3D Glass CNC Equipment Usher in New Opportunities

Introduction: 3D glass seems to be the trend of choice for mobile terminals, and the trend of terminals will often influence the changes in the industry chain. Some researchers believe that the market demand for 3D glass processing and its related processing equipment manufacturing will exceed 100 billion yuan.

Since the advent of the Samsung Galaxy 3D curved screen mobile phone in 2015, the market for 3D curved glass cover plates has been strongly attacked, and sales in the mobile phone market have been showing a fierce trend. Under the strong limelight, domestic and foreign brands followed suit and launched 3D glass cover phones.

The reason why 3D curved glass is so popular, thanks to its thin, simple, transparent and surface anti-fingerprint design, Coupled with a strong addition to its three-dimensional, straight grip and a sense of beauty, but also because both sides of the arc allows mobile phone brands to consider more applications at design time. 3D glass seems to be the trend of choice for mobile terminals, and the trend of terminals will often affect the changes in the industry chain. Some researchers believe that the market demand for 3D glass processing and its related processing equipment manufacturing will exceed 100 billion RMB.

Wireless charging +5G+AMOLED, the future is glass

From Samsung, Huawei, ViVo, OPPO, Xiaomi, Jinli, etc., 3D glass covers are used in more and more models of some brands. The momentum seems to be that in the mobile phone industry, the future will be glass. Overall, what factors make many people inside and outside the industry to foresee the dividends in the 3D glass field? The author summarizes mainly three factors, namely wireless charging, 5G technology and AMOLED.

As we all know, Samsung Gear Watch, S6 series and S7 series, as well as Apple Apple Watch, Apple8, Apple8plus, AppleX have already achieved wireless charging technology, wireless charging has become an important gimmick for these products promotion momentum. And regardless of their practicality, it does bring new highlights or selling points in the current state of mobile phone homogenization. As the traditional leader in the mobile phone industry, Apple's terminal products will undoubtedly become the vane of the industry, and will inevitably drive other brands to try on wireless charging. In fact, according to a newspaper reporter, there are already a lot of wireless equipment manufacturers in China that have already obtained a lot of financing and are ready to go. They are confident that they are ready to welcome this delicious cake.

The basic principle of wireless charging is the use of electromagnetic waves, but existing metal housings can absorb and shield electromagnetic waves, greatly reducing the charging efficiency, and the glass has no such problem at all. Another kind of material with small electromagnetic wave shielding and shielding ability is a ceramic case, but at present, the requirements for large-scale production cannot be met from the aspects of cost, productivity, and yield, and glass is acceptable.

In addition, whether it is from the national policy or the layout of the industry, the 5G era has become a clear trend. 5G is to use higher frequency to increase bandwidth, but the higher frequency wavelength is lower, so the diffraction ability is worse and the difficulty of mobile phone signal reception is increased. In this case, the shielding of the signal can only be reduced by relying on the design of the mobile phone cover, and the traditional metal back cover is undoubtedly much worse than the glass. Therefore, it can be predicted that the advantages of the glass back cover will be more prominent in the 5G era. In addition, AMOLED is also the next generation of display technology. Its distinguishing feature is flexibly bendable, 3D glass panel it is the best match. And now many brands have begun to try this technology. Thus, in the field of mobile phone covers, industry trends have shown that the future is the world of glass.

3D Glass Technology: Pulling Hot Bends

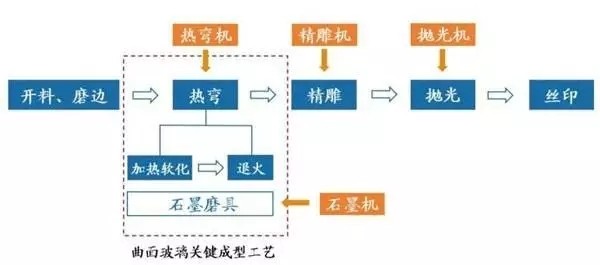

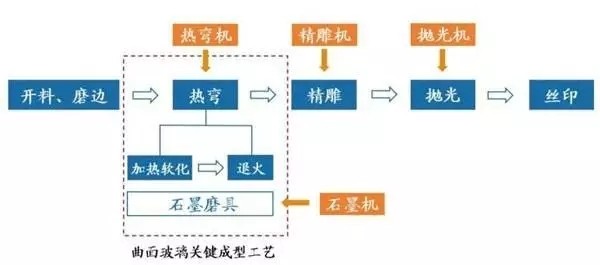

From the manufacturing process of the mobile phone cover, it mainly includes cutting, edging, carving, polishing and silk screen printing. From a technical point of view, the main difference between 3D curved glass covers and traditional 2D and 2.5D is that the manufacturing process of 3D curved glass has one more hot bending process, as shown in the following figure:

The importance of 3D hot bend forming technology can be summarized in one sentence, that is, it directly determines whether the entire 3D glass project can be carried out smoothly. And this is because of the hot bending section, the good quality rate directly determines the yield of 3D glass cover. Due to the relatively high threshold of the technology, the current domestic hot bending machines for producing 3D curved glass are mainly imported Korean equipment, and the production capacity is far from meeting the market demand. Therefore, accelerating the development of hot bending machines, improving the yield of hot bend manufacturing, and expanding the market for curved surfaces have become the future choice for many companies.

In addition, 3D hot-bending molding also requires the selection of graphite mold materials, graphite mold design, mold processing, bending parameters of the equipment, etc., with the close cooperation of relevant personnel. Among them, the graphite processing bed is of vital importance and has become a key product for many companies. According to the author's understanding, the JTGK-600FS high-precision graphite processing machine of Guangdong Jiatie Company adopts a graphite dry cutting (blowing) process. Good sealing performance inside, coupled with a powerful dust collection device, can prevent the graphite powder from affecting the machine parts. It is worth mentioning that the three-dimensional contour accuracy of the product can meet the requirements of curved hot bending glass molds, and the market prospect can be imagined.

In addition to the hot bending technology, under the tide of 3D curved glass, technically it also poses new challenges for CNC processing equipment. Traditional metal CNC is the first choice to achieve the transition to glass CNC or both, how to achieve the balance between the two is a problem placed in front of many CNC equipment manufacturers.

From the perspective of Guangdong Jiatie's products, under the tide of dealing with 3D curved glass, its equipment products also have their own advantages. For example, the company's JTGK-500E engraving and milling machine product, will make a comprehensive improvement in performance and structure, It can provide excellent cutting ability, high-efficiency and high-precision processing results, reduce the vibration during machining and increase the processing speed and feed speed. It is understood that this product is suitable for both aluminum alloy and glass.

It can be seen that in response to the wave of 3D curved glass cover plates, Guangdong Jiatie Company did not abandon metal CNC equipment like the strategy of many existing equipment companies. In fact, metal CNC equipment still has a vast market space. This is because 3D glass has its own technical defects, and it is difficult to realize full glass design for a time. Many mobile phone terminals still use the design scheme of “front and back glass + metal middle frame”. This is the development trend of high-end machines. In addition, the metal cover plate will gradually shift to low-end machines and the market is huge.

Therefore, it can be inferred that metal CNC equipment manufacturers will usher in the "post-metal era" of the spring, while the glass CNC technology can also show its talent in the trend of 3D glass. This shows that for CNC equipment manufacturers, the market's profit margin is still huge.

Since the advent of the Samsung Galaxy 3D curved screen mobile phone in 2015, the market for 3D curved glass cover plates has been strongly attacked, and sales in the mobile phone market have been showing a fierce trend. Under the strong limelight, domestic and foreign brands followed suit and launched 3D glass cover phones.

The reason why 3D curved glass is so popular, thanks to its thin, simple, transparent and surface anti-fingerprint design, Coupled with a strong addition to its three-dimensional, straight grip and a sense of beauty, but also because both sides of the arc allows mobile phone brands to consider more applications at design time. 3D glass seems to be the trend of choice for mobile terminals, and the trend of terminals will often affect the changes in the industry chain. Some researchers believe that the market demand for 3D glass processing and its related processing equipment manufacturing will exceed 100 billion RMB.

Wireless charging +5G+AMOLED, the future is glass

From Samsung, Huawei, ViVo, OPPO, Xiaomi, Jinli, etc., 3D glass covers are used in more and more models of some brands. The momentum seems to be that in the mobile phone industry, the future will be glass. Overall, what factors make many people inside and outside the industry to foresee the dividends in the 3D glass field? The author summarizes mainly three factors, namely wireless charging, 5G technology and AMOLED.

