the aluminum substrate (generally PP, now with thermal conductive adhesive, etc.). It is one of the three standards to measure the quality of Al base board, (The thermal resistance and pressure resistance are the other two properties). After the plate is pressed together, the Al base board thermal conductivity can be measured by the test equipment. The current high thermal conductivity is generally ceramics, copper, etc. However, due to cost considerations, the current mainstream in the market is the electronic Al base board, The corresponding Al base board thermal conductivity is a parameter that everyone cares about. The higher the thermal conductivity, the better the representative performance.

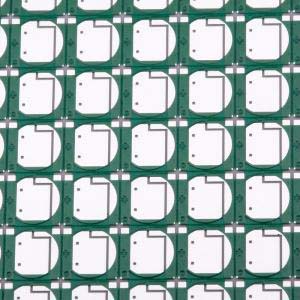

1. Using surface mount technology (the SMT); membrane ring Al base board

2. Perform extremely effective processing of thermal diffusion in circuit design schemes;

3. Reduce product operating temperature, improve product power density and reliability, and extend product life;

4. Reduce product volume, reduce hardware and assembly costs;

5. Replace brittle ceramic substrates for better mechanical durability.

LED Al base board products are widely used in communications, power, electronics, medical equipment, machinery and equipment, lighting and other fields. With the rising awareness of global environmental protection, energy saving and power saving have become the current trend. LED industry is one of the most watched industries in recent years. Since its development, LED products have become energy-efficient, energy-saving, high-efficiency, fast response time, long life cycle, and no mercury, and they have environmental benefits. However, usually about 20% of input power of LED high-power products can be converted into light, and 80% of the remaining power is converted into heat energy.

In general, if the heat generated by the LED while emitting light cannot be dissipated, the junction temperature of the LED will be too high, which will affect the product life cycle, luminous efficiency, and stability. The relationship between LED junction temperature, luminous efficiency, and lifetime will be further explained using the relationship below.

1, LED heat dissipation methods are based on different packaging technologies, and their heat dissipation methods are also different. However, LED heat dissipation methods can be approximated as follows:

Thermal path description:

(1). Heat dissipation from the air

(2). Thermal energy is directly derived from the System circuit board

(3). The energy export via the gold wire

(4). If the eutectic and Flip chip process, the thermal energy is derived via the through hole of the circuit board to the system

1, LED heat dissipation methods are based on different packaging technologies, and their heat dissipation methods are also different. However, LED heat dissipation methods can be approximated as follows:

Thermal path description:

(1). Heat dissipation from the air

(2). Thermal energy is directly derived from the System circuit board

(3). The energy export via the gold wire

(4). If the eutectic and Flip chip process, the thermal energy is derived via the through hole of the circuit board to the system

However, the bottleneck of heat dissipation in the entire system at the present stage is mostly the conduction of heat from the LED die to its substrate to the system circuit board.

Possible cooling paths in this section: One is to directly dissipate heat from the die substrate to the system board. In this heat dissipation method, the heat dissipation capability of the LED die substrate material is a very important parameter. On the other hand, the heat generated by the LED will also go to the system circuit board through the electrode metal wire. In general, under the electrode bonding using the gold wire method, the heat dissipation is limited by the relatively slender geometry of the metal wire itself; As a result, there has recently been a eutectic or flip-chip bonding approach. This design significantly reduces the length of the wire and significantly increases the cross-sectional area of the wire. As a result, the heat dissipation efficiency from the LED electrode wires to the system board will be effectively improved.

Through the explanation of the above heat-dissipation path, it can be seen that the choice of heat-dissipating substrate material and the packaging method of its LED die account for a very important part in the management of LED heat dissipation. The following section will outline the LED heat-dissipating substrate.

The LED heat-dissipating substrate mainly uses the heat-dissipating substrate material itself to have better thermal conductivity, and the heat source is led out from the LED die. Therefore, from the description of LED heat dissipation methods, LED heat sink substrates can be subdivided into two major categories, namely, LED grain substrate and system circuit boards. The two different heat-dissipating substrates bear the heat energy generated when the LED die and the LED chip emit light from the LED die, respectively. Through the LED die heat sink substrate to the system circuit board, and then absorbed by the atmospheric environment, in order to achieve the effect of heat dissipation.

