Automotive Stamping Manufacturing Process

Maybe the rush, my intention in just about the car, I would like to say to everyone that it is not just the history of the development of automobiles. I would like to say second-hand cars, auto repair, automobile manufacturing and new energy. However, when registering the number of the headline, I forgot to think about it. Here is a description. I will systematically introduce you to the knowledge about the car. In the following days, the four major technologies for automobile manufacturing (pressing, welding, painting, assembly) will be introduced. In the future, we will continue to introduce others such as automotive new energy.

People are fickle, and the noble head who had just fallen yesterday will be high today. After deciding, we must write what we want to write in the future, and we should not cater to those so-called unspoken rules. Please forgive me for liberty in my life. As the night falls and the neon flashes, one travels between the school and the Southeast Auto Factory and looks out at the car window. I think that many people have seen cars, but not everyone knows how cars were made. After all, related auto majors are also opened in the last decade. Therefore, I would like people to like it even if I talk to you about making cars. The main reason is that talked about the car not to mention the car manufacturers can not be justified. Yesterday's stamping was very simple to write. The mistake that I made yesterday was back to the pot today. I hope I can write it slightly better.

A car from scratch, the car contains numerous large and small parts, how it was created out of it?

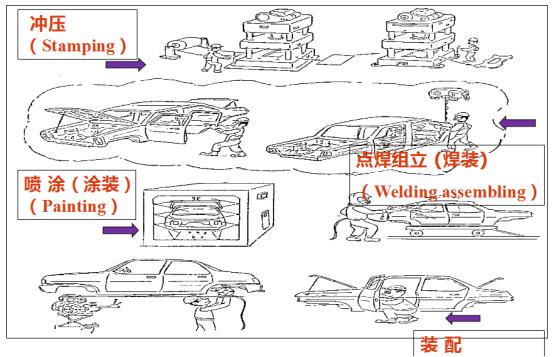

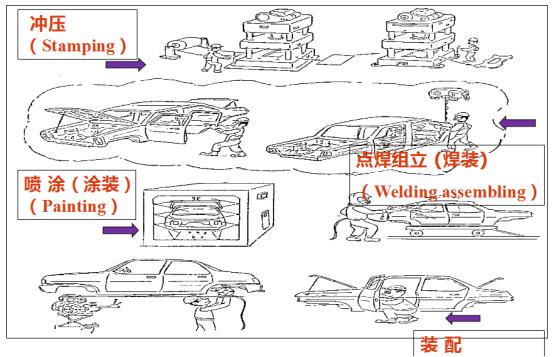

Simply put together the four major car manufacturing processes to answer this question.

The automobile factory punches the steel coils out of various types of sheet metal parts (such as a five-door cover, a leaf board, a ceiling, etc.) that make up the body through punching equipment such as punch presses and stamping dies; Immediately after the sheet metal parts were sent to the welding shop for body assembly. The equipment used here is mainly welding torches, fixtures, robots, With the development of industrial technology, more and more artificial spot welding operations will be replaced by robots; After the completion of the assembly, the body is sent to the coating. The coating is a gathering place for the core technology of a car manufacturer. The general coating will be sprayed at least three times. The first layer is mainly ED layer used for rust prevention, the other two layers are mainly used for aesthetics; After the painting is finished, it will be at the final station of the final assembly station. The final assembly will mainly be to assemble various accessories on the car body. such as engine transmission suspension tires and so on. After the final assembly, a car is basically finished production, but after the final assembly, the car must undergo some rigorous tests. Only the vehicles passing the test can be finally delivered to the customer.

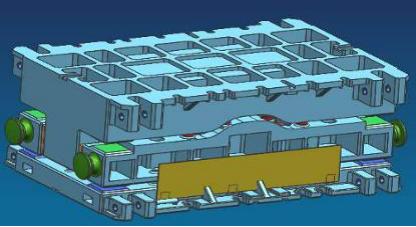

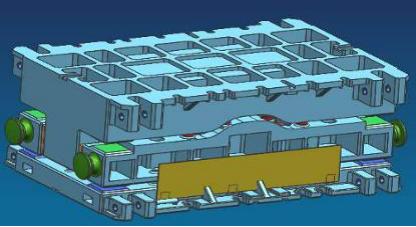

Mold, In industrial production, various molds and tools for the desired products are obtained by injection molding, blow molding, extrusion, die casting or forging, smelting, stamping, and the like. In a narrow sense, automobile molds are the general name for the stamping of all the stamping parts on a car body. Next, we will also provide a few pictures to let everyone have a more sensorial understanding of the car stamping die.