As we all know, Samsung Gear Watch, S6 series and S7 series, as well as Apple Apple Watch, Apple8, Apple8plus, AppleX have already achieved wireless charging technology, wireless charging has become an important gimmick for these products promotion momentum. And regardless of their practicality, it does bring new highlights or selling points in the current state of mobile phone homogenization. As the traditional leader in the mobile phone industry, Apple's terminal products will undoubtedly become the vane of the industry, and will inevitably drive other brands to try on wireless charging. In fact, according to a newspaper reporter, there are already a lot of wireless equipment manufacturers in China that have already obtained a lot of financing and are ready to go. They are confident that they are ready to welcome this delicious cake.

The basic principle of wireless charging is the use of electromagnetic waves, but existing metal housings can absorb and shield electromagnetic waves, greatly reducing the charging efficiency, and the glass has no such problem at all. Another kind of material with small electromagnetic wave shielding and shielding ability is a ceramic case, but at present, the requirements for large-scale production cannot be met from the aspects of cost, productivity, and yield, and glass is acceptable.

In addition, whether it is from the national policy or the layout of the industry, the 5G era has become a clear trend. 5G is to use higher frequency to increase bandwidth, but the higher frequency wavelength is lower, so the diffraction ability is worse and the difficulty of mobile phone signal reception is increased. In this case, the shielding of the signal can only be reduced by relying on the design of the mobile phone cover, and the traditional metal back cover is undoubtedly much worse than the glass. Therefore, it can be predicted that the advantages of the glass back cover will be more prominent in the 5G era. In addition, AMOLED is also the next generation of display technology. Its distinguishing feature is flexibly bendable, 3D glass panel it is the best match. And now many brands have begun to try this technology. Thus, in the field of mobile phone covers, industry trends have shown that the future is the world of glass.

3D Glass Technology: Pulling Hot Bends

From the manufacturing process of the mobile phone cover, it mainly includes cutting, edging, carving, polishing and silk screen printing. From a technical point of view, the main difference between 3D curved glass covers and traditional 2D and 2.5D is that the manufacturing process of 3D curved glass has one more hot bending process, as shown in the following figure:

The importance of 3D hot bend forming technology can be summarized in one sentence, that is, it directly determines whether the entire 3D glass project can be carried out smoothly. And this is because of the hot bending section, the good quality rate directly determines the yield of 3D glass cover. Due to the relatively high threshold of the technology, the current domestic hot bending machines for producing 3D curved glass are mainly imported Korean equipment, and the production capacity is far from meeting the market demand. Therefore, accelerating the development of hot bending machines, improving the yield of hot bend manufacturing, and expanding the market for curved surfaces have become the future choice for many companies.

In addition, 3D hot-bending molding also requires the selection of graphite mold materials, graphite mold design, mold processing, bending parameters of the equipment, etc., with the close cooperation of relevant personnel. Among them, the graphite processing bed is of vital importance and has become a key product for many companies. According to the author's understanding, the JTGK-600FS high-precision graphite processing machine of Guangdong Jiatie Company adopts a graphite dry cutting (blowing) process. Good sealing performance inside, coupled with a powerful dust collection device, can prevent the graphite powder from affecting the machine parts. It is worth mentioning that the three-dimensional contour accuracy of the product can meet the requirements of curved hot bending glass molds, and the market prospect can be imagined.

In addition to the hot bending technology, under the tide of 3D curved glass, technically it also poses new challenges for CNC processing equipment. Traditional metal CNC is the first choice to achieve the transition to glass CNC or both, how to achieve the balance between the two is a problem placed in front of many CNC equipment manufacturers.

From the perspective of Guangdong Jiatie's products, under the tide of dealing with 3D curved glass, its equipment products also have their own advantages. For example, the company's JTGK-500E engraving and milling machine product, will make a comprehensive improvement in performance and structure, It can provide excellent cutting ability, high-efficiency and high-precision processing results, reduce the vibration during machining and increase the processing speed and feed speed. It is understood that this product is suitable for both aluminum alloy and glass.

It can be seen that in response to the wave of 3D curved glass cover plates, Guangdong Jiatie Company did not abandon metal CNC equipment like the strategy of many existing equipment companies. In fact, metal CNC equipment still has a vast market space. This is because 3D glass has its own technical defects, and it is difficult to realize full glass design for a time. Many mobile phone terminals still use the design scheme of “front and back glass + metal middle frame”. This is the development trend of high-end machines. In addition, the metal cover plate will gradually shift to low-end machines and the market is huge.

Therefore, it can be inferred that metal CNC equipment manufacturers will usher in the "post-metal era" of the spring, while the glass CNC technology can also show its talent in the trend of 3D glass. This shows that for CNC equipment manufacturers, the market's profit margin is still huge.