2.1 system circuit board

The system circuit board is mainly used as an LED heat dissipation system, and finally conducts heat energy to the heat sink fins, the housing, or the atmosphere. In recent years, the production technology of printed circuit boards (PCBs) has become very sophisticated. The system circuit boards of early LED products are mainly PCBs. However, as the demand for high-power LEDs increases, the heat dissipation capacity of PCB materials is limited, making it impossible to apply them. Its high-power products, In order to improve the heat dissipation of high-power LEDs, a high thermal conductivity aluminum substrate (MCPCB) has recently been developed. The use of metal materials with better heat dissipation characteristics has achieved the purpose of heat dissipation for high-power products. However, with the continuous development of LED brightness and performance requirements, although the system circuit board can effectively heat the heat generated by the LED chip to the atmosphere, However, the thermal energy generated by the LED die cannot be effectively transferred from the die to the system board. In other words, when the LED power is increased more efficiently, the heat-dissipation bottleneck of the entire LED will appear on the LED die heat-dissipating substrate.

2.2LED die substrate

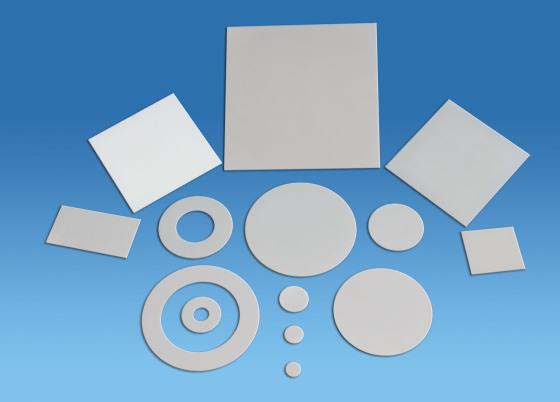

The LED die substrate is mainly used as a medium derived from the thermal energy between the LED die and the system circuit board, and is combined with the LED die by a process of wire bonding, eutectic or flip chip bonding. Based on thermal considerations, the current market for LED die substrates is mainly ceramic substrates.

The line preparation methods can be roughly divided into:

Thick film ceramic substrates, low temperature co-fired multilayer ceramics, and thin film ceramic substrates. In traditional high-power LED devices, thick-film or low-temperature co-fired ceramic substrates are mostly used as the heat sink substrate for the crystal grains, and the LED crystal grains are combined with the ceramic substrate by gold wire.

As mentioned in the introduction, this gold wire connection limits the heat dissipation along the electrode contact. Therefore, in recent years, major manufacturers at home and abroad have all worked hard to solve this problem. There are two ways to solve it: One is to find a substrate material with a high heat dissipation coefficient to replace aluminum oxide, which includes a tantalum substrate, a tantalum carbide substrate, an anodized aluminum substrate, or an aluminum nitride substrate.

Among them, the material and semiconductor properties of germanium and silicon carbide substrates have caused them to face severe challenges at this stage. The anodized aluminum substrate is susceptible to cracking due to insufficient strength of the anodized oxide layer, which limits its practical application. Therefore, aluminum nitride is used as a heat-dissipating substrate at the present stage, which is mature and generally accepted; However, it is currently limited to aluminum nitride substrates that are not suitable for conventional thick-film processes (the materials must be subjected to atmospheric heat treatment at 850°C after printing of the silver paste, which causes material reliability problems). Therefore, the aluminum nitride substrate circuit needs to be prepared by a thin film process.

The aluminum nitride substrate prepared by thin film process greatly accelerates the performance of heat from the LED die through the substrate material to the system circuit board. Therefore, the heat is greatly reduced by the burden of the LED die through the metal line to the system circuit board, thereby achieving a high heat dissipation effect.

LED aluminum substrate product projects cover the entire industry of lighting products, such as commercial lighting, indoor lighting. The overall situation, LED aluminum substrate in the next few years still maintain rapid development, the amount of exports will grow steadily, but the decline in export growth. Domestic sales have ushered in a period of rapid growth due to the continued economic development.

However, the development of the LED aluminum substrate industry in China in the past five years has also caused fierce competition. Due to LED lighting related technologies and thermal performance, LED development in the domestic market is slow, Most of the LED lighting is used for export. In this regard, LED aluminum substrates are constantly being developed for space and time. Under the guidance of the country's vigorous efforts in the future, LED aluminum substrate technology will be more and more perfect, domestic demand will increase.