The green ones in the picture are the car molds, during the production process, The die and the press machine cooperate to press the steel plate, Different molds punch out different automotive sheet metal parts. The main equipment has been roughly described. Now I will begin to explain the main work flow of the press shop.

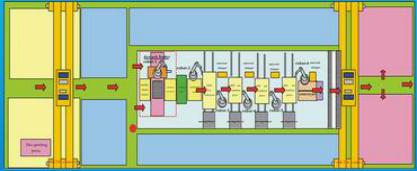

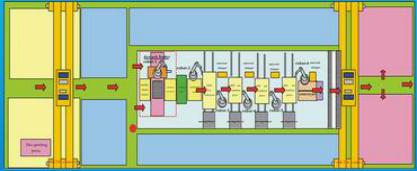

First, the purchased steel plate is sent to the stamping line for cleaning by the washing machine, and then transferred by the robot arm to the next station, that is, the first station for stamping. Then it is sent to the next station for trimming, followed by punching, and then folding. These operations are all completed automatically. The final receipt is done manually because of the quality inspection and loading of stamped sheet metal parts. There are also five stamping presses for a stamping production line in a car factory. It may be said that everyone will still feel the shortcomings. Then it is time to witness miracles. Please see this picture

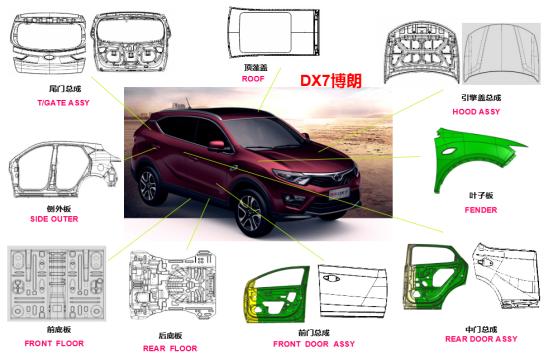

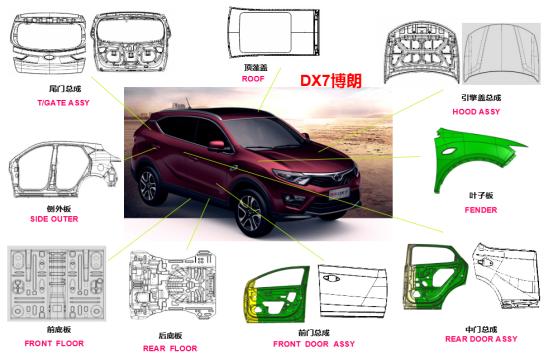

The car is actually made up of many pieces of sheet metal. Everyone who knows the most is sure to understand that there are four doors and two covers, as well as fenders, baseboards, tail beams, and so on, all of which were produced by the press shop through the above process. Simply saying that the stamping shop, is through different molds loaded on the stamping machine to press the steel sheet into different sheet metal parts, this is the main work of the automotive stamping shop. nIn fact, in order to ensure the normal production of sheet metal parts, There is still a lot of work to be done, such as equipment maintenance, mold maintenance, These repairs are not introduced, because these jobs are all for the normal production of high-quality sheet metal parts.

People are fickle, and the noble head who had just fallen yesterday will be high today. After deciding, we must write what we want to write in the future, and we should not cater to those so-called unspoken rules. Please forgive me for liberty in my life. As the night falls and the neon flashes, one travels between the school and the Southeast Auto Factory and looks out at the car window. I think that many people have seen cars, but not everyone knows how cars were made. After all, related auto majors are also opened in the last decade. Therefore, I would like people to like it even if I talk to you about making cars. The main reason is that talked about the car not to mention the car manufacturers can not be justified. Yesterday's stamping was very simple to write. The mistake that I made yesterday was back to the pot today. I hope I can write it slightly better.

A car from scratch, the car contains numerous large and small parts, how it was created out of it?

Simply put together the four major car manufacturing processes to answer this question.

The automobile factory punches the steel coils out of various types of sheet metal parts (such as a five-door cover, a leaf board, a ceiling, etc.) that make up the body through punching equipment such as punch presses and stamping dies; Immediately after the sheet metal parts were sent to the welding shop for body assembly. The equipment used here is mainly welding torches, fixtures, robots, With the development of industrial technology, more and more artificial spot welding operations will be replaced by robots; After the completion of the assembly, the body is sent to the coating. The coating is a gathering place for the core technology of a car manufacturer. The general coating will be sprayed at least three times. The first layer is mainly ED layer used for rust prevention, the other two layers are mainly used for aesthetics; After the painting is finished, it will be at the final station of the final assembly station. The final assembly will mainly be to assemble various accessories on the car body. such as engine transmission suspension tires and so on. After the final assembly, a car is basically finished production, but after the final assembly, the car must undergo some rigorous tests. Only the vehicles passing the test can be finally delivered to the customer.

What is stamping?

Pressing is the application of external force to the plate, strip, pipe, and profile by presses and dies, so that plastic deformation or separation occurs. Thus, a method of forming a workpiece having a desired shape and size is obtained.

When it comes to stamping, then we first talk about the equipment punching machines and molds that are mainly used, as well as some other transportation equipment. In the press shop, these two devices are the most valuable. Now it is necessary to invest in a stamping production line that is at least hundreds of millions. More technical content is the mold manufacturing and mold repair. Let's look at the pictures of these devices first.

Press is driven by the motor flywheel, and through the clutch, The driving gear drives the crank connecting rod mechanism to move the slider up and down, driving the stretching die to form the steel plate. Stamping machine press is one of the most important and commonly used equipment in the four major processes of automobile manufacturing. It mainly relies on the pressing energy of the press to work on the steel plate in the mold to form it into the shell of the automobile body.

Pressing is the application of external force to the plate, strip, pipe, and profile by presses and dies, so that plastic deformation or separation occurs. Thus, a method of forming a workpiece having a desired shape and size is obtained.

When it comes to stamping, then we first talk about the equipment punching machines and molds that are mainly used, as well as some other transportation equipment. In the press shop, these two devices are the most valuable. Now it is necessary to invest in a stamping production line that is at least hundreds of millions. More technical content is the mold manufacturing and mold repair. Let's look at the pictures of these devices first.

Press is driven by the motor flywheel, and through the clutch, The driving gear drives the crank connecting rod mechanism to move the slider up and down, driving the stretching die to form the steel plate. Stamping machine press is one of the most important and commonly used equipment in the four major processes of automobile manufacturing. It mainly relies on the pressing energy of the press to work on the steel plate in the mold to form it into the shell of the automobile body.

Mold, In industrial production, various molds and tools for the desired products are obtained by injection molding, blow molding, extrusion, die casting or forging, smelting, stamping, and the like. In a narrow sense, automobile molds are the general name for the stamping of all the stamping parts on a car body. Next, we will also provide a few pictures to let everyone have a more sensorial understanding of the car stamping die.

The green ones in the picture are the car molds, during the production process, The die and the press machine cooperate to press the steel plate, Different molds punch out different automotive sheet metal parts. The main equipment has been roughly described. Now I will begin to explain the main work flow of the press shop.

First, the purchased steel plate is sent to the stamping line for cleaning by the washing machine, and then transferred by the robot arm to the next station, that is, the first station for stamping. Then it is sent to the next station for trimming, followed by punching, and then folding. These operations are all completed automatically. The final receipt is done manually because of the quality inspection and loading of stamped sheet metal parts. There are also five stamping presses for a stamping production line in a car factory. It may be said that everyone will still feel the shortcomings. Then it is time to witness miracles. Please see this picture

The car is actually made up of many pieces of sheet metal. Everyone who knows the most is sure to understand that there are four doors and two covers, as well as fenders, baseboards, tail beams, and so on, all of which were produced by the press shop through the above process. Simply saying that the stamping shop, is through different molds loaded on the stamping machine to press the steel sheet into different sheet metal parts, this is the main work of the automotive stamping shop. nIn fact, in order to ensure the normal production of sheet metal parts, There is still a lot of work to be done, such as equipment maintenance, mold maintenance, These repairs are not introduced, because these jobs are all for the normal production of high-quality sheet metal parts.